Discover How Does a Temperature Controller Work: A Comprehensive Guide

Learn how to use a temperature controller with our detailed guide. Understand the types, components, setup, and operation for precise temperature control in various applications.

1. Introduction

Temperature controllers are indispensable tools used across industries and disciplines, from manufacturing and food processing to HVAC systems and more, for maintaining precise temperature settings with precision. Understanding their best use will both increase productivity and ensure safety.

2. Temperature Controller Types

There are various kinds of temperature controllers designed for various uses; here are the main ones.

On/Off Controllers

An on/off controller is one of the easiest forms, providing control when temperatures surpass setpoint and switching output on or off when temperature exceeds this point. Ideal for applications where precise control isn't critical.

Proportional Controllers

Proportional controllers offer more refined temperature management by adapting output proportionally to any variances between setpoint and measured temperatures, helping reduce oscillations around setpoint. This feature helps prevent oscillations near setpoint from taking place.

PID Controllers

PID (Proportional-Integral-Derivative) controllers are highly sophisticated controllers. By combining proportional control with integral and derivative adjustments to reduce errors while keeping temperatures stable, these are perfect for applications requiring high precision.

3. Components of a Temperature Controller

Temperature controller systems generally consist of three key elements that combine into an effective solution:

Sensor (Thermocouple or RTD)

A temperature sensor measures and transmits temperature measurements back to its controller; such devices include thermocouples and RTDs (Resistance Temperature Detectors).

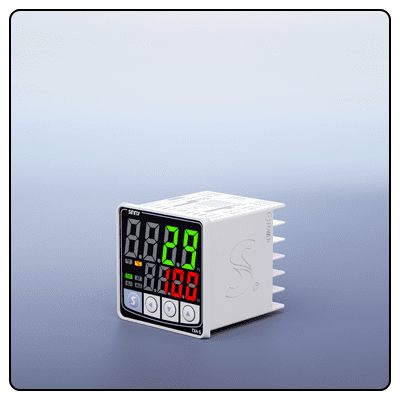

Controller Unit

The Controller Unit receives data from sensors and uses it to make adjustments that maintain or reach setpoint temperatures, from simple on/off switches all the way up to PID controllers for temperature regulation.

Output Device (Heater or Cooler, etc)

When connected with its controller, an output device such as a heater or cooler receives signals to adjust temperatures according to instructions from said controller.

Establish the Temperature Controller

Proper configuration of a temperature controller is crucial to its successful use and operation, so follow these steps when setting one up:

4. Wiring Your Controller:

Soldering Sensor To The Controller

* Attaching Your Sensor: Once connected securely to the controller according to manufacturer instructions for wiring it properly.

Connect Your Output Device Securely: It is essential that any output devices attached to a controller be securely attached, making sure all connections are tightened properly and securely fastened to each connection point.

* To Achieve Successful Operation

Before turning on, be certain that the controller is connected to an appropriate power source - any incorrect voltage could potentially damage its device and render it nonfunctional.

* Initial Configuration: Define and customize the temperature setpoint you would like; with PID controllers, also define and modify their control parameters such as proportional, integral and derivative settings.

Operation

After being installed, temperature controllers are ready for operation. Below are its key steps of use.

Monitoring the Temperature

*Read Current Temperature for Proper Control Your controller's display will provide the current temperature; make sure it remained close to its setpoint by keeping an eye on this number.

Adjust the Settings

* Tuning Setpoint and Control Parameters When necessary, fine-tune setpoint and control parameters to achieve optimum performance.

Safety Checks

* Conduct Regular Safety Inspects | It is imperative that we conduct periodic safety inspections to detect loose wires or potentially compromised connections so as to stay ahead of any potential safety concerns and ensure our connections continue working as intended.| It is imperative that we conduct periodic safety inspections to detect loose wires or potentially compromised connections so as to stay ahead of any potential safety concerns and ensure our connections continue working as intended.

* Perform Routine Maintenance and Calibration: For optimal accuracy, regularly calibrating both controller and sensor can ensure their accuracy remains consistent over time. This step ensures the highest possible precision.

5. Troubleshooting

Even after following all necessary setup and operation steps, issues may still arise that require solving. Here are some frequently experienced difficulties and solutions:

* Inaccurate Temperature Readings: To achieve accurate temperature readings, inspect and recalibrate any sensors for signs of damage or misplacement before recalibrating as required.

*Controller Not Responding: Verify the controller is receiving power and all connections are secure.

*Output Device Isn't Working: Verify that the output device is functioning appropriately and connected correctly with its controller.

If issues persist, refer back to your manufacturer's manual or seek professional assistance.

6. Conclusion

Using a temperature controller effectively requires understanding its components, setup, and operation. By following the outlined steps, you can ensure precise temperature control in your applications, enhancing efficiency and safety.

- How to Use a Temperature Controller: A Comprehensive Guide

- Top Temperature Control Solutions for Different Applications: An In-depth Guide