Design of a Temperature Control System using PID Controller

Learn about the implementation and application of PID temperature controllers. Discover tuning techniques, future improvements, and challenges for accurate temperature regulation.

1. Introduction

The use of temperature control systems is essential in many industries. They ensure precision and reliability for processes like manufacturing, HVAC, food storage and lab operations. PID controllers, with their Proportional-Integral-Derivative algorithm, have emerged as a gold standard for maintaining stable temperatures in dynamic environments. The project will design and implement an automated temperature control system using PID technology, providing insights into the controller's principles, tuning methods, and applications. This project is relevant in academic as well as industrial settings, since it combines theoretical and practical knowledge.

2. Project Objectives

This project's primary objectives are:

Create a temperature control system that works using a PID.

Achieve precise temperature control suitable for various applications.

Understanding the fundamentals of PID tuning mechanisms and feedback mechanisms.

Analyze the performance and find areas of improvement.

The project will contribute to the development of both practical and technical problem solving skills.

3. Materials and Components Required

The following materials and components are needed to design the temperature control system:

Hardware

Microcontroller An Arduino Uno, or Raspberry Pi is the brain that runs the PID algorithms.

Sensors for Temperature: The LM35 and DS18B20 sensors provide temperature measurements in real time.

Actuators : To control the temperature, you use a heating element such as nichrome or a cooling fan.

Power Supply : Delivers constant power to all the components.

Modules of Relay act as switches for controlling actuators.

Programing Environment : Arduino IDE, or Python to code the PID algorithm.

Simulation Tool: MATLAB and Proteus for modeling and analysis.

Combining these elements of hardware and software, this system can achieve temperature control with precision.

4. Principles of Operation for the PID Controller

PID controls work on the basis of a feedback mechanism which adjusts output in order to minimise the difference between desired temperature and actual temperature. The three main terms that describe its operation are:

Proportional (P): The term is used to adjust the computer in proportion to the magnitude of the error.

Integral: This term addresses cumulative past mistakes and eliminates steady state offset. It also ensures stability on a long-term basis.

Derivative (D): This term is used to predict future errors by analyzing the rate at which changes occur. It allows the system to react proactively.

This three-component system allows for precise temperature control even under fluctuating conditions.

5. Project Design & Implementation

System Architecture

The architecture of the system consists interconnected sensors and actuators as well as a PID control. The microcontroller calculates error based on real-time temperature data. It adjusts output to heating elements or cooling fans based on the PID parameters.

Circuit Design

Circuit design includes wiring temperature sensors, relay modules and actuators into the microcontroller. Schematic diagrams include connections for the power supply, and interfaces.

Programming

PID algorithms can be coded using Arduino IDE, Python or Python. The code includes:

Initialization of sensors, actuators and other devices.

Calculating errors and reading temperature data.

Implementing PID for output adjustment.

The system can be tested once the code has been uploaded onto the microcontroller.

6. Tuning a PID Controller

For optimal performance, tuning the PID controller can be crucial. Common methods include

Ziegler-Nichols Method:

Test the system to determine its critical gain, oscillation period and other parameters.

You can adjust PID parameters using predefined formulae.

Trial-and-Error Approach:

Test your system in different conditions.

Modify PID parameters gradually to obtain desired responsiveness and stability.

The system will maintain the temperature you want if it is tuned properly.

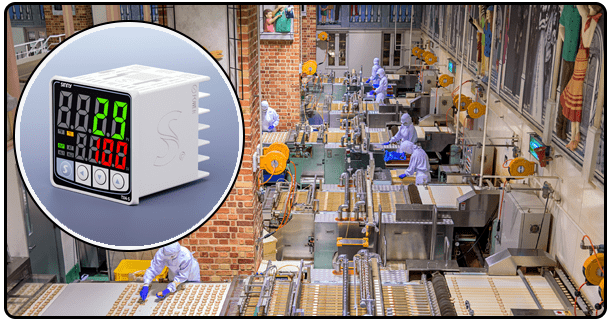

7. Application of Project

There are many applications for temperature control systems using PID controllers:

Industrial Automation : Ensure precision in manufacturing processes.

HVAC Systems: Maintaining comfortable indoor climates.

Food Storage : Preventing food spoilage through temperature regulation.

Laboratory equipment: Supports research and experiments with controlled conditions.

The applications showcase the versatility of this system and its importance in various industries.

Challenges & Solutions

When implementing a project, there may be several obstacles to overcome:

Sensor Inaccuracies: Regular calibration ensures accurate readings.

Delay Actuator: High-quality actuators reduce response times.

Bugs in Software: Debugging the code thoroughly eliminates all errors.

These challenges must be addressed to ensure smooth and reliable system performance.

8. Future Enhancements

Consider the following improvements to improve your system:

IoT integration: Remote monitoring and control through cloud platforms.

Advanced Sensors : Use sensors that are more accurate and have a faster response time.

AI Driven Adaptive control: Use machine learning algorithms for dynamic optimization of PID parameters.

The project is now at the cutting edge of technology innovation.

This temperature control system demonstrates how theoretical knowledge can be combined with real-world implementation. The system is able to regulate temperature accurately and consistently by leveraging PID principles. This allows it to meet the requirements of different industries. The system is capable of delivering endless innovation and efficiency with the right tuning and enhancements in future. The project is not just a way to enhance technical knowledge, but it also helps solve real world problems.

- The PID tuning of temperature control valves: methods, applications, and challenges

- A Guide to the TA4 Temperature Controller with SNR and PID: A Comprehensive Guide