How to Make a PID Controller: Comprehensive Guide for Beginners

Learn how to make a PID controller with this comprehensive guide. Understand the principles of PID control, set up the hardware, write the algorithm, tune the controller, and test your system. Perfect for industrial control systems and various applications.

1.Introduction

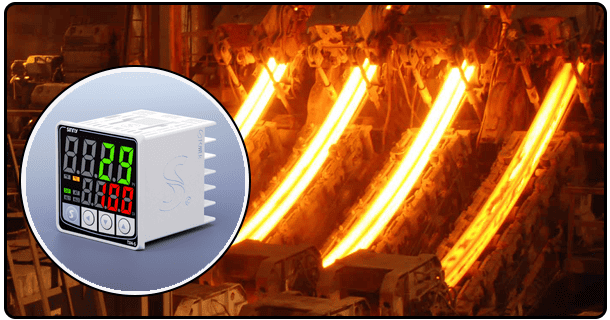

Introduction mes A Proportional-Integral-Derivative (PID) controller is an industrial control loop feedback mechanism. It continuously calculates errors between desired setpoint and measured process variable values and applies correction based on proportional integral and derivative terms to address those discrepancies. PID controllers play an essential role in temperature, motor speed and process controls among other areas of application.

2.Understanding PID Control

PID control involves three distinct parameters, Proportional (P), Integral (I), and Derivative (D). Proportional control produces output values proportional to any current error value while Integral term looks into past error accumulation while Derivative term predicts future errors based on rate of change. A PID controller's mathematical representation can be seen here:

$$ U(t) = K_p, E(t), + K_iint E(t), Dt + K_d de(t)dt where U is the control output and E is error; K is proportional gain and K_d is differential gain respectively.

3.Components Needed

To create a PID controller, the following items will be needed. * A microcontroller such as Arduino may also work;

* Sensors: Sensor types depend upon your application (temperature sensor or rotary encoder for instance).

Actuators: Devices used to regulate processes (for instance motors and heaters).

* Power Supply: Sufficient power source to support both microcontroller and actuator functions.

* Software: Arduino IDE and PID libraries

4.Set Up of Hardware WASP 21

Connect the Actuators: Connect actuators directly to the output pins of your microcontroller using appropriate drivers or relays as necessary.

3. Power Supply: To provide reliable power to both the microcontroller and actuators, ensure both its voltage and current ratings meet requirements for your application.

Write Your PID Algorithm

1. Import Libraries: Make sure all necessary libraries are present in your Arduino sketch.

1. Define Variables: Setup variables to setpoint, input, and output settings.

Attractively setpoint double setpoint input/output.

1.

Initialise PID Object: Create and configure a PID object using its parameters.

PID myPID(&input,&output,&setpoint,Kp, Ki, Kd and DIRECT);

1. On-Set Function (Set Function): When configuring a PID controller in this setting function.

1. Establish the PID control loop using this function.

Void Loop(); input = analogRead(sensorPin); myPID.Compute();

analogWrite(actuatorPin, output); *

5.Tuning a PID Controller

Tuning the PID controller involves adjusting its three parameters of (K_p), (K_i), and (K_d), until desired control performance has been attained. A common approach is Ziegler-Nichols technique; which involves setting (K_i ) and (K_d ) equal zero before increasing (K_p ) until system oscillation begins, before further adjustments to these KPID parameters based on specific formulae are applied.

1. Initial Testing and Debugging

Run the PID Controller. Upload code directly into microcontroller, turn PID control off. 2. Subsequent Steps (Testing and Debugging).

3. Results and Adjust PID Parameters as Needed 3.

Troubleshoot As Needed Troubleshoot Known Issues

Noise in Sensor Readings, Actuator Saturation, and Stability.

6.Applications and Examples

PID controllers are versatile tools used in various real-world situations. For instance, in temperature control systems they are utilized to maintain desired temperatures by adjusting power supplied to heaters; similarly in motor speed regulation PID controls can regulate motor speeds by altering voltage applied directly. Such examples demonstrate PID control's versatility and effectiveness.

7.Conclusion

Establishing a PID controller requires understanding its principles, installing necessary hardware, writing the PID algorithm, tuning your controller and testing its system. By taking these steps carefully and efficiently designing one PID controller can lead to several applications with greater reliability and performance than its alternatives.

- How to Reduce Oscillation in PID Controllers: Comprehensive Guide

- How to Use a PID Temperature Controller: A Step-by-Step Guide