Discover How to Design an Effective Temperature Control System: A Comprehensive Guide

With our in-depth guide, discover key components, design principles and best practices that ensure efficient temperature regulation systems with optimal performance and efficiency.

1. Introduction

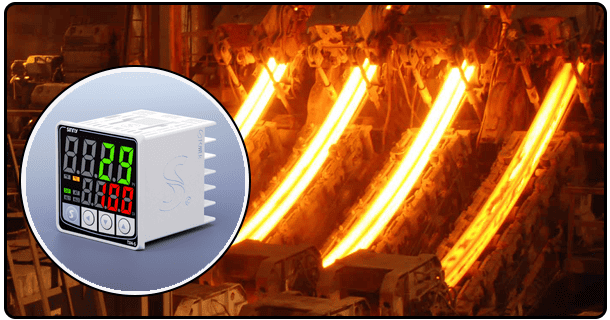

Temperature control systems are integral in several industries, assuring optimal performance, safety, and efficiency. From industrial processes to medical devices, temperature-regulating systems ensure precise temperature conditions are consistent across environments. This article looks into design principles, component selection, integration processes, and maintenance plans for effective temperature-regulation solutions to provide insight into creating reliable yet efficient solutions.

2. Understanding the Basics

Temperature control systems serve a vital function: precisely maintaining an environment's desired setpoint temperature. Key components include sensors, controllers and heating/cooling elements, which play key roles across industrial manufacturing environments and laboratory environments requiring precise temperature regulation. Temperature control systems are essential in applications from medical research labs to industrial manufacturing operations requiring exact control.

Design Principles

Sensor Placement

* Importance of Accurate Sensor Placement:

Proper sensor placement is integral for accurate temperature measurements and control, leading to more precise readings and effective system performance. Erroneous readings or improper system function could occur from incorrect sensor positioning - for instance, placing one too near to heat sources may lead to overheating while placing one too far away can delay responses and slow reaction times.

* Recommended Practices for Different Applications:

In industrial settings, sensors should be located close to heat sources or process areas for accurate readings; when monitoring HVAC systems, they should avoid direct sunlight, drafts, or any source of interference that might give false readings; medical applications require placing sensors accurately reflecting the temperature of the environment being monitored or equipment being tracked.

3. Tuning PID Control

* Explanation of PID Control:

PID (Proportional-Integral-Derivative) control combines three control actions to maintain the desired temperature. Proportional control adjusts the output based on the error, integral control eliminates steady-state error, and derivative control predicts future errors. This combination allows for precise and stable temperature regulation.

* Steps for Tuning PID Controllers:

Tuning requires setting the proportional, integral and derivative gains for effective PID control. Starting with proportional gain adjustment before fine-tuning with integral and derivative gains as necessary based on the system oscillation response, one popular approach is the Ziegler-Nichols tuning method, which adjusts gains on the oscillatory response of the system.

System Response Time

* Factors Affecting Response Time: Response times in systems depend heavily upon their thermal mass, sensor accuracy, and controller speed, and larger thermal masses react slowly. In comparison, smaller thermal masses can react more rapidly compared to changes. Furthermore, sensor accuracy and controller speed are integral to how quickly systems can adapt to temperature variations.

* To Optimize Response Time:

Use high-quality sensors and fast controllers that offer rapid responses and minimise distances between sensors and control elements to boost system responsiveness. Likewise, materials with reduced thermal inertia may help speed things further along.

Insulation

* Insulation's Role in Temperature Control: Insulation helps achieve and maintain desired temperatures by limiting heat transfer through insulation materials or protecting from outside temperature variations, ensuring consistent performance over time. With proper insulation installed and functioning properly, energy efficiency and stable temperature regulation can be ensured, as well as energy savings through efficient usage of energy resources and increased performance from systems protected from external changes in climate conditions.

* Insulation Materials:

Fiberglass, foam, and reflective barriers are common insulation materials. When selecting materials based on application and temperature range considerations (i.e. ceramic fibre/mineral wool for high-temperature applications or polyurethane foam for lower-temperature ones), materials that meet this standard could include fibreglass insulation material; alternatively, polyurethane foam may work best depending on what materials your application requires.

4. Selecting Components

Sensors

* Types of Sensors: Common sensor types include thermocouples, resistance temperature detectors (RTDs), and thermistors. Each has unique benefits that suit different applications; thermocouples offer a wide temperature range and fast response time. RTDs deliver accurate temperatures at high levels, and thermistors offer cost-effective yet sensitive performance.

* Criteria for Selecting Sensors:

When selecting sensors, consider factors like temperature range, accuracy, response time, and environmental conditions. RTDs tend to be preferred because of their accuracy and stability, while thermocouples may offer faster response times for applications requiring quick reaction times.

