How to Choose the Right Temperature Controller: A Comprehensive Guide

Learn how to choose the right temperature controller for your application. Explore different types, key factors, and advanced features to consider for optimal performance and efficiency.

Introduction

Temperature controllers are essential tools used across industries to achieve accurate temperature levels, making selection the right one crucial for optimal performance and efficiency. In this article we'll help guide your selection process among various types of temperature controllers while outlining key aspects and advanced features worth keeping an eye out for when making this important choice.

1. Understanding Temperature Controllers

Temperature controllers are devices designed to regulate temperatures by comparing an ideal setpoint against actual values and making adjustments as necessary in order to keep desired levels constant. They're essential when processes that depend upon precise control are underway.

Basic Types: There are different kinds of temperature controllers designed specifically to address various applications. Some examples are On/Off controllers, Proportional controllers and PID controllers - familiarizing yourself with these will allow for informed decisions when purchasing one of these instruments.

2. Key Considerations

Application Requirements: Before selecting a temperature controller for use in your application, carefully assess its specific needs in terms of precision, response time and the environment it will operate within.

Control Method: Temperature controllers come in various forms - digital, analog or PID. While digital controllers offer precise and complex application-focused control solutions, analog is more affordable while PID provides maximum accuracy and stability.

Sensor Compatibility: Make sure the temperature controller you are using is compatible with whatever kind of temperature sensor is being utilized - thermocouples or RTDs - in order to achieve accurate temperature measurement and control. Compatibility is vitally important.

3. Types of Temperature Controllers

On/Off Controllers: On/Off controllers provide an efficient yet cost-effective method of temperature regulation by switching their output on or off as soon as temperature crosses an established set point, ideal for applications where precise control over temperature is not essential.

Proportional Controllers: Proportional controllers continuously adjust output based on any deviation between set point and actual temperature, providing more stable temperature regulation while decreasing chances for temperature overshoot or undershoot.

PID Controllers: PID (Proportional-Integral-Derivative) controllers combine proportional with integral and derivative actions for precise temperature regulation, making these the go-to choice in applications needing precise temperature regulation. They offer excellent temperature stability.

Autotune PID Controllers: Autotuned PID controllers automatically adapt their parameters for optimal performance in dynamic environments where conditions change frequently, making these controls particularly helpful in providing stability over time.

Multiloop Controllers: Multiloop controllers offer precise temperature management across various temperature zones independently, making them suitable for complex applications where different areas require distinct temperature settings.

4. Advanced Features to Look Out for

Adaptive Control Algorithms: These algorithms allow temperature controllers to adapt their parameters automatically as conditions shift, thus guaranteeing optimal performance and stability even in dynamic environments.

Remote Monitoring and Control: Due to IoT/cloud integration, modern temperature controllers can now be monitored remotely, giving users the power to make real-time adjustments and assess performance from anywhere - further increasing convenience and efficiency.

Data Logging and Analysis: Advanced temperature controllers feature record logging features which enable detailed analyses and process improvements over time, providing opportunities to spot trends, diagnose problems and optimize processes. These functions are particularly helpful in spotting any resulting trends while improving processes overall.

Self-Tuning and Auto-Tuning: Temperature controllers with these features enable automatic adjustment to their settings for maximum performance, learning from experience as they go and making necessary changes as required, whereas auto-tuning controllers quickly set optimal parameters during initial setup.

5. Industry-Specific Considerations

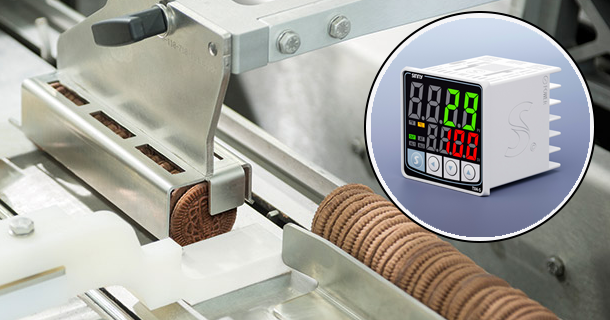

Manufacturing: For many manufacturing processes like plastic molding and metal treatment, consistent temperature regulation is of vital importance for product quality. Temperature controllers that maintain appropriate temperatures ensure high-quality outcomes for those processes.

Food Processing: Temperature control in food production and storage facilities is of critical importance in maintaining safety standards and guaranteeing product integrity and freshness. Advanced temperature controllers help keep temperatures within acceptable limits during processing and storage operations to minimize spoilage risk while adhering to safety protocols.

Pharmaceuticals: Temperature control in the pharmaceutical industry must adhere to stringent specifications in order to guarantee product efficacy and safety, making advanced temperature controllers essential in maintaining ideal production and storage temperatures, thus safeguarding product integrity.

HVAC Systems: Advanced temperature controllers enhance energy efficiency and comfort by maintaining precise temperatures in residential and commercial properties, helping maximize energy use while simultaneously improving indoor air quality. They serve to optimize energy consumption while optimizing life cycle costs and creating indoor comfort.

6. Making Your Final Choice

It is critical when purchasing a temperature controller to carefully weigh its costs versus benefits in relation to long-term savings, efficiency and product quality improvements.

Reputable Vendors with Excellent Support: When selecting vendors for temperature controller purchase and maintenance needs, choose those with proven records and exceptional support from customers. Reliable vendors provide valuable guidance in selecting and using temperature controls effectively.

Future-Proof Your System: When choosing a temperature controller, take into account future needs and upgrades as you make your selection. Look for controllers which are easily expandable or customizable according to future demands.

Conclusion

Selecting an efficient temperature controller is vital in order to maximize performance and efficiency in any application. By carefully considering your specific needs and features along with consulting experts on making informed choices that will enhance long-term operational efficiencies in your facility.

- How to Achieve Accurate Temperature Control in Your Processes: Tips & Techniques

- How Temperature Controllers Improve Operational Efficiency