Understanding PID in Temperature Controllers: Proportional, Integral, Derivative

Learn what PID stands for in temperature controllers and how Proportional, Integral, and Derivative components work together to maintain precise temperature control in various industries.

1. Introduction

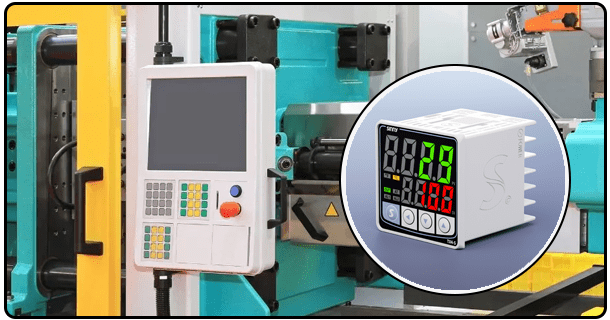

Temperature controllers have become an indispensable asset across industries for managing precise temperatures and overseeing processes that rely on stability - such as manufacturing, food processing and chemical production. A PID temperature controller has quickly become one of the go-to devices when controlling precise temps; but what exactly are its functions and why so many rely on this device when managing specific temps?

2. What is PID?

What Does PID (Proportional, Integral and Derivative) Controller Mean PID stands for Proportional, Integral and Derivative controllers which work to keep temperatures within their desired settings at their target settings - each term playing its part for this result. By understanding them more thoroughly will give us further insight into the function of these PID controllers.

3. Components of PID Control System

Proportional Control (P)

Proportional control is the first component of PID. It works by adjusting output in proportion to error; that is, any difference between desired setpoint and actual temperature that leads to too low of an environment temperature. If too little heat enters an environment, proportional control increases output to bring temperature back up. As error grows larger so does output adjustment - though ultimately this method only helps minimize errors - rather than eliminate them entirely.

Integral Control (I)

Integral control addresses the limitations of proportional control by accounting for past errors as they accumulate over time and correcting even small, persistent ones. Its integrative nature ensures even small inaccuracies can be corrected over time - an invaluable feature when trying to achieve steady-state temperatures where temperatures may often drift off by small margins.

Derivative Control (D)

Derivative control predicts future errors based on their rate of change, applying corrective measures preemptively before an error arises and dampening oscillations while strengthening system stability.

4. How PID Controllers Operate

PID controllers utilize a feedback loop mechanism. By measuring actual temperature against desired setpoint and calculating any differences, PID controllers adjust output using proportional, integral, and derivative components in real time to keep temperatures as close to setpoint as possible. This real-time adjustment ensures optimal temperatures remain close.

Example of PID controller usage in heating: when temperature falls below its setpoint, PID increases power. Once temperature nears setpoint, however, power reduction occurs so as to avoid overshooting; thus ensuring stable temperatures at all times. This dynamic adjustment ensures stable conditions.

5. Benefits of PID Controllers

PID controllers boast numerous advantages that make them popular choices across numerous applications:

Accuracy and Stability:

PID controllers offer accurate temperature regulation that keeps temperatures steady near their setpoints.

Efficiency:

PID controllers optimize energy usage to minimize waste while improving overall efficiency. They continually adjust output settings to maintain maximum output efficiency and thus enhance productivity and decrease costs.

Versatility:

PID controllers have become ubiquitous across industries ranging from manufacturing and food processing, where precise temperature regulation is of vital importance.

Types of PID Controllers

Standalone PID Controllers These standalone temperature controllers were specifically created for temperature regulation applications where an easy yet dependable solution is necessary. Installation and usage are made straightforward.

Integrating PID Controllers and Programmable Logic Controllers (PLCs). In more complex systems, PID controllers may be combined with Programmable Logic Controllers (PLCs) for advanced control strategies and improved coordination across processes. Such integration makes these PID controllers ideal for industrial applications where multiple parameters need to be controlled simultaneously.

6. Integrated PID Controllers with PLCs

Locating an Appropriate PID Controller on Multiple Considerations Jayne Lakner provides some advice for selecting an ideal PID controller:

Choosing the Right PID Controller

Selecting the right PID controller depends on several factors:

Application Requirements:

Carefully consider your specific needs regarding temperature range and accuracy when making decisions related to applications, for instance.

System Complexity:

For simpler applications, an independent PID controller might suffice. However, more intricate systems might necessitate integrated solutions using PLCs instead.

Budget:

When selecting your controller, ensure it fits within your budget while fulfilling all performance specifications.

7. Conclusion

PID controllers are essential tools in maintaining precise temperature regulation across industries. By learning their components and working principles, one can better appreciate their significance and benefits. As technology develops further, so too do PID controllers - becoming even more accurate and effective as time goes on.

- How to Wire a Temperature Controller: A Comprehensive Guide

- What is a PID Temperature Controller? Comprehensive Guide