How Do Temperature Controllers Work?

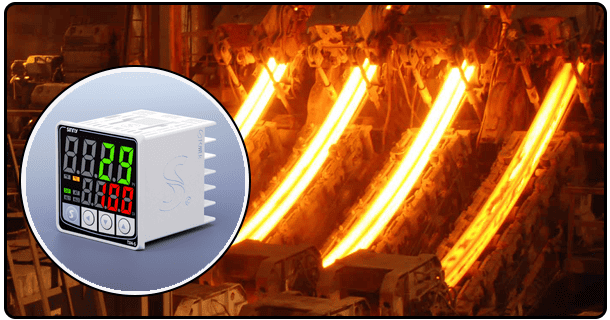

Explore the mechanics of temperature controllers with our detailed guide! Learn about their types, operations, and applications - essential devices for maintaining ideal temperatures!

1. Introduction to Temperature Control

Temperature control is an integral component of many industrial, commercial, and residential applications. Temperature controllers measure and manage temperatures within specific environments or systems--an essential function to ensuring product quality, safety, and operational efficiencies.In this article, we investigate temperature controllers' workings, components, principles, and applications.

The involves maintaining a comfortable level in any space or substance through temperature controllers - devices used to monitor and adjust temperatures based on predefined setpoints - both inside industrial furnaces as well as large home appliances like ovens and fridges as well as small household devices like ovens and fridges. Temperature controllers can be found everywhere from industrial furnaces and large home appliances like ovens and fridges right through to small household items like ovens and fridges.

2. Basic Principles of Temperature Control

At the core of temperature control lies feedback loops - either open or closed loops:

* Open Loop Control: With open loop control, a controller issues an ongoing command to either heating or cooling devices without taking into consideration their actual temperature - comparable to driving without looking at your speedometer!

* Closed Loop Control: Also referred to as feedback control, this system constantly measures actual temperature readings and makes adjustments that match desired setpoint values - similar to cruise control on a car where speed adjustments occur automatically to match set speed targets.

3. Components of Temperature Controllers

A temperature controller typically features four main parts. These components include:

* Sensors: These devices, including thermocouples or RTDs (Resistance Temperature Detectors), measure actual temperatures.

* Setpoint: This term denotes the temperature that the system attempts to maintain as its target target temperature.

* Output Signal: This signal activates heating or cooling devices in order to bring temperature closer to setpoint.

4. Temperature Control Systems

There are various kinds of temperature control systems, each offering their methods of operation:

* On/Off Control: In its purest form, this form of temperature regulation allows a controller to switch the output fully on or off as required to regulate temperatures.

* Proportional Control (Prop. Ctr): This system adjusts its output proportionally to any differences between the actual temperature and the setpoint temperature.

* PID Control: PID stands for Proportional Integral and Derivative calculations to achieve precise temperature regulation. This system offers unrivalled precision.

5. Operation of Temperature Controllers

A temperature controller's operation can be broken down into four steps:

1. Measurement: Reaping Data From Sensors First, data is transmitted to the controller from sensors measuring current temperature levels.

2. Comparison: this step compares current measured temperatures against their setpoint temperatures set within its program.

3. Calculation: Depending on the type of controller, output calculations are made to decrease the deviation between the actual temperature and setpoint.

4 Adjustment: Once this process has been completed, the controller sends signals to the the heating/cooling device to make necessary temperature changes accordingly.

5. Feedback: Once adjusted temperatures have been measured and reported back, their information is fed back into the controller for further adjustments as necessary.

6. Temperature Controller Applications

Temperature controllers have numerous uses: they're employed across industries, from manufacturing and engineering to medical device and pharmaceutical applications.

* Industrial Processes: These include maintaining temperature-regulated furnaces, boilers and heat exchangers.

* Food Industry: Temperature controllers in ovens, refrigerators, and freezers ensure food safety by managing temperatures to ensure safe conditions for these appliances.

* Chemical Processing: Used to manage chemical reactions that require specific temperatures.

* Consumer Products: Such as air conditioners, water heaters and electric blankets.

- How To Calibrate A Digital Temperature Controller?

- Enter The World OF What Is A Digital Temperature Controller?