Controller Types

* Controllers come in various varieties: on-off, proportional, and PID controllers can all provide effective temperature regulation at cost-effectiveness; however on-off controllers can create temperature oscillations due to simple design features, while proportional controllers offer smoother control while PID delivers greater precision and consistency.

* Selecting an Appropriate Controller:

Determine your required precision, response time and complexity before choosing your controller. PID controllers offer optimal accuracy and stability; on-off controllers suffice in less critical applications with cost considerations in mind.

Heating/Cooling Elements

* Various Forms of Heating and Cooling Elements: Heating elements include electric heaters, heat exchangers and infrared heaters, while cooling elements include fans, refrigeration units and thermoelectric coolers - each type has unique benefits suitable for different uses and situations.

* When Selecting Elements:

It is essential to carefully consider heating/cooling capacities, response times and compatibility with control systems when making decisions regarding element selection. Ensure the elements can handle the required temperature range and load conditions - for instance, electric heaters work great when fast heating needs must be fulfilled quickly; at the same time, heat exchangers provide efficient heat transfer solutions.

5. System Integration

Wiring and Connections

* Best Practices for Wiring and Connections

To reduce electrical noise and ensure reliable signal transmission, invest in high-quality cables with shielded conductors to minimise electrical interference. Grounding is critical to maintaining system integrity and preventing interference between sensors and power cables, which helps avoid electromagnetic interference risks! Also, please don't run sensor cables parallel to power cables to ensure the risk of electromagnetic interference.

* Assuring Reliable Connections:

Use secure connectors and regularly inspect connections for signs of wear or damage to ensure reliable operation and accurate readings and system failures. Loose or corroded connections may result in inaccurate readings and system shutdown; regular maintenance and testing of these connections is key to minimise issues and ensure reliable operations.

Software Integration

* Role of Software in Temperature Control: Software plays a vital part in monitoring and controlling temperature systems, providing real-time data analysis, remote monitoring capabilities, and automated adjustments, as well as predictive maintenance alerts and detailed performance reports from advanced solutions.

* Examples of Control Software:

LabVIEW, MATLAB and custom-built apps are popular control software solutions, providing user-friendly interfaces and advanced features for precise temperature regulation. They may integrate seamlessly with other systems or devices for comprehensive temperature management solutions.

6. Testing and Calibration :

* Importance of Testing and Calibration:

Regular temperature control system testing and calibration ensure that it operates accurately and reliably, considering sensor drift or other potential performance-reducing factors. In contrast, regular testing helps identify any issues before they become problematic.

* Methods for Assessing Temperature Control Systems:

Conduct functional tests to confirm that your system responds appropriately to changes in temperature. Use calibration equipment to compare sensor readings against known standards to adjust them appropriately and set proper levels.Documenting test results and calibration data is vital in upholding system accuracy and conformance.

* Calibration Procedures for Sensors and Controllers: When calibrating sensors and controllers, follow manufacturer specifications for calibration procedures. Regular calibration schedules help maintain accuracy by helping avoid deviations over time; calibration should occur under controlled conditions to ensure its precision and repeatability.

Maintenance and Troubleshooting

* Regular Maintenance Practices: Inspect and maintain your system on an ongoing basis to maximise longevity and performance, such as cleaning sensors, checking connections, or verifying heating/cooling elements are working efficiently. Regular inspection and maintenance help avoid unexpected failures by keeping components functioning at peak condition - helping extend their lifetimes as a result!

* Common Issues and Troubleshooting Tips:

Common problems include sensor drift, controller malfunctions and heating/cooling element failures. When troubleshooting these problems, it's essential to isolate them by isolating any obvious faults and consulting system documentation; additionally, keeping a log of maintenance activities may help identify repeat incidents, thus improving system reliability.

Case Studies

* Examples of Effective Temperature Control System Designs:

Case studies provide real-world examples of successful temperature control system implementations. They highlight best practices, challenges faced, and solutions applied. For example, a case study on a pharmaceutical storage facility might detail how precise temperature control ensures the integrity of medications.

* Lessons Learned From Real-World Applications:

Analyzing case studies helps uncover common pitfalls and strategies for successfully implementing and maintaining temperature control systems. So, lessons from such examples may be applied to future designs or implementations of similar projects.

7. Conclusion

Designing an efficient temperature control system involves understanding its basics, choosing suitable components and ensuring proper integration and maintenance. By adhering to best practices and using advanced technologies, you can build reliable temperature controls tailored specifically for your application - becoming ever more precise as technology develops, further enhancing the performance and efficiency of such systems.

- Temperature Control System and Controller: Key Differences

- Expert Guide: Installing Temperature Control Systems for Optimal Performance