Top Temperature Control Solutions for Different Applications: An In-depth Guide

Discover the top temperature control systems available for industrial, commercial, medical and automotive use. Gain knowledge on on-off, proportional and PID controllers and their key components to select a system tailored to your requirements.

1. Introduction

Temperature control systems are vital in many industries and applications, providing optimal performance, safety, and efficiency. From industrial processes to medical equipment, temperature controls are indispensable in maintaining precise temperatures at precise points within equipment or facilities. This article introduces top temperature control systems and their applications and components so readers can decide when to find one to meet their unique requirements.

2. Overview of Different Applications

Temperature control systems have wide-ranging uses in industrial, commercial, medical, laboratory, and automotive industries. Each application may need tailored temperature systems to achieve the best performance results and meet specific application-related demands.

Types of Temperature Control Systems

On-Off Controllers

* Fundamental Function: On-off controllers provide the simplest temperature regulation systems. They work by activating or deactivating heating/cooling devices when temperatures deviate from setpoint, making this type of controller ideal for applications where precise control over temperatures is not essential.

*Common Applications: On-off controllers are typically found in simple heating systems in residential settings, like home thermostats. In industrial applications with acceptable temperature variations, on-off controllers are also frequently utilised as thermostats.

Proportional Controllers

* How They Operate: Proportional controllers offer more refined temperature regulation than on/off controllers by adjusting output depending on any differences between set point temperature and actual temperature - thus providing smoother temperature regulation with reduced oscillations and fluctuations.

* Advantages Over On-Off Controllers: Proportional controllers offer more stable temperature regulation, decreasing wear-and-tear damage on equipment caused by frequent switching and improving energy efficiency by limiting overshoot and undershoot temperature fluctuations.

* Applications: Temperature controllers are frequently employed in industrial processes where maintaining stable temperatures is critical, including chemical processing, food production and HVAC systems.

3. PID Controllers

* Explaining Proportional-Integral-Derivative Control: PID (Proportional-Integral-Derivative) controllers are widely acclaimed and effective temperature regulation solutions featuring proportional controls combined with integral and derivative actions for precise yet stable temperature regulation.

* PID Controller Advantages and Precision: PID controllers offer exceptional accuracy for maintaining set temperatures with minimum variance, perfect for applications requiring tight temperature regulation, such as manufacturing processes, laboratory environments, and sophisticated HVAC systems.

* Applications: PID controllers have numerous uses in various environments, from industrial automation and medical equipment to environmental chambers, and their ability to handle complex temperature regulation tasks makes them indispensable tools in many high-precision applications.

4. Applications of Temperature Control Systems

Industrial Applications

* Manufacturing Processes: Temperature control systems in an industrial setting are critical in guaranteeing product quality and process efficiency. In manufacturing processes like plastic moulding and metal fabrication, precise temperature regulation ensures that desired outcomes are realised.

Temperature regulation in chemical processing industries is essential in maintaining optimal conditions and guaranteeing safety, helping ensure consistent product quality while also helping prevent dangerous situations from emerging. Accurate temperature management allows manufacturers to ensure safe operations.

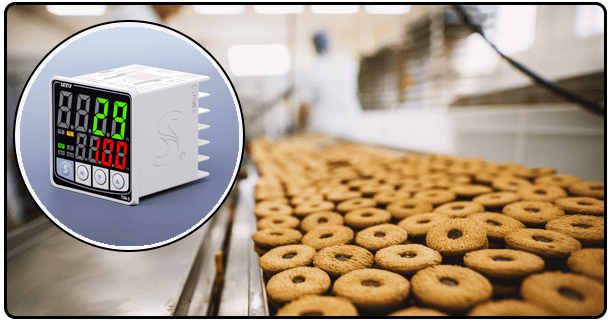

* Food and Beverage Industry: Temperature control in food production processes such as pasteurisation, fermentation and refrigeration is crucial to food safety and quality. Maintaining an ideal temperature range ensures product excellence.

Commercial Applications

* HVAC Systems for Buildings: Temperature control systems are key to creating comfortable work environments while protecting sensitive equipment and providing comfort to employees and equipment alike. HVAC systems in buildings ensure an ideal indoor temperature setting to create the utmost comfort for those within.

* Data Centers: Data centres require accurate temperature controls to protect electronic equipment, such as servers, from overheating and ensure its long-term viability and upkeep. Proper temperature maintenance can ensure reliability and longevity within their infrastructure.

