How To Tune A Temperature Pid Controller?

Welcome to the world of precise control with our expert guide on tuning temperature PID controllers! Learn to fine-tune P, I, and D parameters for an evenly balanced system.

1. Introduction

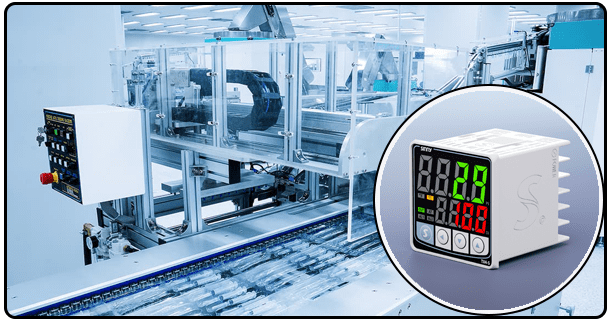

PID controllers have long been revered in temperature automation as the go-to choice, offering impressive levels of precision while remaining simple for users to utilize. But even sophisticated equipment requires fine-tuning to achieve peak performance—this article explores all aspects of tuning PID temperature controllers so your system runs efficiently and without glitches.

Understanding PID Parameters

At the core of PID tuning lies an understanding of all three parameters:

* Proportional (P): This variable adjusts output proportionally to current errors in temperature data. It serves as the initial line of defence against temperature discrepancies.

* Integral (I): This parameter addresses past errors by providing corrective forces to eliminate steady-state mistakes over time.

* Derivative (D): Derivative control identifies future errors by considering rate-of-change data and smoothens out system responses accordingly.

Preparing to Tune

Before initiating any tuning process, it is critical that both mechanically sound systems and well-installed and configured PID controllers exist and function optimally - this forms the cornerstone for an effective tuning experience.

Establishing Initial PID Values Step one in optimizing tuning starts by setting initial values for P, I, and D:

* Start by setting I and D values at zero before increasing P until your system begins oscillating. Then, dial back your initial setting until your system stabilizes again.

* To improve steady-state error without inducing instability, modify the Integral value to achieve optimal reduction.

* To avoid overshooting and enhance system responsiveness, apply derivative values cautiously to avoid exceeding the threshold.

Tuning Process

Tuning a PID controller can be an iterative process: it could involve tweaking several times until the desired output occurs.

1. mes To begin tuning manually, make small adjustments and observe their effects.

2. For autotuning features available to you, establish an initial point for further refining sound quality.

2. Testing and Observation

With initial values set, now comes time for some real testing:

* Monitor how your system reacts to temperature variations

* Gradually adjust PID values until a balance between responsiveness and stability has struck.

Fine Tuning Performance Tune Your System For Peak Results Finer tuning for optimal performance requires artistic expression:

* Adjust PID values until they quickly and consistently reach setpoint without excessive overshoot or other delays.

* You should anticipate that different systems require individual tuning strategies. Be prepared to adapt your approach according to what best suits the system.

Common Issues and Troubleshooting

Problems may still arise with proper tuning: * If the temperature begins fluctuating dramatically, revisit both Proportional and Derivative settings for possible adjustment.

* If your setpoint is offset, an Integral adjustment could be the appropriate course of action.

* When in doubt, professional assistance may provide fresh perspectives.

Maintenance and Checkups

A PID controller should neverCheckupsotten about, it requires regular attention for maximum effectiveness and optimal performance. Routine check-ups ensure long-term performancecheckupsrming regular checks allows us to identify issues before they negatively impact the system.

Related product links

- Mastering Precision: Advanced PID Temperature Control Systems

- What Is The Difference Between Analog And Digital Temperature Controllers?