How to Program a PID Temperature Controller: A Comprehensive Guide

Learn how to program a PID temperature controller with this comprehensive guide. Understand PID control principles, wiring, programming, and troubleshooting for precise temperature control.

1. Introduction

A PID (Proportional-Integral-Derivative) controller is a widely employed control loop feedback mechanism in industrial control systems, used for precise temperature regulation across many applications ranging from household appliances to complex industrial processes. In this article we'll show how you can program one yourself, covering basic concepts as well as practical implementation.

2. Understanding PID Control

PID control involves three distinct actions, Proportional, Integral and Derivative. While Proportional controls focus on current errors while Integral accumulates past ones. Derivative predicts future ones based on its propensity to accumulate errors over time. Combined together these components help achieve temperature regulation by adjusting output control output in such a way as to minimize differences between setpoint and actual temperature errors.

3. Components Needed

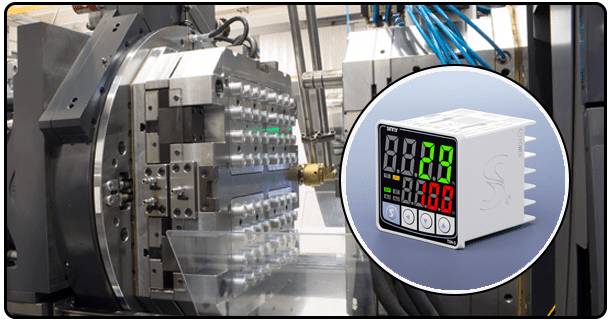

In order to program a PID temperature controller, the following items will be necessary.* PID Controller : The main device responsible for performing its algorithm for control.

Temperature Sensor:

To accurately record and track temperature readings. Usually a thermocouple or RTD are employed.

Heating Element or Cooling Device:

Used to adjust the temperature.

Power Supply:

Used to power controller and other components.

Microcontroller (optional):

For custom setups, an Arduino or similar microcontroller could be useful as part of the solution.

4. Connect the PID Controller

Wiring your PID controller correctly is key to its successful functioning and can be accomplished following these steps:

Connect a Temperature Sensor:

Attach it to its appropriate input terminal on a PID controller.

Wire an Heating/Cooling Element:

Join its output terminals of the controller.

Ultimately, Power Connections:

Make sure all components are connected to an appropriate power source.

Safety Considerations:

For your own protection and to reduce potential electrical faults, include fuses or circuit breakers as a safeguard.

5. Programming the PID Controller

Programming the PID Controller Programming a PID controller entails setting the desired temperature (setpoint), configuring PID parameters, and testing out various scenarios until reaching optimal performance. Here's how it should go:

Select Your Desired Temperature:

To input the target temperature into the controller.

Customise PID Parameters:

Adjust Proportional (P), Integral (I), and Derivative (D) values accordingly - many controllers offer auto-tuning features to make this step simpler

When complete, calibrating will begin:

Once again inputting desired target temperatures is the first step; once adjusted PID Parameters can then be customized further by simply moving sliders within their PID controls; this time step should only needing adjustment manually once.

Configure PID Parameters can then be configured; this step usually needs adjusting Proportional, Integral (I), and Derivative (D).

Configure PID Parameters for proper PID control is then tuned by moving sliders between Proportional, Integral, Derivative values can then easily adjusted while many controllers offer auto-tune features to simplify this step; once adjusted auto tuning features to expedite this step.

Adjust P, Integral Integral Derivative values should also be tuned with regard to Auto Tuning features auto tune Auto Tuning features to help with regards tuning this step as part. To final step will auto tune automatically tuning features can further simplify tuning steps while some have auto tuning features which makes fine-tuning features to automating process

Manual Tuning:

In lieu of autotuning, manually adjust PID parameters by trial-and-error until stable control can be achieved.

After programming is complete, it is imperative that the system be tested and calibrated: this step may involve both manual testing and computerized calibration systems.

Initial Testing:

Run and observe temperature control performance.

Adjust PID Parameters:

Tweak PID settings to minimize overshoot and oscillation.

Monitor and Log Data:

Make adjustments as necessary through data logging by tracking temperature changes over time, tracking changes via temperature loggers.

Modern PID controllers feature advanced features designed to improve functionality:

integrating with Other Systems:

When connected to PLCs or SCADA systems for centralized control.

Remote Monitoring and Adjustment:

Utilize network capabilities for remote monitoring and controlling of the controller. 3. integration With Other Systems

Safety Features:

Implement alarms and automatic shutdowns to guard against overheating or other risks.

Common Issues and Solutions with PID Controllers and their solutions:

Oscillations in Temperature Regulation (PID parameters). 2 Slow Response, increase Proportional Gain or decrease Integral Time and/or Proportional gain or Integral time as necessary (Proportional gain reduction is better). 3. System Instability, check wiring problems or sensor malfunctions as issues.

6. Conclusion

Programming a PID temperature controller involves understanding the PID control principles, selecting the right components, proper wiring, and fine-tuning the PID parameters. With careful setup and calibration, you can achieve precise temperature control for various applications. Future improvements may include integrating more advanced features and enhancing system reliability.

- how to repair temperature controller

- How to Wire a Digital Temperature Controller: A Step-by-Step Guide