A PID Temperature Controller: A Comprehensive Guide

Learn how to program a PID temperature controller with this detailed guide. Understand PID control principles, wiring, programming, and practical applications for precise temperature regulation.

1. Introduction

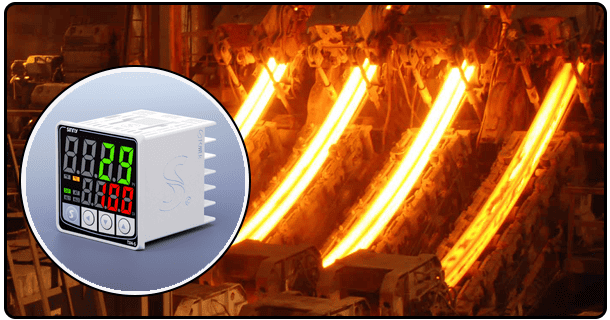

PID (Proportional-Integral-Derivative) controllers are essential tools in many industries for maintaining precise temperature regulation, from industrial ovens and brewing systems, through incubators. Learning the art of programming a PID temperature controller can significantly enhance both its effectiveness and accuracy during temperature regulation processes.

2. Understanding PID Control

PID control is an innovative method that utilizes three separate components - Proportional, Integral, and Derivative. The Proportional component adjusts output proportionally to any errors between desired setpoint temperature and actual temperature; Integral accumulates past errors to eliminate residual steady-state errors; Derivative predicts future errors according to rate of change to provide damping effect and avoid overshoots in output temperature levels;

3. Components Needed

* Power Supply: Ensuring all components receive sufficient power.

* Microcontroller (Optional): Arduino can provide customized configurations and added programming flexibility, offering customisable solutions and additional programming freedom.

Proper wiring of the PID Controller Proper installation and wiring are key to the successful functioning of a PID temperature controller, so follow these steps when connecting yours:

1. Connect a Temperature Sensor: Attach the sensor to your PID controller according to manufacturer's instructions; ensure secure connections for accurate readings and avoid inaccurate readings.

2. Connect the Heating/Cooling Element: Attach your heating or cooling element directly to the output terminals of a PID controller, making sure its specifications align with those of its output terminals.

This section details power connections. When connecting power supplies to PID controllers or components that use electricity, be sure to use proper fuses or circuit breakers in order to protect against electrical faults.

4.Programming the PID Controller

Setting and Configuring PID Parameters Programming a PID controller involves configuring its desired temperature setting as the setpoint and configuring PID parameters - here is an illustrated step-by-step guide:

Select Your Target Temperature: Entering in your target temperature into the PID controller is necessary in order to maintain it. This temperature represents what you wish to maintain as your ideal condition.

Tune PID Parameters: Adjust Proportional, Integral and Derivative values as directed by your manufacturer's recommendations before fine-tuning for optimal temperature changes response. You should begin with their recommended settings then fine tune to meet specific application needs.

Testing and Tuning: Once installed, test and tune your system by watching how it responds to changes in temperature. As necessary, adjust PID parameters until stable, accurate control is reached - this may take multiple iterations before reaching optimal performance.

PID temperature controllers have many practical uses in everyday life. Here are just a few: (* Industrial Ovens (TM): Provide accurate temperatures for baking, curing or drying processes

* Brewing Systems: For consistent product quality, fermentation and brewing temperatures need to be kept under tight control in order to create consistent quality results.

* Incubators provide stable temperatures necessary for biological research or hatching eggs.

5. Common Troubleshooting Tips

Working with PID controllers may present you with some common issues. Here are a few troubleshooting tips:

* Erratic Temperature Readings: Check sensor connections to make sure they are secure and accurate before diagnosing as an irregular reading issue.

* Overshooting or Undershooting: Adjust the PID parameters, specifically its derivative component, in order to address these problems and maximize performance.

* Slow Response Time: Increase proportional gain to make the system more responsive.

6. Conclusion

Programming a PID temperature controller requires knowledge and expertise of its principles as well as precise tuning of parameters. By following the steps outlined herein, precise and stable temperature regulation for applications can be accomplished quickly and effortlessly. For further reference and learning purposes, additional resources and authoritative guides may also prove beneficial.

- What is a PID Controller and How Does It Work: A Comprehensive Guide

- What Does a PID Controller Do? Understanding Its Functionality and Applications