How to Build a PID Temperature Controller: Components, Mechanisms, and Applications

Discover how PID temperature controllers work, including their components, control mechanisms, and applications. Learn about the importance of tuning for optimal performance.

Components Needed

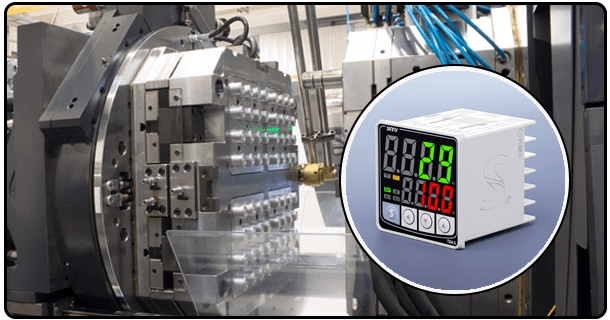

In order to assemble a PID temperature controller, the following items will be necessary.

* Microcontroller: Arduino boards offer simplicity of use with ample community support.

* Temperature Sensor: A thermocouple or thermistor can be used to accurately measure temperatures.

* Solid State Relay (SSR) or MOSFET: These components can be used to control heating elements.

* Heating Element: This could include anything from resistive heaters and induction heaters to any other suitable heating devices.

* Power Supply: Make sure that all components have access to reliable power sources for optimal functioning.

* Display (Optional): An LCD can be used to show both current temperature and setpoint on an interactive graph.

** Miscellaneous Components: Wires, resistors and connectors will also be required.

Understanding PID Control

PID control is an approach used to maintain an ideal setpoint by adjusting input control inputs. It consists of three parts, with proportional (P) output being directly proportional to current error value thus helping decrease overall errors.

* Integral (I): This component takes into account past mistakes and incorporates them over time so as to eliminate residual steady state errors.

* Derivative (D): This component predicts future errors based on rate-of-change trends, helping to dampen system response and curb overshoot.

Circuit Design

Establishing the Circuitrov When designing a circuit, its key elements include connecting temperature sensors to microcontrollers, heating elements through SSR or MOSFET switches and making sure there are adequate power supply connections. Below is an illustration showing such connections:

1. Connecting Temperature Sensor and Heating Element

Connect the temperature sensor to one of the analog input pins on the microcontroller.

2. Heating Element Connection mes

Connect heating element output of SSR or MOSFET that's controlled via digital output pin of microcontroller and control with digital pin number

3. Eventually

Power Supply: Make sure all components have their respective powers connected; typically the microcontroller should be powered either via USB or external power adapter.

Programming the Microcontroller

Once assembled, a microcontroller should be programmed with enough code to read temperature readings and implement PID algorithms, while controlling its heating element.

Here's an outline of this code:

1. Reading Temperature Sensor Data: To read temperature sensor data using an analog input.

2. PID Control Algorithm: Implement PID control algorithm and make necessary adjustments as part of PID algorithm implementation.

3. Ubertragung Of Sensor Reading Results To A PI Database System.

Control Output: Utilize your calculated PID output to control heating element via SSR or MOSFET.

4. Brightness Indicator (LED Displays are another great way of showing current temperature and setpoint on an LCD).

Assemble all components on either a breadboard or custom PCB.

Verify all connections are secure, and that all components have sufficient insulation against short circuiting.

Mount these in an enclosure if required to ensure safety and longevity of use.

Testing and Calibration

After installing your circuit, it's critical that it undergoes rigorous tests and calibration in order to achieve maximum effectiveness:

1.

Initial Testing: Power Up the system and check to make sure temperature readings are accurate.

2.

PID Tuning: Adjust P, I, D values manually or via software tools until optimal performance has been attained.

3.

When PID tuning has been accomplished successfully it should then be Time For Tuning (PTT). TLT can assist here too by optimizing P, I, and D constants so as to achieve maximum output...

Troubleshooting: Take steps to address issues related to reading errors, unstable controls or hardware malfunction.

Applications and Future Enhancements on PID Temperature Controllers

PID temperature controllers have numerous uses, such as incubators: maintaining stable temperatures to conduct biological studies.

* 3D Printers: Maintaining optimal temperatures on both print bed and extruder to maximize quality prints.

HVAC Systems: Regulating temperature through heating, ventilation and air conditioning systems.

Future upgrades could include adding remote monitoring features, connecting with IoT platforms or improving user interface features.

Conclusion

PID temperature controllers are essential devices that ensure precise temperature regulation across various applications. By understanding their components, control mechanisms and working principles we can gain greater insight into their importance for maintaining optimal performance and safety in temperature-sensitive environments. Tuning PID controllers correctly to achieve maximum effectiveness as well as extend longevity and ensure efficiency within any system is crucial in order to obtain maximum benefit and longevity of use.

- Building a Temperature Controller: Components, Mechanisms, and Applications

- How Temperature Controllers Work: Components, Types, and Application