How to Calibrate an Inkbird Temperature Controller

Learn how to calibrate your Inkbird temperature controller with our comprehensive guide. Follow step-by-step instructions to ensure accurate temperature readings for home brewing, aquariums, greenhouses, and more.

1. Introduction

Inkbird temperature controllers have long been recognized for their ease of use and reliable operation in applications ranging from homebrewing, aquariums and greenhouses to automotive. To provide accurate temperature readings from these controllers, calibration must occur - this guide demonstrates how you can calibrate an Inkbird controller so your system operates at maximum performance.

2. Understanding Calibration

Calibration involves calibrating temperature controllers against an industry or industry reference standard or baseline to ensure accurate readings from their controls. Calibration should take place regularly because even minor discrepancies in temperature readings can have dramatic ramifications for processes requiring precise temperature regulation.

3. Components Required for Calibration

In order to calibrate an Inkbird temperature controller, the following items will be necessary. Temperature Controller of Inkbird Brand. - this device you are calibrating

Reliable Thermometer:

Use an accurate thermometer as a benchmark against which to compare Inkbird controller temperature settings.

Calibration Tools:

These may include items such as an ice bath and boiling water to produce known temperatures points.

4. Steps for Calibrating an Inkbird Temperature Controller

Establish the Calibration Environment:

Make sure the environment is calm and free from drafts that might compromise temperature readings, gather all tools and components needed, then begin.

Setting Up an Inkbird Controller:

Plug the temperature controller directly into its power source and verify its functionality before placing its temperature sensor where you will conduct calibration.

Comparing Readings With a Reference Thermometer:

To use this step effectively, place both devices into an identical environment, allow both to stabilize, compare their readings, and note any discrepancies or discrepancies that arise between their readings.

Adjusting Calibration Settings:

Access your Inkbird controller's calibration settings through its menu system and make the necessary modifications to address any discrepancies noted during step 3 as soon as you notice them.

Verifying Calibration:

After making adjustments, verify calibration by comparing readings again and making any necessary corrections until readings closely match up. Repeat the process if needed until all readings agree closely.

5. Common Calibration Methods

Ice Bath Method:

Fill a container with equal parts ice and water to create an environment of 0degC. Place both an Inkbird sensor and reference thermometer inside, as well as adjust your controller so its reading matches with what was indicated on your thermometer's readings.

Boiling Water Method:

Bring water to boil at 100degC to create an environment conducive for testing Inkbird sensors and reference thermometers in this boiling environment, immerse both of these into it and adjust your controller so its reading matches up with that on your thermometer.

Utilising a Calibration Device:

Calibration devices can simulate different temperatures to provide known points that help adjust Inkbird controllers accordingly.

6. Troubleshooting Calibration Issues

Temperature Fluctuations:

To correct fluctuations, make sure your sensor is located appropriately and that its environment remains steady, such as by eliminating drafts or heat sources that might alter readings

Sluggish Response Time:

If the controller is responding slowly to temperature changes, check that all sensor placement and condition have been properly addressed, while making any necessary changes to proportional gain as necessary.

Inconsistent Readings:

Make sure that both sensors and reference thermometers are located within their intended environments and have had time to acclimatize before recalibrating if necessary. 4. System Instability: If your system seems unstable, check its Derivative Gain settings and make adjustments as necessary in order to stabilize readings.

7. Calibrated Inkbird Controllers

Calibrated Inkbird temperature controllers can be utilized in several different areas, including home brewing for optimal results and to maintain consistent fermentation temperatures for homebrewing applications. * Home Brewing: Offering consistent fermentation temperatures ensure the best brewing results are realized

Aquariums:

For optimal aquatic life health, maintaining stable temperatures is of utmost importance in aquariums.

Greenhouses:

Greenhouses use temperature regulation to encourage plant growth.

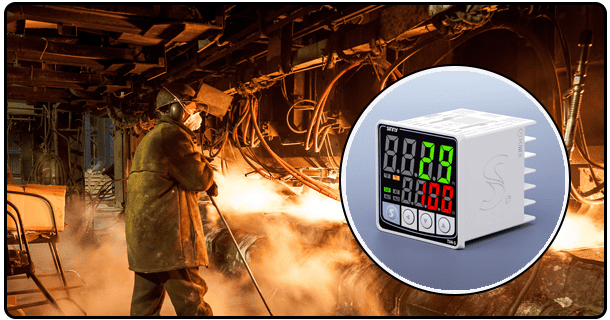

Industrial Processes:

Offering precise temperature regulation during manufacturing and chemical processing operations.

- How to Wire a Digital Temperature Controller: A Step-by-Step Guide

- How to Use a PID Temperature Controller: A Comprehensive Guide