Integrating Temperature Controllers Into Your System

Discover how integrating temperature controllers can enhance operational efficiencies, product quality, energy savings and operational expenses savings while saving costs through operational expenses savings. Understand all necessary steps, advanced techniques and industry considerations necessary for successful integration.

Introduction

Temperature controllers are increasingly being integrated into various industries' existing systems in order to precisely maintain specific temperatures, improving operational efficiencies, product quality and energy savings. This article presents all steps and considerations of successfully incorporating temperature controllers.

1. Understanding Temperature Controllers

Definition and Function:

Temperature controllers perform two key functions. First, they compare an expected setpoint temperature against actual ambient conditions to make necessary adjustments that maintain desired levels. These devices are particularly crucial when used for processes requiring precise temperature stability such as manufacturing operations.

Types of Temperature Controllers: There are various kinds of temperature controllers designed for specific uses, with On/Off Controllers, Proportional Controllers and PID Controlers among them as some of the primary models available. Understanding each one will assist individuals in selecting an apt model according to individual needs.

2. Preparing for Integration

Evaluate System Requirements:Before installing a temperature controller into any system, the initial step must involve an assessment of system requirements. Take into consideration factors like precision requirements, response times and operating environments of potential controllers before beginning their integration process.

Select an Appropriate Temperature Controller: Select an ideal temperature controller based on the requirements of your system, such as whether PID controllers would serve better for applications requiring high precision and stability, or whether simpler applications might suffice using On/Off controllers instead.

Compatibility Check: Before purchasing any temperature controller, always ensure it will function with existing sensors and actuators to achieve accurate temperature measurement and regulation. Compatibility plays an integral part in providing precise temperature readings and regulation.

3. Installation Steps

Proper installation of temperature controllers is crucial to their successful use and functionality. Always adhere to manufacturer specifications when setting them up, making sure all connections are secure and configured according to specifications.

Configuration: Once installed, set up your controller so it runs at its best by configuring its temperature range, control mode and any additional features relevant to you.

Calibrating Your Temperature Controller to Accuracy: Use known standards as benchmarks when calibrating the temperature controller so it accurately reads temperatures; make any needed changes so the readings line up with what should happen and adjust as necessary until everything aligns perfectly.

4. Advanced Integration Techniques

Remote Monitoring and Control: Modern temperature controllers equipped with IoT/cloud technologies offer users remote monitoring and control features, giving real time adjustments possible as well as performance measurements anywhere for convenience and efficiency in use. With these remote capabilities comes real-time adjustments as well as monitoring capability from anywhere allowing real time adjustments as well as performance measurements from anywhere for ultimate convenience and efficiency in use. This feature makes real time adjustments possible creating maximum convenience and efficiency of use - creating maximum convenience and efficiency in use!

Data Logging and Analysis: Temperature controllers equipped with data logging features allow temperature data to be captured over time for further examination to identify trends, diagnose problems and optimize processes resulting in improved efficiency and performance.

Self-Tuning and Auto-Tuning: Integrating self-tuning and auto-tuning features into temperature controllers can significantly enhance their performance, adapting as necessary with experience while setting optimal parameters more quickly when first setup is underway.

5. Industry-Specific Considerations

Manufacturing: Temperature controls play an invaluable role in assuring product quality for manufacturing operations such as plastic molding, metal treatment and electronics assembly. They help maintain consistent temperatures to minimize defects while simultaneously improving efficiency.

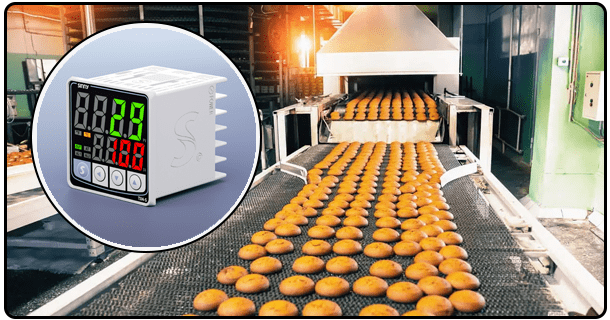

Food & Beverage: Temperature regulation in food and beverage manufacturing industries is of vital importance in terms of maintaining safety and quality - this applies to pasteurization, fermentation and refrigeration storage processes as well as pasteurisation; temperature regulators play an invaluable role here! Temperature controllers play an integral part in meeting compliance standards by maintaining temperatures required to prevent spoilage as well as comply with them; their role can only increase! Temperature controllers play an essential part!

Pharmaceuticals: Temperature control is critical in protecting product efficacy and safety for pharmaceutical manufacturers and distributors. Temperature controllers play an indispensable role during production, storage and transport to create optimal conditions that preserve both integrity and effectiveness of temperature-sensitive drugs that need special consideration when temperature needs must be maintained in storage conditions or transit conditions.

Temperature Controllers Improve HVAC Systems: Temperature controllers increase energy efficiency and comfort in HVAC systems by maintaining consistent temperatures across residential and commercial properties, optimizing energy use and creating an enjoyable indoor air quality experience for customers.

6. Troubleshooting and Maintenance

For optimal temperature controller performance, swiftly identifying and solving integration issues promptly is of vital importance in keeping them running at maximum efficiency. These may range from incorrect configuration, malfunctions in sensors or communication errors - to incorrect sensor placement on temperature probes leading to false readings - among many other sources of concern. By performing regular system inspections you can more quickly spot potential problems more efficiently and address them more promptly.

Regular Maintenance: Preserving the long-term performance of temperature controllers requires regular maintenance to prevent unexpected failures and extend its lifespan. A maintenance schedule can help avoid unexpected breakdowns while prolonging equipment longevity. Cleaning sensors, checking connections, and recalibration should all be part of this regiment of regular upkeep.

Upgrades and Future-Proofing: It is of utmost importance that temperature controllers continue functioning effectively for their intended purposes. Staying abreast of emerging technologies enables you to make educated decisions when upgrading or replacing them, such as upgrades vs replacements.

7. Conclusion

Integrating temperature controllers into your system can dramatically enhance operational efficiency, product quality and energy savings. By understanding your specific system needs and selecting an ideal controller that complies with best practices for installation, configuration and maintenance; optimal performance can be reached and long-term success secured. Consulting experts as well as taking advantage of advanced features can further optimize temperature regulation to help guarantee operational success is realized.