What Are The Types Of Temperature Controllers?

Explore various kinds of temperature controllers (On/Off, Proportional and PID), used for precise temperature regulation within industrial processes.

Temperature control is an indispensable element of many industrial processes, ensuring optimal product quality, safety, and efficiency at every turn. Temperature management plays a central role here. Temperature controllers are devices used to manage temperatures within their desired range—the type used can significantly impact their stability.

In this article, we explore different kinds of temperature controllers along with their applications.

1. On/Off Controllers

One of the simplest temperature controllers, on-off controllers are ideal for managing temperatures in any process. When temperatures fall below the setpoint, they activate heating or cooling devices; once temperatures exceed setpoint levels, they turn them off. There is no in-between state; either full power is given out or none at all is received from them.

Advantages:

Simplicity: These systems are easy to comprehend and operate.

Cost-Effectiveness: On/off controllers tend to be less costly than more complex controllers.

Durability: With reduced cycling operations, wear-and-tear on heating or cooling equipment is decreased significantly, prolonging its useful lifespan and keeping energy costs to a minimum.

Disadvantages:

Overshoot: Inertial effects may cause an overshoot of setpoint temperatures due to thermal inertia in the system.

Not Suited for Precise Temperature Control: These thermometers may not provide precise temperature regulation.

2. Proportional Controllers

Proportional controllers offer an advanced solution for temperature regulation. In contrast with On/Off controllers, proportional controllers reduce power to heaters or coolers as temperatures approach their setpoint temperature; this is accomplished through creating a proportional band around this setpoint where output modulation prevents overshooting its target target value.

Advantages:

Reduced Overshoot: Proportional controllers have the power to reduce overshoot by modulating output, thus speeding up temperature stabilization more rapidly and mitigating any overshoot issues.

Ideal for Sensitive Processes: They offer more precise temperature regulation.

Disadvantages:

Complexity: Proportional controllers tend to be more involved and complex than On/Off controllers.

Cost: These programs tend to be more costly.

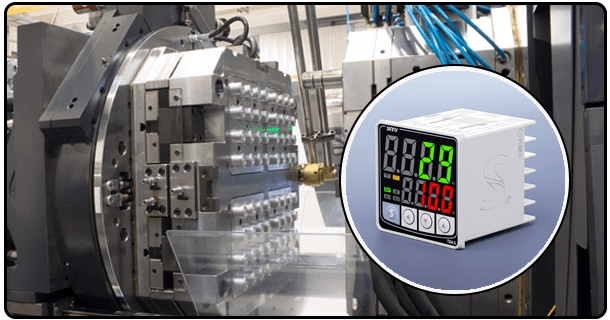

PID Controllers

PID temperature controllers are among the most sophisticated models available today. Their design incorporates Proportional, Integral and Derivative calculations in order to keep temperatures consistent based on current deviation and past deviation accumulation and foresee future deviation prediction. The proportional component depends on current deviation, whereas the integral component accumulates past deviations, and the derivative predicts potential future ones.

Advantages:

Precision: PID controllers offer highly precise temperature regulation.

Quick Response Time: They have the capability of quickly responding to changes in process temperatures.

Adaptability: PID controllers offer great versatility by being tailored specifically to each process's dynamics.

3. Disadvantages:

Complexity: These controllers are one of the more difficult types available today.

Tuning Required: Proper Tuning of PID Parameters Is Essential: Proper tuning of the PID parameters is vital to optimal performance.

4. temperature controller

Application of Temperature Controllers

The selection of a temperature controller largely depends upon the nature and specific needs of the process that needs to be managed. On/Off controllers tend to work best in systems in which precise control over temperatures is not as essential, like heating/cooling applications in buildings; proportional controllers work better where rate changes can occur slowly with potentially hazardous overshoot, such as ovens or environmental chambers; PID controllers offer tight temperature regulation needed in chemical reactions or semiconductor production;