How to Maintain Your PID Temperature Controller for Longevity

Discover the art of maintaining PID temperature controllers through this comprehensive guide. Please find out how regular inspection, calibration, and advanced diagnostics can extend their lives while guaranteeing process efficiency.

1. Introduction

Importance of Maintaining PID Temperature Controllers

PID (Proportional-Integral-Derivative) temperature controllers are critical in many industrial and commercial settings, providing precise temperature regulation at optimal performance levels. Regular upkeep can prevent unexpected failures while decreasing downtime for their associated processes, saving costs while increasing productivity overall. With that being said, understanding PID Temperature Controllers becomes key to effectively utilizing them and prolonging the longevity of these crucial pieces of machinery.

2. Understanding PID Temperature Controllers

Components of PID Temperature Controllers

PID temperature controllers consist of several essential elements that work together to achieve desired temperature settings, including:

Proportional Component: Adjusts output proportionately to current error magnitude to reduce it; integrate Component: Addresses past errors to eliminate steady-state errors.

Derivative Component: Predicts future errors based on rate of change, providing a dampening effect that minimizes overshoot and oscillations.

Sensors and Actuators: Measure temperature while performing control actions.

Control Algorithms and User Interfaces: Handle user data input while permitting interaction between them and the system.

3. Common Applications

PID temperature controllers have found widespread application across industries due to their precision and dependability; some such examples of their application include:

Industrial Processes:such as chemical manufacturing, where temperature control is critical to product quality.

HVAC Systems: Offering comfortable heating, ventilation, and air conditioning (HVAC).

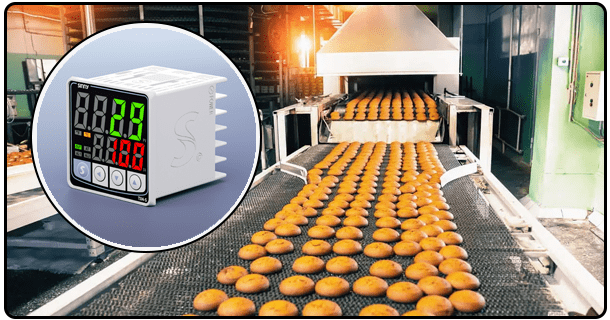

Food and Beverage Industries: Optimizing temperatures for cooking, pasteurization, and storage. Medical Equipment: Delivering accurate temperature regulation through incubators and sterilizers.

4. Best Practices for Maintaining PID Controllers.

Regular Inspection and Cleaning

Regular inspection and cleaning are vital to maintaining PID temperature controller performance and longevity. Visual inspections should be performed to identify physical damage or wear; dust can accumulate on sensors and components, affecting performance, so cleaning them using suitable materials is vital to keep these issues at bay. Furthermore, loose connections should be checked to ensure reliable operation.

Calibration for PID Temperature Controllers

Calibration is vital in maintaining the accuracy of PID temperature controllers. Over time, sensors and components may lose their original settings and become inaccurate measurements and control actions. Routine calibration—either annually or as required by the manufacturer—helps keep precision in check. Calibration usually involves comparing output against known standards to make necessary adjustments. Using tools or software specifically tailored for calibration can streamline this process and enhance accuracy.

5. Firmware and Software Updates

Maintaining PID temperature controllers on an ongoing basis requires staying current with firmware and software updates from manufacturers to maximize their performance and security. Manufacturers regularly release updates that fix bugs, introduce new features, and enhance security measures - it is therefore, PID temperature controllers must receive these enhancements and benefit from them as soon as they become available. To safely apply firmware or software upgrades, follow your manufacturer's instructions while backing up existing configurations before testing and updating (to ensure everything functions as intended after reboot).

Environmental Control

PID temperature controllers depend on an ideal operating environment to achieve long-term success, which means keeping their environment as stable and functional as possible. PID controllers are extremely sensitive to environmental elements like extreme temperatures, humidity levels, dust build-up, and electromagnetic interference. Therefore, ensuring their set environmental conditions are adhered to can prevent premature wear and failure. Utilize protective enclosures against dust and moisture buildup and set their loc with stable temperatures and minimal vibration levels to preserve both their integrity and functionality over time.

