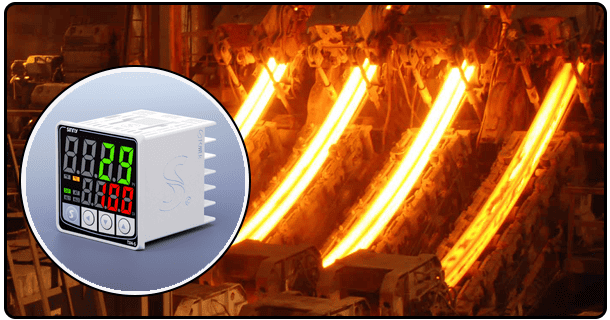

Mastering Precision: Advanced PID Temperature Control Systems

Dive deeper into temperature regulation with our comprehensive look at PID controllers - proportional, integral, and derivative controls that work harmoniously to deliver top performance for industrial automation systems.

Proportional-Integral-Derivative, or PID control, is an elegant feedback mechanism that constantly adjusts process variables until they reach an exact setpoint set by its mastermind—like an orchestra conducted by its conductor—creating harmony between response and stability of control systems.

Proportional Control as the Foundation of Responsiveness

Proportional control forms the backbone of responsiveness within PID controllers by being the initial response mechanism when there is a discrepancy between the actual temperature and setpoint temperature; when this discrepancy arises, it adjusts output directly in proportion with it to maintain the harmony of the production versus error ratios.

1. Integral Control: Pursuit of Perfection

Integral control is the result of the PID controller's cumulative wisdom. It takes into account past errors as part of its corrective force to make the desired process variable consistently reach its setpoint and remain there over time. It attempts to correct for persistent discrepancies while working towards reaching and remaining at the setpoint values of process variables.

Derivative Control: Anticipating the Future

Derivative control is the precursor of PID control. By tracking error rate changes and anticipating behavior, derivative control provides early warning of overshoot and ensures a rapid return to equilibrium. This anticipatory action avoids costly overshoot and brings a swift return to equilibrium.

2. Temperature Regulation with PID Controllers

PID controllers stand alone regarding temperature regulation: they're virtually unmatched at maintaining desired thermal conditions by reading signals from sensors such as thermocouples or RTDs and making adjustments accordingly, keeping to the setpoint.

Advantages of PID Temperatutos

PID controllers offer unrivaled precision and stability, making them the goresponsece in temperature-dependent processes that must always always remain accurate. Furthermore, their adaptability to shifting conditions makes them essential tools in contemporary industrial applications.

Closed Loop Systems: Harmony in Action

A closed-loop system embodies self-regulation by having its output directly influence its operation toward reaching desired goals. A PID-controlled system utilizes sensors for output detection and sensing control units for deviation computation before an actuator provides corrections accordingly.

Tuning of PID Controllers: Integrating Art and Science

Tuning a PID controller is like fine-tuning an instrument: setting the optimal gains for proportional, integral, and derivative terms to achieve peak performance is paramount; improper settings could cause instability and inefficiency.

Types of PID Controllers: Versatility in Form

PID controllers come in many forms, from standalone units that serve simple processes to sophisticated PLC integration controllers capable of complex automation tasks. Your selection should depend upon both the complexity of your process and desired integration levels.

Historical Context and Development

PID control dates back to the 17th-century centrifugal governor, though formal PID controllers were not widely implemented until 20th-century visionaries such as Nicolas Minorsky began designing them systematically.

3. Modern Application of PID Controllers

Today, PID controllers have become an essential element in industrial automation. They are known for their reliability and user friendliness across various industries, all of which provide precise process control that drives success and efficiency.

4. Conclusion

An Essential Component of Industrial Automation Temperature PID controllers are unheralded heroes of industrial automation, ushering in an age of precision, stability, and efficiency in industry control systems. As industries advance with more complex needs for process management systems, PID controllers remain key instruments of process control, and their importance continues to expand alongside their applications in process control applications.

Related product links

- Temperature PID Controllers: Ensuring Precision in Process Control

- How To Tune A Temperature Pid Controller?