Universal Digital PID Programmable Temperature Controller | Precision

Learn about the benefits, features and applications of Universal Digital PID Programable Temperature Controllers. Find out how these controllers ensure accurate and reliable temperature controls across industries.

1. Introduction

The temperature control is a crucial part of many industries.

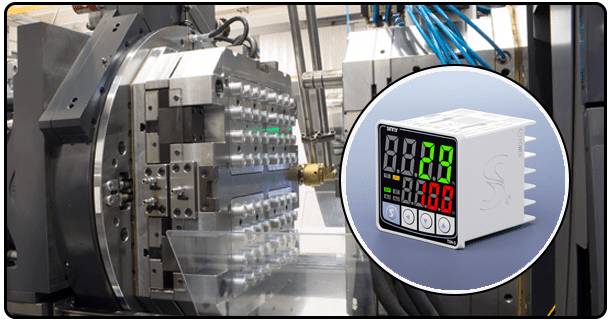

2. PID temperature controller?

These controllers regulate temperature accurately and precisely by balancing integral, proportional and derivative components.

The digital PID controller offers many advantages over analog versions, including enhanced accuracy, programability and seamless integration with automated systems. These controllers are used widely in industrial machines and laboratory equipment where temperature regulation is important.

Programability: The user can customize the settings easily to suit their specific needs, including ramp rates, control modes, and setpoint profiles.

Self Tuning Capabilities Many models have an automatic tuning function that optimizes PID parameters, without the need for manual intervention. This ensures optimal performance.

Alarms: Built in alarms warn operators when deviations occur from the setpoints. This allows for quick corrective actions.

Communications Interfaces: Features such as RS485 compatibility and MODBUS support remote monitoring and controlling.

<

3. Application

The use of universal digital PID temperature controllers is widespread across many industries.

Production: Ensure consistent temperatures during processes such as injection molding, heating treatment, and extrusion.

Food processing: Maintaining exact temperatures for baking, pasteurization and fermentation.

HVAC System: Controlling temperatures for heating, ventilation and air-conditioning systems.

Scientific Research Controlling temperature in experiment, incubators and laboratory ovens.

Kilns & Furnaces : High-temperature stability in ceramics & metallurgical processing.

The controllers can be used in situations where accuracy and reliability are directly related to product quality or process efficiency.

4. Benefits

The benefits of universal digital PID controls are numerous:

Reliability and Precision: The ability to maintain a stable temperature reduces errors, and improves the quality of products.

Energy Efficient: The optimal temperature control reduces energy usage, leading to cost savings.

Flexibility : They are highly flexible due to their programmability.

Integration Made Easy: Compatible with current communication protocols, integration of automated systems is made easier.

How to choose the right controller

When selecting the best PID controller, it is important to consider several factors.

Type of Input: Check compatibility for your sensor choice (e.g. thermocouple or RTD).

Type of output: Select whether or not you require relays, voltage or current outputs.

Accuracy Choose a model with the precision required for your application.

Programability: Search for controllers with the ability to customize settings according to specific requirements.

Support and Brand Reputation Choose a manufacturer with a good reputation and who provides dependable customer service and documentation.

Compare popular models of reputable brands to make an informed choice.

5. Tips for Installation and Maintenance

For your PID to perform well, it is important that you install and maintain the controller properly. These are some helpful tips.

Adhere To Manufacturer's Guidelines: Follow the instructions in the manual for installation.

Regular calibration: It is important to calibrate and check the controller periodically in order to ensure accuracy.

Check Connections : Verify that the wiring connections and sensors are in good condition and not damaged.

Routine Inspection: Check for wear and malfunctions.

6. Future trends in PID controllers

Emerging technologies such as IoT, AI and IoT are shaping the evolution of PID controls. Future trends will include:

Intelligent Integration: IoT enabled controllers allow for real-time remote monitoring and control.

AI Driven Algorithms : AI algorithms that are more advanced will improve performance, adaptability and self-tuning.

Miniaturization : Compact controllers with smaller sizes will be used in applications that have limited space.

Eco Friendly Designs: Models that are energy-efficient and environmentally friendly will be popular.

The PID controllers are becoming more versatile and useful in the industrial and scientific fields.

Universal Digital PID Programable Temperature Controls offer unrivaled precision, versatility and efficiency. They are a popular choice in many industries because of their ability to integrate into automated systems and adapt to different applications. These controllers are expected to play a greater role as technology advances, allowing them to optimize processes and ensure quality.

Learn about the benefits, features and applications of Universal Digital PID Programable Temperature Controllers. Find out how these controllers ensure accurate and reliable temperature controls across industries.

- The tuning of PID temperature controllers: Methods and Applications for Precision Control

- typical pid settings for temperature control