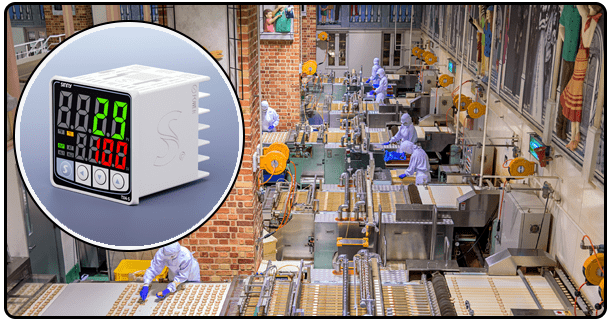

How to Set PID Values in a Temperature Controller: A Comprehensive Guide

Learn how to set PID values in a temperature controller with our detailed guide. Understand the roles of Proportional, Integral, and Derivative parameters, and follow step-by-step instructions for optimal temperature control.

1. PID Controllers

Proportional, Integral and Derivative controllers - more commonly referred to by their acronym PID - have become indispensable tools in various industrial and scientific settings, from temperature regulation to fluid dynamics applications. PID controllers use control inputs of systems to achieve setpoint control - in particular temperature regulation needs which require consistent thermal conditions requiring precise regulation from PID controllers.

2. Understanding PID Parameters

In order to achieve success with setting PID values, it is vital that one fully comprehends each parameter: their purpose and function are essential in selecting suitable values for PID systems.

Proportional (P):

This parameter establishes how we react to errors between our desired setpoint and current temperature; an increase in proportional gain will provide for stronger reactions against errors.

Integral (I):

The integral parameter addresses past errors by integrating their cumulative effects over time to help eliminate residual steady state errors.

Derivative (D):

This parameter anticipates future errors based on their rate of change, helping reduce overshoot while increasing system stability by damping response to unexpected signals.

3.Initial Setup

Before setting PID values, ensure the temperature controller and sensor have been installed and calibrated as planned. Follow these steps for initial setup:

Install the Temperature Controller:

To protect its performance from environmental influences that might interfere, ensure it is installed in an ideal locati0n and secured properly before adding power to it. Anschliessend, Install an Electronic Temperature Recorder

Connect the Sensor:

Once connected to a controller and placed in its proper area for temperature regulation purposes, place and connect a temperature sensor as part of its installation procedure. 3. Calibrate The Sensors: For accurate readings perform calibration to calibrate each temperature reading sensor individually.

Set Your Desired Temperature Setpoint:

Entering Your Target Temperature Into the Controller

4. Tuning the Proportional Gain (P)

Begin tuning by setting the integral and derivative gains to zero - this allows you to focus solely on tuning the proportional gain. Here's what to do next:

1Increase P Value Gradually increase proportional gain until oscillation begins in your system, an indicator that its gain might be too great.

Reduce P Value:

When oscillation begins, decrease proportional gain by about half to produce a stable response and avoid unwanted oscillation. This should provide for less instability over time.

5. Tuning Integral Gain (I)

Once the proportional gain has been adjusted, next comes tuning the integral gain, or "I." Tuning this feature helps eliminate steady-state errors; here is how it should be accomplished:

Its Increase I Value:

Gradually increase the integral gain while monitoring system response in order to eliminate any residual error.

Avoid Oscillations:

If oscillation occurs excessively, lower integral gain slightly until stability can be attained in response.

Tuning Derivative Gain (D) Once all components have been calibrated and tested successfully, the final step should be tuning the derivative gain (D). Aim to adjust your derivative gain in such a way that reduces overshoot while improving system stability - follow these steps!

Wiggle the D Value Upward:

Gradually increase the derivative gain while monitoring system behavior to reduce any oscillations and enhance stability. The goal should be to eliminate oscillations while improving stability.

Adjust for Balance:

Adjust the derivative gain until a balance between responsiveness and stability has been found - too much derivative gain may lead to slow responses and can even stall an engine entirely!

6. Testing and Validation

After tuning PID values, it's vitally important to perform thorough system validation tests under various environmental conditions to ensure consistent performance of your system. Here's a checklist to guide testing and validation:

Benchmark Across Different Setpoints:

Conduct tests at various setpoints and observe its behavior to make sure temperature remains within desired parameters. 2. Final Adjustments: As needed, make minor modifications to PID values so as to fine-tune system performance and achieve best performance from system.

7.Common Challenges and Troubleshooting

Tuning PID controllers may present multiple challenges. Below are some issues and troubleshooting tips you might come across:

If the system exceeds its setpoint, reduce proportional or integral gain accordingly.

Oscillations:

Excessive oscillations may be controlled by decreasing proportional/integral gain and increasing derivative gain.

Slow Response:

If your system is responding too slowly, increase proportional gain or reduce derivative gain to improve system response times.

8.Conclusion

Setting PID values in a temperature controller requires a systematic approach and an understanding of each parameter's role. By following the outlined steps and making necessary adjustments, you can achieve precise and stable temperature control. Regular testing and validation are essential to ensure optimal performance under varying conditions.

- How to Connect a PT100 to a Temperature Controller: A Detailed Guide

- How to Connect a Thermocouple to a Temperature Controller: Step-by-Step Guide