* Retail Environments: Temperature control in retail settings can extend the shelf life of products while simultaneously creating optimal shopping environments for customers. When properly implemented, temperature regulation improves shopping experiences for all involved.

5. Medical and Laboratory Applications

* Medical Equipment: Temperature control systems play a vital role in medical equipment functioning effectively, such as incubators, autoclaves and cryogenic storage units, which rely on precise temperature regulation to function as intended.

* Laboratory Environments: Lab environments require precise temperature regulation to conduct accurate experiments and research studies with reproducible results. Maintaining stable temperatures for accurate scientific investigations requires today's highest-grade temperature control technology.

* Pharmaceutical Storage Facilities Utilizing temperature regulation is employed at pharmaceutical storage facilities to preserve medications and vaccines in optimal condition for their intended uses, keeping their effectiveness and safety secure for years after being purchased from retail pharmacies.

Automotive Applications

* Engine Temperature Control: In the automotive industry, temperature control systems are vital in maintaining optimal engine and climate systems performance. Engine temperature management is essential in avoiding overheating while guaranteeing peak performance levels.

* Climate Control Systems in Vehicles: Climate control systems in vehicles provide passengers with a comfortable atmosphere, regardless of external weather conditions, by regulating temperature within. These systems help increase passenger comfort and ensure their safety while travelling in comfort and style.

Key Components of Temperature Control Systems

Sensors

* Types: Sensors are key elements in temperature control systems for accurately measuring temperature. Common sensors include thermocouples, resistance temperature detectors (RTDs) and thermistors.

* Role in Temperature Control:Sensors play an essential part in temperature regulation by providing accurate temperature readings that enable precise temperature regulation. They detect temperature variations, sending alert signals to the control unit so adjustments may be made as required.

Control Units

* Processing Sensor Data: Control units take in data received from sensors and make necessary adjustments to maintain an ideal temperature environment. They utilise algorithms to determine an apt response, whether this involves activating heating elements or increasing cooling fan speeds.

* Making Adjustments: Temperature control units serve as the brains of temperature management systems, providing precise and stable temperature regulation. They constantly monitor readings from sensors onboard the unit as it makes real-time adjustments necessary to reach and keep at their set point temperature.

Heating/Cooling Elements

* Types and Functions: Heating and cooling elements are essential in controlling system temperatures. Heating elements, such as electric heaters or heat exchangers, increase it, while cooling elements, like fans or refrigeration units, decrease it.

* Role in Temperature Control: These elements work alongside control units to help achieve and sustain desired temperatures, providing heating or cooling as required to reach and maintain that goal.

6. Heat Exchangers

in Efficient Temperature Transfer:

They are crucial in effective temperature transfer between various environments and systems, particularly the hospital setting.

Temperature transfer systems provide efficient temperature regulation by exchanging heat between fluids. They allow heat exchange for effective temperature regulation.

* Common Applications: Heat Exchanger Applications: Heat exchangers are widely utilised within industrial processes, HVAC systems and automotive applications to achieve desired temperature conditions and enhance temperature control systems' efficiencies by improving heat transfer rates. They help preserve optimal operating temperatures with maximum effectiveness by keeping temperatures consistent at optimal conditions.

Choosing the Right Temperature Control System

* Factors to Consider: Selecting the right temperature control system depends on various factors, including the application, required precision, and budget. It's essential to consider the specific needs of the application and compare different systems to determine the best fit.

* Contrasting Systems: When selecting a temperature control system, consider factors like response time, accuracy and ease of use as part of your selection criteria. Also, could you investigate each controller type's benefits and drawbacks to make an informed decision?

* Tips for Selecting an Effective System: To select an effective temperature control system, consider your application's specific needs first and choose systems that offer desired precision, reliability, and integration ease. Consulting experts or reviewing case studies is often also an invaluable asset when making this choice.

7. Conclusion

Temperature control systems have become essential to ensure maximum performance and safety across industries and applications. From simple on/off controllers to sophisticated PID systems, temperature regulation technology offers precise temperature regulation. By understanding the different types of temperature controls available and their uses, you can make informed decisions and choose a system best suited to your requirements. Technology advances, offering even greater precision and efficiency in temperature regulation systems.

- Discover How Does a Temperature Controller Work: A Comprehensive Guide

- Modern Temperature Control Systems: Improve Performance & Efficiency