How to Understand PID in PID controller: Comprehensive Guide

This comprehensive guide will help you understand the PID acronym in PID controls. Discover the roles of proportional, derivative, integral and other components in order to achieve precise control.

1. Introduction

This article provides an in-depth explanation of PID Controllers, their parts, and their application.

2. PID Definition

and each plays a vital role in the process.

3. Component of Proportional (P).

It is the proportional component P that corrects the difference between the setpoint desired and the process variable. This is done by applying a proportional correction to the error. Corrections are proportional to the size of the error. The immediate reaction helps reduce errors quickly.

In a system for temperature control, proportional control can increase power in the heater if actual temperature falls below the setpoint. This will reduce the difference between the two temperatures. Although proportional controls are effective, they can cause a steady state error in which the variable process never reaches its setpoint.

4. Integral (I) Component

Integral component I addresses steady state error issues by adding up the errors over time, and then applying corrections based on that total error. The integral component (I) corrects even minor errors over time.

Integral control, in the example of temperature control, will add power to heaters until they reach the desired temperature, eliminating steady-state errors. Over-integral action may lead to instability and overshooting.

5. Derivative (D) Component

By analyzing how fast the error is changing, the derivative component D can predict future errors. The derivative component (D) applies a corrective action based on how fast the error changes. It helps improve stability by damping the oscillations of the system and reducing the overshoot.

The derivative control in a temperature control system will reduce the power going to the heater when the temperature is approaching the presetpoint. This prevents overshooting and improves stability. Too much derivative control can cause excessive damping or slow response time.

6. Combine P, I and D Components

The PID controller is a combination of the integral and derivative components that allows for precise control. The proportional part provides an immediate correction. The integral component removes errors at steady state, while the derivative improves stability. A PID controller's performance can be optimized by carefully adjusting the gains for these components.

In a system for temperature control, for example, a PID controller will adjust the power of the heater by combining the actions of integral, proportional and derivative components. The actual temperature will quickly reach the desired setpoint, without oscillation or overshooting.

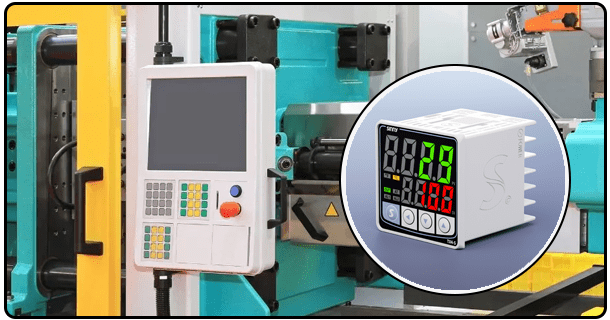

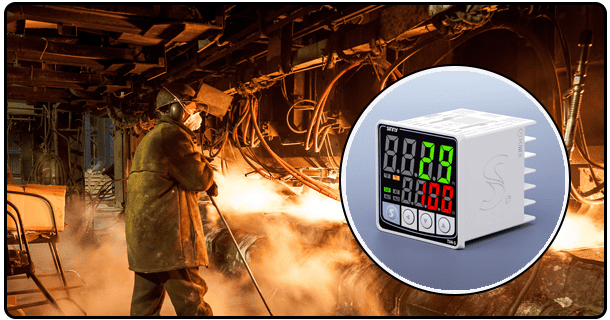

7. Application of PID controllers

The PID controller is used for a variety of industries and applications including

Production PID controllers are used to regulate manufacturing processes, such as pressure, temperature and flow.

HVAC System Controls the temperature and humidity of heating, ventilation and air-conditioning systems.

Automotive : In engine control systems, PID controllers regulate fuel injection and emissions.

Robotics : These provide control over motor position and speed in robotic systems.

Process control: In the chemical, pharmaceutical and food industries, PID controllers maintain precise control over critical parameters.

Anyone who works with PID devices must understand what the PID acronym stands for. Each of the components, such as proportional, derivative, and integral, plays a vital role in controlling a system precisely. A PID controller provides optimal performance by carefully tuning these gains. This increases the accuracy and efficiency of the control system.

- What is PID control? Comprehensive Guide to Proportional-Integral-Derivative Control

- The Complete Guide to Setting Up PID Temperature Controls