What is PID Temperature Control (PID)? What are the advantages, principles, and applications of PID temperature control?

1. Introduction

Proportional: The component reacts proportionally based on the differences between the setpoint desired and the current value. This component provides an immediate correction, but it may also leave some error in the steady state.

Integer (I): This integral part addresses past errors by adding up error values. It is crucial in eliminating steady-state errors.

Derived (D): By analyzing rate of change, the derivative component can predict future errors. The derivative component acts as a stabiliser, stopping the system from oscillating or overshooting.

These three components, when combined, create a feedback system that allows the outputs of the system to be adjusted in real-time, providing precise temperature control.

The Components in a PID System for Temperature Control

The following are the components of a typical PID Temperature Control System:

Controller PID Unit: Calculates the adjustments necessary to achieve the desired temperature.

Temperature sensor: Devices such as thermocouples and resistance temperature detectors, or RTDs, measure the temperature in the system.

Actuator Heaters or Coolers, like electric heaters and fans, that implement changes dictated by controller.

Power Supply and System Configuration: Makes sure the whole setup runs smoothly and efficiently.

The overall performance of the system is determined by each component's integration.

2. PID Temperature Control

Feedback loops are the key to PID's functionality.

Users can define the desired temperature (or setpoint) by themselves.

Temperature sensor: The PID controller receives temperature information from the temperature sensor.

To calculate error, the controller compares measured values with setpoints.

The controller sends signals from the actuator to determine the required adjustments using the components P, I and D.

It modifies system output in order to minimize error and bring the temperature close to setpoint.

A PID controller, for example, ensures that the temperature in a baking oven remains constant, which results in baked goods with an even texture.

3. PID Temperature Control: Advantages

PID Temperature Control has many benefits.

High precision: PID controllers are able to regulate temperature with unmatched accuracy by minimizing errors, maintaining stability and reducing the number of possible mistakes.

Adaptability These can be tailored for various systems whether they are industrial processes or household appliances.

Energy Savings: PID controllers can reduce energy usage by optimizing their outputs.

Economical: Although their initial set-up may be complicated, they have long-term advantages that outweigh any costs.

4. Limitations and Challenges

The PID Temperature Control is not perfect despite its many strengths.

Tuning complexity: Changing the parameters P, I and D requires expert knowledge, since improper tuning may lead to instabilities or inefficiency.

Noise Sensitivity: Outside noise and disturbances can impact the accuracy of the system.

Initial setup: Calibration and integration components require technical expertise.

The importance of understanding your system in detail is essential for maximum performance.

5. Application of PID Temperature Control

PID temperature control finds applications across various domains:

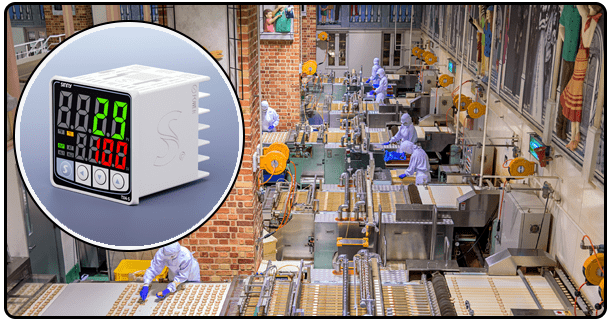

Industry Manufacturing: Controls the temperature of processes such as metalworking, plastic molding and chemical manufacturing.

HVAC System: HVAC systems maintain a constant temperature in the heating, ventilation and air-conditioning system.

Medical devices: Controls temperature in laboratory and incubator equipment.

Appliances for Consumers: Used to improve the user experience in ovens, thermostats and refrigerators.

The versatility and reliability PID controllers are demonstrated in these applications.

PID is the cornerstone for modern temperature regulation. The precision, energy-efficiency, and adaptability of this tool make it a valuable asset for many industries. Its advantages outweigh any limitations. We can expect to see further improvements in PID systems as technology advances, providing greater accessibility and efficiency.

- How is the PID temperature controller used? A Comprehensive Guide of Applications and Benefits

- What is a PID temperature controller? Features, advantages, and applications explained