The Design of Temperature Control PIDs: Steps to Follow, Application and Future Trends

Learn how to design PID temperature regulators. This includes key steps, tuning techniques, applications and future trends.

1. Introduction

Basics of PID Control

To regulate temperatures effectively, PID controls rely on three components:

Proportional term (P) : This term responds to the magnitude between the current error and the desired temperature (setpoint). The control output is adjusted proportionally according to the size of the error.

Integral Terms (I). The integral term addresses accumulated errors and eliminates offset. This ensures long-term accuracy.

Derived Term (D).. By using the rate of changes to predict future errors, derivative terms allow proactive adjustments and improve system responsiveness.

This feedback loop allows the components to work in harmony in order to keep temperatures at desired levels even when environments are dynamic.

2. The Components in a Temperature Controller

The PID temperature controller includes several important components.

Temperature Sensors: Thermocouples and RTDs provide accurate data in real time.

Actuators These are mechanisms that include heating elements and cooling devices. They implement the adjustments dictated to them by a PID controller.

PID controller This unit calculates errors and produces control signals for stability.

These components work together to form a temperature control system that is effective.

Steps for PID Design

This involves following several important steps.

System Analyses

Start by analysing the dynamic of the system. Determine key parameters, such as:

Setpoint desired.

Temperature range.

Time requirements for response

External factors and potential disturbances.

The analysis provides the basis for choosing appropriate PID parameter values.

3. Controller Design

Configure the PID controller based on system analysis. It involves:

Choose a suitable formula to calculate the Proportional gains, Integral and Derivative Gains.

Ensure compatibility of sensors and actuators

Set initial parameters of proportional integral and derivative terms.

Simulating and Testing

Use simulation software like MATLAB and Simulink for the modeling of your system. The simulations allow you to see how the PID responds in different situations, and refinements can be made before implementation. Validate the performance of your design by testing it in realistic scenarios.

4. PID Controller Tuning

The controller must be tuned to achieve optimal performance. Popular tuning methods include

Ziegler-Nichols Method

The following is a structured approach:

Set integral and derivative terms at zero.

Increase the gain proportional until the oscillation of the system is felt.

The critical gain period and oscillation time are recorded.

Use predefined formulas to calculate PID parameters.

A Trial-and Error Approach

The system is tested under different conditions, and the PID parameters are adjusted gradually to reach desired responsiveness and stability.

Software-Assisted tuning

Using software like MATLAB and LabVIEW makes the process of tuning easier. The software platform provides advanced visualizations and automated calculations to make precise adjustments.

Each approach offers unique benefits, which allows users to choose the best method for their particular system.

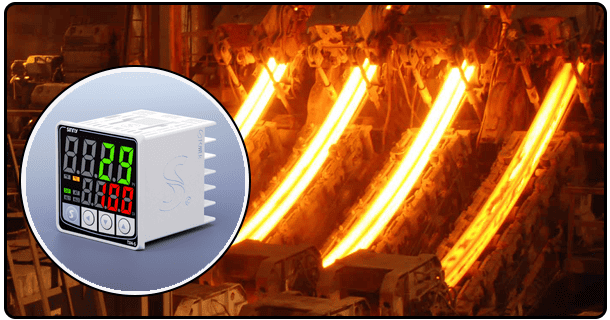

5. Application of PID Temperature Controls

Temperature control is a common application of PID controllers in many industries.

Industrial Processes:

To ensure the quality of chemical products, it is important to maintain a precise temperature.

For consistent operation, the food processing industry relies on stable temperature.

HVAC System

PID controllers are used to maintain an optimal indoor climate while optimising energy consumption.

Laboratory Equipment

For reliable scientific research and tests, it is often necessary to use exact temperatures.

Energy Systems:

The versatility and importance of PID temperature controllers is demonstrated by these applications.

6.PID Design Challenges

When designing or implementing PID controls, there are several issues that may come up:

Sensor Inaccuracies

Actuator delays

Temperature control systems can oscillate or become unstable if actuators are slow to respond. These delays are minimized by high-quality actuators.

Environmental Disturbances

System stability can be affected by external factors such as changing loads and ambient temperatures. These dynamic conditions can be effectively addressed by adaptive control techniques.

By proactively addressing these issues, you can ensure the efficiency and reliability of PID controls.

Future Trends for PID Design

Key trends in PID controller design include:

IoT Integration

AI-Driven Adaptive Control:

Artificial intelligence algorithms optimize PID parameters dynamically based on data in real time, improving performance for complex systems.

Improved sensors

Sensor technology innovations provide greater accuracy and quicker response times. This increases the effectiveness of PID Controllers.

- The Design, Tuning and Application Guide for Temperature Control PID

- The PID tuning of temperature control valves: methods, applications, and challenges