How is the PID temperature controller used? A Comprehensive Guide of Applications and Benefits

Learn about the applications of PID temperature controls in various industries, including manufacturing, HVAC and healthcare. Discover their advantages, applications and future trends.

1. Introduction

Understanding PID Temperature Controllers

The PID controller regulates temperature with high accuracy in any system. A sophisticated feedback loop is at the core of this device. The feedback loop calculates the error between the target temperature and the setpoint temperature. It then adjusts the output of the system accordingly.

Three main components make up the controller: proportional, integral, and derivative actions. Each one plays a different role.

Proportional: This component responds immediately to an error. This component adjusts output in proportion to the magnitude of error.

Integer (I): This integral approach deals with errors that have accumulated over time. It eliminates residual differences and refines accuracy.

Derived (D): By analyzing rate of changes, the derivative component predicts errors in future. This component stabilizes and prevents system overshoot.

These components work together to create an integrated approach for temperature control. PID controllers are one of the best solutions available.

2. Industrial Manufacturing

PID controllers are used in many industrial processes. Maintaining a controlled atmosphere is important in all production processes, whether it's plastic molding, metalworking or chemical. You can, for example:

Plastic molding: The material is heated and cooled according to a specific rate, which prevents defects.

Production of Chemicals: Controls the reaction temperature to maintain consistency and safety.

Metalworking Manages temperature of furnaces and welders to produce high-quality results.

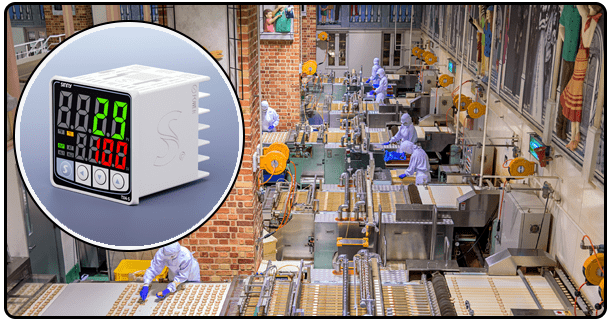

3. Food and Beverage Industry

Food and beverage manufacturers also rely heavily on temperature control PIDs in order to ensure consistency and product quality. Examples include:

Cookers and Ovens: Maintain consistent cooking temperatures.

Refrigeration units: Provide precise cooling during storage and transport.

Fermentation processes: Optimize the conditions of brewing and fermenting such as for beer or dairy products.

4. Medical and Pharmaceutical Fields

Precision is often the difference between life and death in medical and pharmaceutical applications. Temperature controllers with PID are essential for:

Incubators Provide precise conditions for neonatal or laboratory processes.

Autoclaves and Sterilizers: Maintain accurate temperatures to ensure proper disinfection.

Laboratory equipment: Control heating and cooling during chemical or biological experimentation.

HVAC System

HVAC systems, which include heating, ventilation and air conditioning, are another area where PIDs excel. PID controllers help to maintain an indoor climate while optimizing the energy usage by:

Temperatures of boilers

Air conditioners.

Heat exchangers.

5. Consumer Electronics

Many consumer products use PID temperature controls. PID temperature controllers are used in devices such as ovens, coffee makers, and thermostats to improve user experience.

Benefits of using PID temperature controllers

PID controllers are widely used because of the many benefits that they provide. They include:

Stability and High Precision: PID controllers are able to achieve exceptional precision and stability by continuously adjusting the system outputs.

Energy Efficient: These devices optimize energy use by meeting setpoints precisely, and reducing waste.

6. Limitations and Challenges

They also present certain challenges.

Tuning complexity: The configuration of the integral, proportional and derivative parameters is complex. Expertise may be required to get optimal performance.

The system's sensitivity to disturbances: Disturbances or external noise can affect the accuracy, requiring proper shielding and calibration.

Requirements for Initial Setup: Installation and integration of the system requires technical expertise and sufficient time.

By understanding these limitations, you can better implement and manage your project.

7. Future trends in PID temperature control

PID controllers continue to advance as technology advances. Their future is shaped by several trends:

- The Temperature PID Control Tutorial - Setup, Tuning and Applications

- What is PID Temperature Control (PID)? What are the advantages, principles, and applications of PID temperature control?