A comprehensive guide to the implementation of a PID controller

This comprehensive guide will teach you how to set up a PID Controller.

Understanding the design and tuning techniques for optimal performance is important in various applications.

2. Understanding PID Control

The PID feedback control system is popular because it combines three components: proportional, integral, and derivative. The PID control system is versatile because each component has its own unique contribution to the overall action.

Proportional control: The component that adjusts output in proportion to error (the difference between desired setpoint and actual process variables) is . The controller's responsiveness is determined by the proportional gain, KpK_p.

Integral control: This component adds up the errors over time and corrects any steady state or persistent errors. Integral gain (KiK_i), which is based on cumulative error, influences corrections.

Control Derivative: By considering the rate of error change, the derivative component can predict the trend in the future. The derivative gain KdK_d helps dampen the system response and reduce overshoots and oscillations.

The PID equation can be expressed mathematically as follows: $$ U(t), = K_i + K_iint e (t)dt, + K_dfracddt e (t)dt$$

The error is e(t).

3. What are the components and tools needed?

You will need the following tools and components to implement a PID Controller:

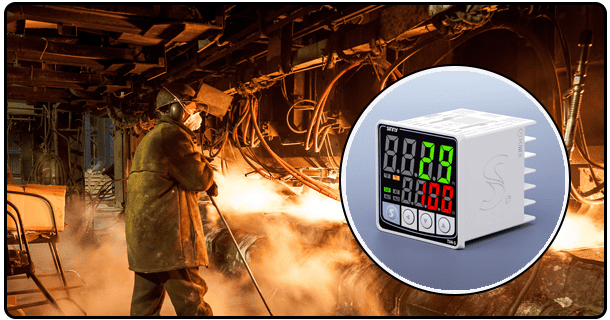

Hardware/Software PID Controller: Includes commercial PID controllers, or custom-built PLCs and microcontrollers.

Sensors Accurate sensors are necessary for monitoring variables like temperature, pressure or position.

Activators: Activators such as motors, heaters or valves perform the desired control action based on controller output.

Microcontroller/PLC To process sensor data, and to implement the PID algorithms, a microcontroller/PLC is required.

4. The Step-byStep Method

Configuring the System

Start by defining your setpoints and variables for the application. Choose sensors and actuators that are suitable for your system. The controller performance is dependent on the accuracy and reliability of the data provided by the sensors.

2. Design of the PID controller

Calculating the integral and derivative gains is a part of designing a PID. The gains are what determines the stability and responsiveness of the controller. Gains can be calculated by using different methods such as Ziegler Nichols or software like MATLAB.

3. Tuning the PID controller

The tuning process is crucial to achieving maximum performance. Ziegler Nichols is one of many methods that can be used for tuning PID gains. The Ziegler-Nichols method is a common way to tune PID gains. It involves adjusting initial gains, causing oscillations and then fine tuning the values.

Considerations for tuning are:

Preventing the Derivative Kick: Make sure the derivative component doesn't cause sudden changes to the output control.

Clamping Integrator: Limiting the integral component in order to avoid excessive accumulation of errors.

4.4. Testing and Validation

To observe the performance of the controller, simulate it in a controlled setting. Validate the controller with real-world data in order to verify that it meets desired specifications. Test the controller using different scenarios.

5. Example of Practical Use

PID implementation in Arduino You can use Arduino to implement PID controls for temperature control applications. Arduino's PID library makes it easy to set the output and define the desired value.

PID Controllers in Industrial Automation: PID controllers are used in industrial automation to regulate pressure in pipes. PID controllers can be implemented using PLCs to ensure precise control, and seamless integration into existing automation systems.

6. The conclusion of the article is:

To achieve the best performance, a PID control system requires an in-depth understanding of all its parts and careful tuning. PID controllers, when used correctly, can improve the precision and efficiency of many automated processes. In the future, it may be necessary to explore advanced control strategies such as model-predictive control and adaptive PID controllers.