Preventive Maintenance Schedule

Establishing and adhering to a preventive maintenance schedule is one of the best ways of maintaining PID temperature controllers, with regular inspections, cleaning, calibration, firmware updates, log entries, or use of maintenance management software helping track past activities or identify trends or recurring problems. By adhering to such a schedule, potential issues can be detected early enough so they don't become an ongoing burden, maintaining continuous operation while guaranteeing the reliability of service provision. It may be wiser and cost-cutting for you as it will reduce maintenance expenses overall!

Troubleshooting Common Issues

Identifying Symptoms of Common Problems

Even with regular maintenance, issues with PID temperature controllers may arise that need attention. Common symptoms may include inconsistent temperature control, error messages and alarms, and unusual noises or vibrations. Early recognition can prevent more significant problems from arising; for instance, sensor drift could result from inconsistent temperature controls, while errors could indicate software or hardware malfunction.

Diagnostic Procedures

When troubleshooting PID temperature controllers, taking an organized approach is critical. You can start by consulting the controller's manual and any diagnostic tools provided by its manufacturer before moving through each of their potential causes step-by-step, beginning with loose connections or dirty sensors and working your way down through more complex causes, like loose wiring connections or dirty sensors. You may require tools like multimeters, oscilloscopes, or thermal imaging cameras to identify precisely which issues need to be addressed before turning back to either their manuals for solutions or manufacturer support resources for repairs once identified.

Advanced Maintenance Tips for PID Temperature Controllers

Using Advanced Diagnostic Tools

For more complex problems, advanced diagnostic tools provide valuable insights into the performance of PID temperature controllers. Thermal imaging cameras can identify hotspots indicating failed components or poor connections, oscilloscopes analyze signal integrity to reveal issues with electrical noise or degradation, and data loggers provide continuous monitoring that may allow uncovering intermittent issues not apparent upon one inspection visit.

Predictive Maintenance Technologies

Predictive maintenance utilizes data and advanced analytical tools to anticipate potential failures before they happen through techniques like vibration analysis, thermal analysis, and predictive maintenance software. Techniques such as vibration analysis can detect mechanical issues. Thermal analysis identifies overheated components, while predictive maintenance software uses algorithms to track trends and anticipate failures, allowing timely interventions before failure occurs.

Case Studies or Examples

Example 1: Industrial Process Control:

To optimize reaction rates and product quality at an industrial chemical processing plant, maintaining precise temperature control is vital. As part of their proactive maintenance schedule for PID temperature controllers - including regular calibration and environmental controls - to minimize downtime and maintain consistent product quality, advanced diagnostic tools were implemented as preventative maintenance practices proved their worth to production operations.

Example 2: HVAC Systems

A commercial HVAC system features PID temperature controllers to maintain comfort and energy efficiency within its building environment. Regular inspections, cleaning, and firmware updates were part of its maintenance routine. When users noted irregular temperature controls, systematic troubleshooting revealed a sensor had drifted out of calibration. Subsequent calibration rectified this problem and reinforced proper system functionality, emphasizing its importance.

6. Conclusion

Summary of Key Points

Maintaining PID temperature controllers involves regular inspection, cleaning, calibration, firmware updates, and environmental controls. Establishing a preventive maintenance schedule with advanced diagnostic tools can further extend their longevity and reliability while troubleshooting common issues and using predictive maintenance techniques to ensure optimal performance over time.

Final Thoughts

Proper maintenance of PID temperature controllers is vital to prolong their lifespan and ensure their reliable operation, from extended lifespan to enhanced productivity and operational excellence. By following best practices and taking advantage of recent advancements in diagnostic and predictive maintenance tools, businesses can maximize the benefits derived from their PID controllers - thus increasing productivity and efficiency and contributing towards operational excellence.

- Maximizing Output with PID Temperature Controllers

- Discover the Benefits of PID Temperature Controllers in Food Processing