How to Maintain and Calibrate Your Temperature Controller: A Comprehensive Guide

Maintaining and calibrating temperature controllers are integral parts of ensuring their optimal performance in industrial settings. Regular calibration helps maintain their precision.Industry experts report that regular maintenance can extend lifespan by as much as 50%; in this article,Sinny share temperature controllers maintain and calibrate guide, an authoritative resource covering every step in maintaining and calibrating them.

1. Understanding Temperature Controllers

Definition

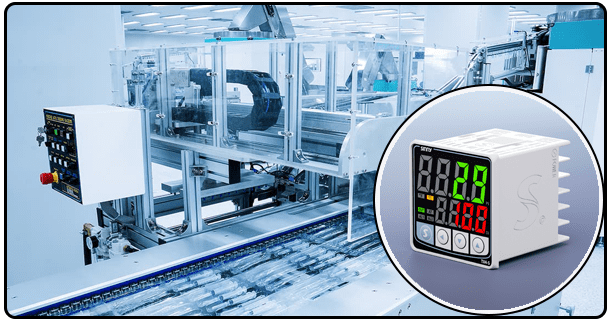

Temperature controllers are devices used to maintain consistent and precise temperature regulation within various industries. By receiving input from temperature sensors and controlling heating/cooling devices accordingly, temperature controllers ensure reliable temperature management and provide precise temperature regulation. These devices have become widely popular as a solution.

Key components of a temperature controller:

Sensors: Monitor actual temperatures.

Control Unit: processes sensor data and makes decisions based on an established temperature set point.

Actuators: Execute control actions by regulating heating or cooling devices accordingly.

Importance

Maintaining and calibrating temperature controllers are vitally important, ensuring they operate accurately and reliably - inaccurate temperature regulation could result in product defects, inefficient processes and increased operational costs that lead to further problems with operations costs and product yields.

2. Importance of Regular Maintenance

Longer Lifespan

Regular maintenance can substantially extend the lifespan of temperature controllers by identifying wear and tear early and correcting it in order to avert more serious problems that could potentially lead to equipment failure.

Enhanced Performance

Maintenance ensures temperature controllers operate optimally and consistently regulate temperatures to meet process-driven needs. Maintaining accurate temperature regulation is of utmost importance in many processes that rely on precise control for their success.

Preventive Maintenance

Preventive maintenance helps identify any potential problems before they escalate, which can save both time and money by avoiding unexpected downtime or costly repairs.

3. Steps for Maintaining Your Temperature Controller

Start Your Visual Examination

Conduct an in-depth visual inspection of the temperature controller to detect signs of wear, damage and corrosion on its components as well as loose wiring or damaged sensors that might indicate issues within it.

Cleaning

Clean the temperature controller regularly to remove dust, dirt, and debris. Use a soft cloth and, if necessary, a mild cleaning solution. Ensure that no moisture enters the device during cleaning.

Checking Electrical Connections

Inspect all electrical connections for corrosion to ensure they remain secure. Any loose or compromised connections could result in inaccurate readings and decreased performance, potentially decreasing performance while leading to inaccurate readings as a whole.

Keep Your Controller Up-to-Date

Make sure the software on the controller remains up-to-date; manufacturers often release updates which improve performance, fix bugs and add features - check manufacturer websites regularly for such announcements.

4. Understanding Calibration

Definition

Calibration is the practice of calibrating temperature controllers so their readings are as accurate as possible, by comparing its data against an established reference standard and making any required modifications.

Frequency

Calibration frequency depends upon individual applications and operating environments; generally speaking, temperature controllers should be calibrated annually or as specified by their manufacturers.

Calibration Standards

Calibration should adhere to industry-wide standards and guidelines, to ensure an accurate calibration process. These will guarantee uniform and repeatable measurements during calibration procedures.

5. Steps for Calibrating Your Temperature Controller

Preparation

Before calibrating a temperature controller, gather all necessary tools and create an ideal working environment - this includes having access to an accurate reference standard or calibration device, steady power source and controlled ambient temperature conditions.

Utilising a Reference Standard

Employ a reference standard or calibration device to accurately gauge actual temperature readings, then compare these readings against what your temperature controller displays. Ideally, any such reference standards must conform with national or international standards for traceability purposes.

Adjust the Controller

After performing your analysis, use either calibration software or manually adjust your temperature controller so its readings align with those from a reference standard. This may involve manually tweaking its controls unit itself.

Documentation

Document the calibration process and results. This includes recording the date, reference standard used, adjustments made, and final readings. Keeping detailed records helps track the performance of the temperature controller over time.

6. Common Issues and Troubleshooting

Inaccurate Readings

Inaccurate temperature readings can be caused by various factors, such as sensor drift, electrical interference, or software glitches. Regular calibration and maintenance can help identify and correct these issues.

Sensor Malfunction

Sensor malfunction can result in inaccurate readings. Check sensors for damage, loose connections or contamination before replacing any that appear faulty if necessary.

Software Glitches

Software glitches may lead to unpredictable behavior or inaccurate readings in controllers. If this issue continues, make sure the controller's software is up-to-date, reset it if necessary and contact its manufacturer for support if the problem remains.

7. Advanced Tips and Best Practices

Using Calibration Services

In some instances, professional calibration services may prove valuable in providing expert calibration and certification that ensure the highest degree of precision while adhering to industry standards.

Training Staff

Proper maintenance and calibration practices for temperature controllers is vitally important. Conduct regular training sessions to educate staff members on best practices.

Maintaining Records

Record-keeping can assist in keeping an accurate account of temperature controller performance, providing insight into trends, predicting failures and planning future maintenance activities.

8. Conclusion

Proper maintenance and calibration practices of temperature controllers are vitally important to their optimal performance and accuracy, and by following the steps outlined here you can extend their lifespan, improve their performance, avoid costly downtime, extend their useful lifespan as well as ensure smooth industrial processes run efficiently in the long run. Investing in preventive maintenance practices now will pay dividends later!

- Locating the Ideal Temperature Controller for Your Needs

- How to Install and Set Up a Temperature Controller: A Step-by-Step Guide