The Complete Guide to Controlling a PID controller

Our comprehensive guide will teach you how to use a PID control. Explore the common methods of control to optimize system performance.

1. Introduction

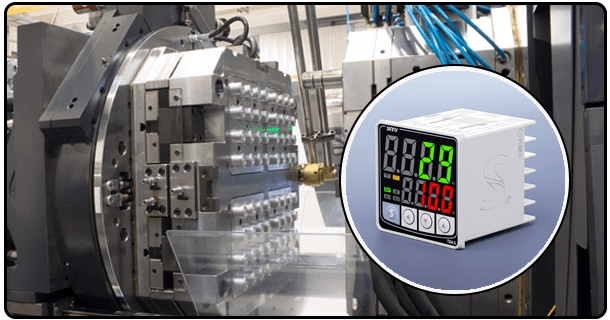

Proportional-Integral-Derivative (PID) controllers are a cornerstone in the field of control systems engineering. They are used in a wide range of applications including HVAC, industrial automation and robotics to achieve the desired results. Controlling PID controllers plays a vital role in optimizing performance and maintaining system stability. The article will explain the finer points of PID control, including the integral, proportional and derivative functions, as well as provide a guide to effective methods of control.

2. Understanding PID Control

Proportional (P).

This component is often abbreviated "P" and is responsible for generating an output directly proportional with the error value. The proportional gain parameter (Kp), which determines how strong the proportional response is, is crucial. The system will become more responsive by increasing the gain. Setting the gain proportionally too high may lead to oscillations and instability.

Integral I

Integral component (I) is used to remove any steady-state errors that remain after proportional control. Integral gain (Ki), which adjusts cumulative errors over time to bring the output of the system closer to desired setpoint, is a way for the integral component. An excessive integral gain, however, can make the system sluggish or prone to oscillations.

Derivative (D)

This derivative component (abbreviated "D") predicts future error behavior based on the rate of its change. The derivative gain, abbreviated as Kd, helps dampen oscillations to enhance system stability. The derivative component is sensitive to noise, and can lead to unsteady behavior when not properly tuned.

3. Controlling a PID controller

Initial Configuration

Verify the mechanical soundness of the system Before starting the control, you must ensure that there are no mechanical problems such as worn out components or loose connections.

Initialize PID to zero: Start the control by setting Kp, Ki and Kd to zero. It provides a base for control of each component.

4. Controlling Proportional Gains (P)

Increase the P value until the output of the system begins to oscillate : Gradually raise the proportional gain, Kp until it starts to oscillate. The system is now responding to the proportional control.

Reducing P to half of the value which caused the oscillation Once the system begins to oscillate, reduce the gain proportional to the half value. It helps to achieve the right balance between stability and responsiveness.

Controlling Integral Gain I

Increase I gradually to remove steady-state errors: Gradually raise the integral gain to correct any steady-state errors that remain. It is important to get the output of the system closer to its desired setpoint, without creating excessive oscillations.

Monitor the response of the system and make adjustments as necessary: Constantly monitor the response of the system to the changes in integral gain. Adjust the system to get desired results while avoiding instabilities.

5. Controlling Derivative Gains (D)

Increase D slowly to dampen oscillations : Start by increasing derivative gain (Kd). This will reduce oscillations, and increase system stability. This derivative component can be used to counteract and predict rapid errors changes.

Adjust D until desired stability is achieved . Continue to adjust the derivative gain, and the system will exhibit a stable behavior. Set the derivative gain to an appropriate level. Too high a setting can cause erratic behavior and increase noise.

6. Common Control Techniques

Ziegler-Nichols Method

Ziegler-Nichols is an established technique to control PID controllers. These steps are:

Zero the gains integral and derivative (Ki,Kd).

The system will oscillate for a sustained period of time when the gain is increased to the maximum (Ku).

Calculate the PID gain using the Ziegler and Nichols formulas.

Cohen Coon Method

This method, which is based on the Cohen-Coon approach, can be used to control PID controllers in particular for processes that have significant dead time. These steps are:

Open-loop testing is the best way to find out what process reaction curve you have.

Calculate process parameters such as time constants and dead times.

Use the Cohen-Coon tuning equations to find the best PID gain.

7. Test and Error

Iteratively adjust the PID gain based on performance of system. It is a practical approach for complex systems that are difficult to model mathematically. To find the optimal PID setting, start with small changes and monitor the response of the system.

Effective Tips to Control

Make small changes: To avoid drastic system effects, make incremental adjustments to PID gains.

Give time between changes: Allow the system time to react to any adjustments before continuing.

Simulators: Use PID simulations to understand and practice the effects of PID gain.

It is important to control a PID correctly in order to achieve optimal performance and system stability. Understanding the function of integral, derivative, and proportional components, as well as following systematic methods for control, will allow you to control PIDs effectively. The system will be more reliable and efficient if the PID gains are continuously monitored and adjusted.

- The Complete Guide to PID Control Loop Tuning

- How to make a PID controller in Simulink : a comprehensive guide