Why Use PID Temperature Controls? Key Features, Benefits and Applications

Better Product Quality For industries like food processing or pharmaceuticals, it is important to maintain a constant temperature. The PID controllers minimize variations, leading to superior results.

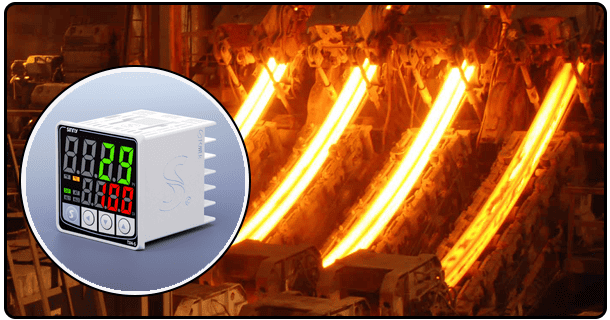

Versatility : PID controllers are used for a wide range of applications from HVAC systems to medical devices, showing their versatility and effectiveness.

Medical and Pharmaceutical : These controllers can be used to control laboratory equipment, incubators and pharmaceutical production. They maintain the precise temperatures required by sensitive processes.

HVAC System PID Controllers are essential in HVAC systems. They ensure temperature regulation and comfort.

The versatility and importance PID controllers play in today's systems is demonstrated by these applications.

1. PID controllers: How they Work

It is important to understand the three main components of PID controls in order to fully appreciate their effectiveness.

Proportional (P): This element provides an immediate response for the difference between setpoint and process variable. The greater the error, then the more powerful the response.

Integral (I): The component that accumulates previous errors, over time. This ensures any remaining discrepancies will be corrected.

Derivative: The derivative component is able to predict future errors by analyzing the rate of changes. This allows the system the ability to combat trends which could cause instability.

Combining these three steps allows PID controllers achieve precision and stability that is unmatched. In a brewery for example, PID controls ensure that the fermentation temperature remains within a small range. This leads to consistent quality of product.

2. How to Set Up and Tune a PID Thermostat Controller

The benefits of PID are obvious, but to achieve optimal performance you need the right setup and tuning.

Install: Make sure that the sensors and controller are correctly positioned, and connected securely.

Configuration : Enter essential parameters such as desired setpoints and control limits into the controller software.

Tuning Use the Ziegler Nicholls method or trial and error to find the optimal proportional, integral and derivative gains.

Suboptimal performance can be caused by challenges such as inaccurate sensor readings, or tuning issues. To maintain system efficiency and stability, regular monitoring and adjustment is essential.

3. The conclusion of the article is:

PID temperature controls are essential tools for modern temperature regulation. They are the first choice for many industries because of their precision, adaptability, and stability. Understanding their benefits and features will allow users to fully utilize the PID controllers' potential for improving efficiency and quality. If you're optimizing your home HVAC or managing an industrial system, investing in PID controllers can have significant benefits.

Discover why PID temperature regulators are the best choice in temperature regulation. Discover their benefits and applications across industries.

- The Comprehensive guide to temperature PID controllers and microcontroller integration

- Understanding PID Temperature Controllers