How to tune a PID temperature controller: A Step by Step guide

This comprehensive guide will teach you how to fine-tune a PID controller. Learn about the challenges and methods to improve temperature control.

1. The following is a brief introduction to the topic:

The guide explains how to fine-tune a PID controller. These steps will allow users to optimize their controllers' performance and ensure reliable temperature regulation.

2. Understanding PID Parameters

A PID controller is effective because of its three main components: proportional (P), integral (I), or derivative (D). These components each play a role in the regulation of temperature:

Proportional (P). The proportional component is a response to the temperature difference between setpoint and actual. Higher proportional gains increase responsiveness, but can also lead to overshoot or instability.

The Integral component addresses errors that have accumulated over time. This component eliminates errors in steady state but can slow down response times if the setting is too high.

Derivative: This component is a derivative that predicts errors in the future based on temperature changes. This helps to reduce oscillations and overshoot, but an excessive gain in derivative can cause noise.

It is important to understand these parameters in order to achieve the delicate balance required for temperature control.

3. PID tuning methods

Each method has its advantages and limitations.

Manual Tuning

The manual tuning process involves trial and error, with each parameter being adjusted incrementally. This method requires patience but allows the user to customize settings for their application.

Ziegler-Nichols Method

Ziegler-Nichols is a tuning method that uses a classic technique to identify the oscillatory behaviour of a system. The method provides the initial gains for I, P and D, which are then refined.

Cohen Coon Method

This method works best for open-loop systems. The method calculates the parameters by analyzing how the system responds to an input step. This is a structured alternative to manual tuning.

Autotuning

Modern PID controllers have autotuning algorithms built in. They automatically change the parameters in response to system feedback. This simplifies the tuning process.

The user's knowledge and system requirements will determine the best method to use.

4. The Step-byStep Tuning Procedure

Safety and Initial Installation

Be sure that the PID controller is operating in safe and stable conditions before tuning it. To prevent tuning errors, disconnect power sources and check sensor connections.

Adjusting Proportional gain

Increase the gain proportionally (P) to start the oscillations. Reduce the gain gradually until oscillations are gone, and the system is responsive but stable.

Optimising Integral and Derivative Values

Then, use the integral gain to remove steady-state error. The value should be adjusted incrementally to ensure the system is responding without delay. Add derivative gain (D), to improve the response time and reduce overshoot.

Validating and Testing the Settings

Test the system in different conditions after adjusting the parameters to make sure it performs consistently. Monitoring temperature stability, responsiveness and error margins. Recalibrate if necessary.

5. Common Challenges with Solutions

It can be difficult for newbies to tune a PID controller. Some common issues are:

Oscillations Excessive gain proportional can lead to oscillatory behaviour. To stabilize the system, reduce the gain parameter or change the derivative parameter.

Overshoot High integral gains may cause overshoot. Reduce the integral parameter in order to resolve this problem.

Sluggish Response Insufficient gain proportional can lead to a sluggish response. To improve responsiveness, increase the gain in incremental steps.

To solve these problems, you need to be very careful and make iterative changes.

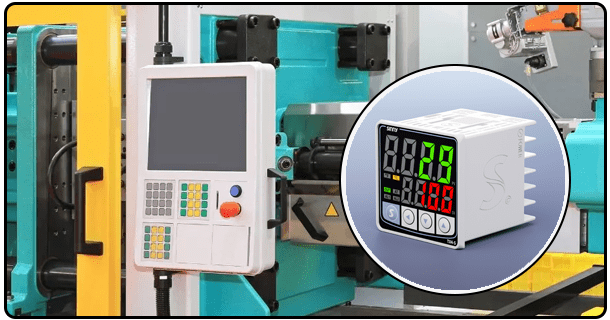

6. Uses of PID controllers

The PID temperature control is widely used in many industries, applications and sectors.

Industrial processes: Maintaining exact temperatures during manufacturing processes such as metal annealing and plastic molding.

Food & Beverage : Optimizing temperatures for brewing, fermenting, and cooking to maintain product quality.

HVAC System: Controlling heating and cooling in buildings to improve energy efficiency.

Projects Popular with hobbyists, for home-brewing and experiments on a small scale.

PID temperature controllers are versatile and a valuable tool in the field of temperature control.

7. FAQs

PID tuning: What is it?

PID tuning involves adjusting proportional, integral and derivative parameters in a PID control to maximize its performance.

How can I improve the accuracy of PID tuning?

Use structured tuning techniques like Ziegler Nichols and Cohen Coon to improve accuracy. Consider controllers that have autotuning features.

How difficult is it to tune PID for beginners?

Although tuning takes patience and practice to master, a simple step-by-step procedure can make the process easier for novices.

8. The conclusion of the article is:

The tuning of a PID controller is essential to achieving accurate and reliable temperature control. Understanding its parameters, choosing an appropriate tuning technique, and solving problems can help users unlock the potential of their PID temperature controller.

Don't forget that successful tuning takes patience, observation and willingness to experiment. This guide will help you achieve the best results.