PID Temperature Controllers: Essential Features and Specifications

Check out our guide of PID temperature controllers, covering key features, specifications and industry applications. Discover how to select an ideal controller for precise temperature regulation as well as advanced functions designed for enhanced performance.

1. Overview of PID Controllers

PID controllers are essential tools used to precisely regulate temperature in manufacturing, chemical processing and food production processes that demand precise temperature management. By continuously adjusting output according to any differences between setpoint and actual temperatures, they help keep temperatures within tolerance while remaining comfortable for employees and customers.

2. Key Features of PID Temperature Controllers

Proportional, Integral and Derivative Control:

Proportional Control (P): This feature adjusts output proportionally to any errors; with higher proportional gain allowing a stronger response to errors.

Integral Control (I): Accumulating past errors helps eliminate steady-state error for improved long-term accuracy and maintain precision over time.

Derivative Control (D): Derivative control uses rate changes as input data to predict future errors, helping reduce overshoot and enhance stability.

Auto-Tuning Functionality:

Autotuning functionality utilizes automated tuning capability that predicts and corrects for future errors based on changes over time, helping avoid unexpected overshoot and restore balance to systems quickly and accurately.

Auto-Tuning automates the process of setting optimal PID parameters, making set up easier and ensuring efficient performance by those without extensive technical knowledge.

Multiple Input/Output Options:

This feature makes setting optimal parameters much simpler while streamlining controller setup for effective controller performance.

PID controllers usually support various input types such as thermocouples, RTDs (Resistance Temperature Detectors), voltage, current or relay inputs; they also offer relay, voltage pulse or current output options to give users maximum flexibility in meeting varying applications.

Display and Interface:

A clear and user-friendly display is critical when monitoring and adjusting settings. Digital displays, touch screens, and intuitive user interfaces help make their use simple while providing real-time monitoring capabilities and configuration assistance.

Communication Protocols:

Modern PID controllers often include communication protocols like Modbus, Profibus or Ethernet for easier integration into other control systems and remote monitoring and control.

3. Safety Features:

Safety should always be the top priority in any control system, with essential safety features like alarm functions, fail-safe modes and overtemperature protection to make sure everything

Detailed Specifications can be found HERE operates within safe limits while safeguarding equipment and processes.

Temperature Range and Accuracy:

Temperature range defines the parameters within which an effective controller operates, with accuracy being crucial in order to keep setpoints at their target temperatures. High precision controllers offer improved performance for sensitive applications.

Control Modes

PID controllers offer various control modes, including ON/OFF, proportional, and PID modes, depending upon application needs and desired precision requirements. Choosing an ideal mode depends upon both considerations relating to application needs as well as desired control precision levels.

Power Supply and Consumption:

Understanding the power requirements and consumption of PID controllers is vital in order to ensure compatibility with your system and lower energy costs. Most controllers use standard AC or DC power supplies.

Environmental Conditions:

Controllers must meet the environmental demands of their operating environment, taking into account factors like temperature range, humidity tolerance and resistance to dust and water as essential specifications.

4. Mounting and Installation:

Installation and mounting considerations should always be top priorities; controllers can be placed panel-mount, DIN rail-mount or wall mount depending upon application needs and available space.

Selecting the Appropriate PID Controller

Evaluating Application Requirements:

Beginning by understanding your application requirements - including temperature range, accuracy and control modes - will enable you to narrow down options that meet them more closely.

Comparing Features and Specifications:

Compare Features and Specifications: Compare PID controller models that feature your desired input/output options, communication protocols and safety features before choosing one to buy.

Consider Brand Reputation and Support:

When making your selection consider brand reputation and support when possible

Select controllers from reliable manufacturers known for quality and dependability. Keep customer support, warranty coverage and service options in mind as part of the evaluation.

Assess Cost vs Value

As cost remains an essential consideration when purchasing controllers, keep the value provided in mind as well. A slightly higher initial investment could justify itself through superior performance, durability and added features that provide real advantages to industry applications.

I

5. ndustry Applications

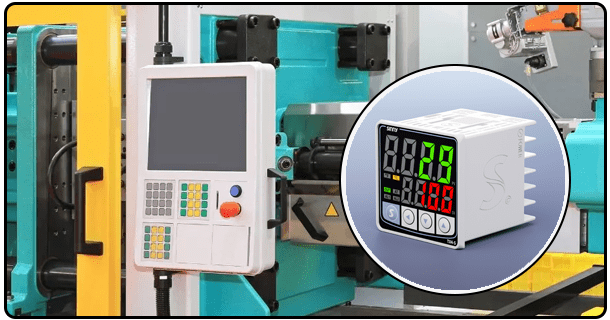

Manufacturing:

In manufacturing environments, PID controllers are used to ensure consistent temperatures during processes like plastic extrusion, metal forging and welding - critical steps which ensure product quality and consistency.

Chemical Processing:

Chemical processes require precise temperature regulation in order to maximize reaction efficiency and safety, making PID controllers invaluable in maintaining optimal conditions without risk of deviation that could endanger workers or put themselves or the public at risk.

Food Production:

In food production, keeping temperatures consistent is of critical importance for safety and quality of production. PID controllers regulate temperatures during cooking, pasteurization and refrigeration processes to comply with safety standards.

HVAC Systems:

PID controllers are widely utilized in HVAC systems to regulate temperature and provide comfort, while maintaining energy efficiency in residential, commercial, and industrial settings.

Their advanced features help provide consistent indoor climates while increasing energy savings.

Adaptive Control:

PID controllers capable of dynamic adaptive control can adjust their parameters real-time according to changes in process conditions or loads, providing continuous performance regardless of loads or changes in conditions. These features make Adaptive PIDs especially helpful in applications involving varied loads or conditions as it ensures consistent results over time.

Self-tuning algorithms:

offer a great advantage in complex systems where manual adjustments may prove to be daunting - self-tuning algorithms automatically optimize PID parameters, making manual tuning unnecessary. This advanced feature proves particularly valuable.

Integrating With IoT (Internet of Things):

Integrating PID controllers with other smart devices and systems through IoT enables remote monitoring, data analysis, predictive maintenance capabilities as well as improved overall system efficiency thereby improving overall system efficiency.

Maintenance & Troubleshooting Services Providers.

Regular Calibration:

To keep a PID controller accurate over time, regular calibration must take place according to manufacturer recommendations on calibration periods and procedures.

Monitoring Performance:

Begin monitoring the controller regularly in order to identify any discrepancies or potential problems early. Take advantage of its display and communication features for key parameters and system status monitoring.

Troubleshooting Common Issues:

Be familiar with common issues such as sensor faults, wiring issues and parameter setting errors. A troubleshooting guide and access to technical support will enable faster resolution.

6. Conclusion

Summary of Key Points:

PID temperature controllers provide precise temperature regulation across various industries. Understanding their features, specifications and advanced functions is paramount to selecting an apt controller for your specific requirements.

Stay abreast of the newest advances in PID technology and industry best practices to stay at the cutting-edge and maximize temperature control systems. Through ongoing learning and professional development, make informed decisions for optimal temperature control systems and keep pace with technological progress.

- How PID Temperature Controllers Reduce Waste and Save Costs

- How to Fine-Tune Your PID Temperature Controller Settings