How Does a PID Temperature Controller Work: A Detailed Guide

How Does a PID Temperature Controller Work: A Detailed Guide

Learn about the components, setup, operation, and applications of PID controllers for precise temperature control.

1. Introduction

A PID (Proportional-Integral-Derivative) temperature controller is an advanced tool used to precisely maintain desired temperatures across many industries - manufacturing, food processing and HVAC among them - including manufacturing. Understanding its functioning will increase both your efficiency and reliability of operations.

2. What Is a PID Controller?

A PID controller is a widely utilized feedback mechanism found in industrial control systems that constantly calculates an error value as the difference between its desired setpoint and an measured process variable, then attempts to minimize this value through tweaks made to process control inputs.

Proportional Control (P)

Proportional control produces output values which are proportional to current error values. Adjustments to this proportional response can be made by multiplying error by an adjustable constant known as proportional gain - where higher proportional gains lead to larger output changes for any given error value.

Integral Control (I)

Integral control addresses past errors by adding up their total cumulative effect over time; when an error has persisted over a significant span, its value accumulates further, helping eliminate residual steady state error that might otherwise remain from using only proportional controllers alone.

Derivative Control (D)

The derivative component predicts future errors based on their rate of change and provides a damping effect, decreasing overshoot while increasing stability for systems.

3. How PID Controllers Operate

A PID controller works by continuously adjusting its control output in order to minimize differences between its setpoint and process variable and error between these variables, including any variables introduced through processes like chemical reactors or refineries. Below is an in-depth breakdown of each component's role in this process:

Proportional Control (P)

Proportional control works by adjusting output proportionally with any current error; when there's a big mistake, output increases significantly, but with smaller errors it stays minimal, making for quicker process variable adjustments toward their setpoint values. This provides for smooth and quick process variable movements within its control range.

Integral Control (I)

Its Integral control systematically accumulates errors over time, then adjusts output accordingly in order to eliminate any remaining steady-state error. Thus, even small deviations that persist will eventually be rectified to ensure the process variable reaches and remains at its setpoint.

Derivative Control (D)

Derivative control uses past error trends as the basis of its future trend prediction, helping reduce overshoot and settle times while making systems more stable by damping response to setpoint oscillation. By dampening response to setpoint oscillation, derivative action prevents process variables from oscillating around setpoint values.

4. Components of a PID Temperature Controller

A typical PID temperature controller consists of three major parts. These components include:

Sensor (Thermocouple or RTD)

A temperature sensor measures temperature and sends its data directly to a controller, with thermocouples or RTDs (Resistance Temperature Detectors). Various characteristics like accuracy, range and response time influence their selection as ideal choices for temperature measurements.

Controller Unit

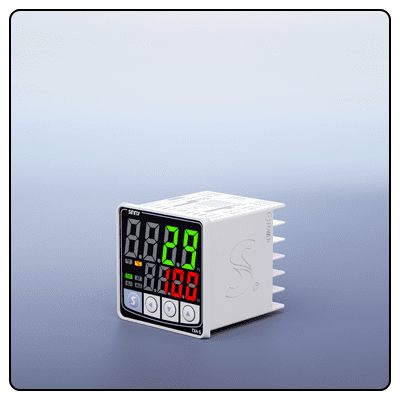

A controller unit processes sensor data and makes adjustments necessary to maintain setpoint temperature, either as an independent device or part of larger control system. PID algorithms are utilized by this unit for output calculation.

Output Device (Heater or Cooler, etc)

An output device such as a heater or cooler receives signals from its controller to help regulate its temperature accordingly, responding quickly and accurately in order to meet desired settings. It must respond swiftly but accurately in order to meet controller commands for maintaining optimal results.

5. Setting Up a PID Temperature Controller

Proper setup is critical to ensure optimal operation of a PID temperature controller. Please follow these steps:

Wiring the Controller:

* Connecting the Sensor: Before connecting any sensors to the controller, ensure they have been connected in accordance with manufacturer specifications for correct wiring in order to reduce errors in connection.

Connect the Output Device: Secure all connections correctly configured before attaching an output device to a controller and making sure all are secure and in working condition.

* Verifying Correct Voltage and Power Supply: Make sure the controller is connected to its appropriate power source; improper voltage can damage and impair performance of devices.

* Initial Configuration: Establish the temperature (setpoint). PID controllers allow users to customize control parameters (proportional, integral and derivative settings) based on specific application needs.

6. Operation and Monitoring

After installing and activating the PID temperature controller, it can now be operated and monitored as desired. Here are the essential steps.

Reading the Current Temperature

* Monitoring the Display: To keep an accurate record, regularly review your controller's display to assess current temperature readings to make sure they stay within setpoint limits.

Adjusting Settings

* Tuning Setpoint and PID Parameters for Maximum Efficiency: When necessary, tweak both setpoint and PID parameters until they provide optimal performance in your specific application - this may involve trial and error to find what settings work best in terms of results and efficiency.

Safety Checks

* Conduct Regular Safety Inspections

To Ensure That All Connections Are Secure: It is crucial that regular safety checks be conducted to detect loose wires or defective connections so as to maintain reliability and ensure systemic safety.

* Regular Maintenance and Calibration: For accurate control system operation and to avoid unexpected failures, calibration should take place periodically on both controller and sensor units. Proper care ensures optimal system functioning by eliminating unexpected faults that might otherwise arise from lack of regular upkeep and calibration.PID temperature controllers have become widely utilized due to their accuracy and dependability in various fields of application, with common examples including:

Industrial Processes

PID controllers are commonly utilized in industrial processes to maintain precise temperatures in reactors, furnaces and other equipment in order to guarantee consistent product quality as well as efficient operations.

HVAC Systems

HVAC (Heating, Ventilating and Air Conditioning) systems use PID controllers to efficiently regulate temperature. They make for a pleasant indoor climate while at the same time optimizing energy use.

Food Processing

In food production and processing environments, maintaining precise temperatures is paramount to food safety and quality assurance. PID controllers help achieve this through accurate temperature regulation.

PID controllers are commonly utilized in laboratories for controlling various equipment like incubators, ovens and environmental chambers to maintain stable temperatures for experiments and tests.

7. Troubleshooting

Even with proper setup and operation, problems may still arise from time to time. Here are some typical issues and their possible resolutions:

*Inaccurate Temperature Readings: To correct inaccurate readings, inspect and recalibrate as necessary the sensor - in case it has become damaged. Recalibration will help ensure accurate temperature readings are obtained.

* Controller Not Responding: Verify the controller is receiving power and all connections are secure before searching for loose wires or components that might need attention.

*Output Device Not Working: Verify that the output device is properly connected and functioning according to specifications; replace any malfunctioning parts if required.

8. Conclusion

Understanding how a PID temperature controller works and how to set it up correctly can significantly enhance the efficiency and reliability of your temperature control processes. By following the outlined steps and regularly maintaining your system, you can ensure precise temperature control in various applications.

- How PID Temperature Controllers Work: Components, Mechanisms, and Applications

- How to Use a Temperature Controller: A Comprehensive Guide