Enter The World OF What Is A Digital Temperature Controller?

Enter the world of digital temperature controllers to learn the role, benefits, and technology behind precise environmental management across many applications.

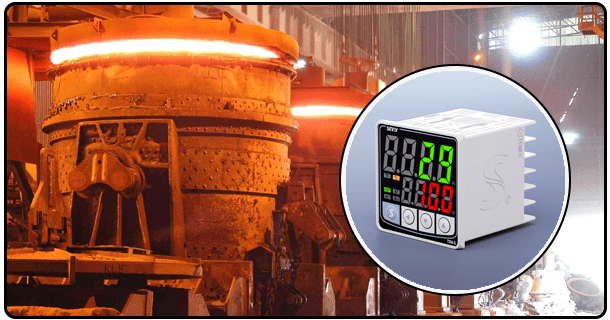

Digital temperature controllers have revolutionized how we manage and maintain temperatures across many environments, from industrial applications to everyday consumer products. From precision, efficiency, and convenience for industrial purposes to precise controls for consumer products - digital controllers offer precision, efficiency, and convenience! In this article, we explore digital controllers from their components to benefits and future trends within temperature management technology.

1. Introduction to Digital Temperature Controllers

A digital temperature controller is an electronic device that tracks and maintains system temperatures within specified parameters. Analog-to-digital conversion represents an advancement in control technology, with higher precision capabilities for managing complex processes more precisely.

Basic Principles of Digital Temperature Control

At their core, digital temperature control systems consist of three components: sensors to sense temperature, setpoints representing desired levels, and control elements that regulate them. A digital controller then processes sensor input against its setpoint value to generate signals to control elements to keep temperatures within acceptable parameters.

Components of a Digital Temperature Controller The Key elements of a digital temperature controller include:

* Microprocessors:these serve as the brain of any controller system, processing input data and running control algorithms.

* Digital Interfaces: Digital interfaces allow users to communicate directly with a controller, set parameters, and monitor a system.

* Sensors: Temperature sensing devices such as thermocouples and RTDs deliver accurate temperature readings to controllers for analysis.

2. Advantages of Digital over Analog Controllers

Digital temperature controllers present several distinct advantages over their analog counterparts:

* Precision: They deliver more precise temperature readings and control.

* Programmability: Users can program digital controllers specifically for different tasks and conditions.

* Automation: By automating complex processes, automation software reduces manual intervention while streamlining procedures.

3. Types of Digital Temperature Controllers

There are various digital temperature controllers designed for multiple uses; there's sure to be something suitable.

* On/Off Temperature Controllers : These are the simplest form, turning heating or cooling elements on or off as necessary.

* Proportional Temperature controllers: They adapt output according to temperature changes by proportionally increasing or decreasing pr as it changes from what was programmed.

* PID Temperature Controllers: They use proportional, integral, and derivative control techniques in order to accurately regulate temperatures with high precision.

* Autotune PID Temperature Controllers: Thy automatically optimize performance by automatically adjusting their PID settings to achieve peak efficiency.

* Multiloop Temperature Controllers: Ideal for managing complex systems with multiple control loops.

* Safety Limit Temperature Controllers: Ensure the system stays within safe temperature parameters by installing safety limit controllers to regulate its temperatures.

4. Applications of Digital Temperature Controllers

Digital temperature controllers have many uses; here are just a few applications of their use:

* Industrial: Temperature control in HVAC systems, food production facilities, and chemical processing is crucial to guarantee product quality and process efficiency.

* Consumer Products: Refrigerators, air conditioners, and water heaters all use digital controllers for consistent performance and energy savings.

5. Picking Out an Appropriate Digital Temperature Controller

There are various factors to keep in mind when selecting an appropriate digital temperature controller:

* Input Sensor Type: The controller should be compatible with any temperature sensors used for optimal operation.

* Temperature Range: It must meet your system's thermal demands.

* Output Requirement: For control elements to function effectively, their output requirements must be appropriately provided by their controllers.

* Control Algorithm: The appropriate algorithm is essential for implementing an efficient and accurate temperature regulation system.

6. Future Trends for Digital Temperature Control

Digital temperature control holds promise as an industry trend; emerging trends include:

* Internet of Things (IoT): With IoT-enabled controllers, monitoring and adjustment can be done remotely for greater control and flexibility.

* Smart Systems: Advanced algorithms and machine learning techniques can further optimize temperature controls to decrease energy use while improving system responsiveness and decreasing system costs.

Digital temperature controllers have become an essential element in modern temperature management systems. They provide precise temperature management that adapts to various applications while remaining user-friendly. Their ongoing evolution promises even further advances in efficiency, accuracy, and connectivity over the coming decades.