Locating the Ideal Temperature Controller for Your Needs

Selecting an effective temperature controller is paramount to ensuring optimal performance and efficiency in various industrial and commercial settings, How to choose an effective temperature controllers?including manufacturing, food processing and healthcare applications. Maintaining precise temperatures has significant effects on product quality as well as process reliability; therefore it is vitally important that when making this important choice you consider all relevant criteria with expert insight from credible references. This article provides tips for selecting an effective temperature controller.

1. Understanding Temperature Controllers

Definition

A temperature controller is an electronic device used to maintain and achieve an ideal environment within a system by monitoring current temperatures, comparing them against set points, and making adjustments as necessary to the heating or cooling mechanisms.

Types

There are various kinds of temperature controllers to meet various needs; each fits differently for specific applications: Click to temperature controllers catalog

On/Off Controllers: These controllers switch the heating or cooling device on or off to maintain the set temperature.

Proportional Controllers: These adjust the output power proportionally to the difference between the set point and the current temperature.

PID Controllers: These combine proportional, integral, and derivative control actions for highly accurate and stable temperature control.

Applications

Temperature controllers have applications across industries, from pharmaceuticals and food and beverage production, through electronics manufacturing and healthcare provision; where precise temperature regulation is of utmost importance. Click to temperature controllers solutions

2. Key Points to Keep in Mind

Accuracy and Precision

Temperature control requires accuracy and precision for success, with accuracy measuring how close readings from a controller match actual temperatures while precision refers to its ability to maintain stable conditions over time. High levels of both accuracy and precision are especially essential in processes requiring stringent temperature management such as semiconductor manufacturing.

Response Time

Response time refers to how quickly temperature controllers respond to changes. A fast response time is essential in fast-paced manufacturing environments in order to preserve product quality and maximize process efficiency.

Temperature Range

Your controller must match the needs of your application when choosing its temperature range. For instance, food processing operations often demand controlling both extreme high and extreme low temperatures at various stages of production.

Selecting an Appropriate Control Method

It is critical when purchasing a temperature controller to select an effective control method:

On/Off Control is suitable for simple applications in which precision is not critical, whilst Proportional Control offers more stable control for applications requiring moderate precision. PID Control, on the other hand, provides highly accurate and stable processes with complex processes requiring high levels of accuracy and stability.

A user-friendly interface is crucial to smooth operation and monitoring. Look for controllers with clear displays, intuitive controls and accessible programming features for optimal experience.

Compatibility

Before purchasing a temperature controller, ensure it will integrate smoothly with existing systems and sensors - failure to do so could result in inaccurate readings or ineffective temperature regulation.

Durability and Reliability

Durability and reliability are of utmost importance in industrial settings where temperature controllers may be exposed to harsh environments, so when choosing controllers it is vital that they can withstand these challenging environments with proven track records of reliability. Look for controllers which offer both robustness and proven dependability when selecting temperature controls for industrial settings

3. Types of Temperature Controllers

Mechanical Controllers

These physical mechanisms - bimetallic strips or liquid-filled bulbs, for instance - to regulate temperature are relatively straightforward yet fail to offer as much precision as electronic controllers do.

Electronic Controllers

Electronic temperature controllers utilize electronic components to measure, compare and regulate temperature with great accuracy and flexibility - perfect for use across a broad spectrum of applications.

Digital Controllers

Digital controllers are sophisticated electronic systems that utilize digital processing for precise temperature regulation. Many models include programmable settings, alarms and communication features making them the ideal solution for today's industrial applications.

4. Application-Specific Considerations

Manufacturing

Temperature controllers play an essential role in plastic molding, metalworking and semiconductor fabrication processes requiring precise temperature regulation - they ensure consistent product quality while decreasing waste production costs.

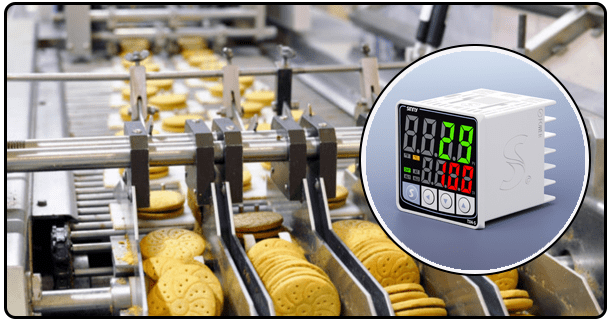

Temperature Regulation in Food and Beverage

In the food and beverage industry, temperature management is of critical importance in order to guarantee product quality and ensure consumer safety. Controllers maintain appropriate temperatures during processes like baking, pasteurization and refrigeration processes.

Healthcare

Temperature-control units play a vital role in healthcare environments by maintaining exact temperatures during storage and use of medical products like vaccines and pharmaceuticals. Temperature controllers ensure these supplies continue to work and be safe to use.

HVAC Systems

Heating, Ventilating, and Air Conditioning Systems In HVAC systems, choosing an effective temperature controller ensures energy-saving climate control at residential, commercial, or industrial buildings. Controllers help keep temperatures comfortable while optimizing energy consumption.

5. Budget and Cost Considerations

Initial Cost vs Long-Term Savings

Although initial costs should always be carefully evaluated when buying any temperature controller, long-term savings must also be evaluated carefully. A quality temperature controller will reduce energy use, lower maintenance expenses and enhance overall efficiency - an investment made now could pay dividends later!

Maintenance Costs

Regular maintenance is key to ensure temperature controllers perform at their best, so choose models with easy maintenance requirements and readily accessible replacement parts to cut downtime and repair expenses.

Energy Efficiency

Temperature controllers designed with energy-efficiency in mind can dramatically lower operating expenses. Look for models featuring features like energy-saving modes and efficiency ratings to maximize savings and lower expenses.

6. Top Brands and Models

Numerous leading temperature controller brands dominate the temperature controller market, often for their quality, reliability, and innovative features - such as Honeywell, Omron and Yokogawa to name just three of many examples.

Comparison of Popular Models When comparing popular models, take into consideration factors like accuracy, response time, user interface design and additional features like:

Honeywell UDC3200: Recognized for its versatility and dependability.

Omron E5CC: Equipped with advanced PID control features as well as an easy user interface. Yokogawa UT35A offers high precision with reliable performance for the ideal solution.

7. Installation and Setup

Installation Tips

Accurate installation is crucial to the efficient functioning of temperature controllers. Make sure all connections are secure and well configured as per manufacturer instructions for optimal functioning.

Calibration and Tuning

Calibration ensures the temperature controller provides accurate readings, making regular calibration essential in critical applications. Tuning, which applies primarily to PID controllers, involves making necessary changes in proportional, integral, and derivative settings until optimal performance can be reached.

Ongoing Maintenance

Regular maintenance, including cleaning, inspection, and calibration, is necessary to keep temperature controllers operating efficiently. Establish a maintenance schedule based on the manufacturer’s recommendations and the specific demands of your application.

8. Common Mistakes to Avoid

Overlooking Specifications

Overlooking specifications is one way of selecting an inappropriate temperature controller, so make sure the technical specs match up with your application needs before selecting your temperature controller.

Sensor Compatibility

Installing incorrect sensors may result in inaccurate temperature readings and poor performance, so be sure to confirm they work with your temperature controller of choice before purchasing any sensors.

Neglecting Calibration

Failing to regularly calibrate your temperature controller could result in inaccurate temperature regulation that negatively impacts product quality and process efficiency, so make calibration part of your regular maintenance regimen.

Conclusion

Finding an efficient temperature controller is critical to maintaining precise, efficient, and safe temperature regulation across a range of applications. By carefully considering factors like accuracy, response time, compatibility, cost and more when making this selection decision you will find one which perfectly satisfies your specific requirements - thus making this investment in temperature regulation worth its while!

- Temperature Controllers: Key Features and Benefits

- How to Maintain and Calibrate Your Temperature Controller: A Comprehensive Guide