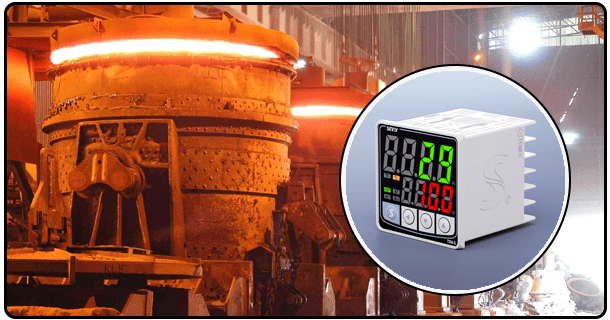

PID Temperature Controllers: Enhancing Safety and Reliability

Enter the world of PID temperature controllers, which play an essential role in maintaining safety and reliability within industrial processes. Explore their sophistication as tools that prevent system failures while offering consistent performance - revolutionizing temperature regulation!

1. Introduction

PID Temperature Controllers

Proportional, Integral and Derivative (PID) controllers are advanced devices designed to regulate temperatures with great precision. Utilizing an intelligent algorithm that continuously calculates an error value - defined as the difference between desired setpoint and actual process variable values - PID controllers use this data to make adjustments that bring process variable closer toward its ideal setpoint value.

PID Controllers' Key Role

PID controllers play an essential part in improving safety and reliability across numerous industries. By maintaining precise temperature regulation, they help prevent system failures while assuring consistent product quality - something their ability to minimize temperature fluctuations greatly assists when dealing with processes requiring high accuracy or stability.

2. The Science of PID Control

Explanation of the PID Control Algorithm

The PID control algorithm consists of three components:

Proportional (P): This component generates output that relates directly to current error levels and provides immediate reaction when temperature shifts occur.

Integral (I): This component integrates errors over time in order to eliminate any residual steady state errors that might remain after temperature adjustments have taken effect.

Derivative (D): This component forecasts future errors by taking into account their rate of increase; adding damping effect for optimal system stability.

PID Controllers Contribute to System Safety and Reliability

PID controllers increase system safety and reliability by providing precise temperature regulation. Their proportional component quickly addresses deviations while integral and derivative components correct errors accumulated over time while the derivative prevents overshooting; all three combined create an accurate temperature system which significantly decreases risks related to process failure or accidents.

3. Safety Enhancements with PID Controllers

PID controllers play an invaluable role in protecting systems against failures and accidents by maintaining consistent temperatures that protect equipment against overheating or freezing, which could otherwise lead to equipment damage or hazardous situations. Their fast response times ensure the system operates within safe operational limits.

Case Studies Illustrating Safety Improvements

Chemical Processing: One chemical plant utilized PID controllers to help them maintain reaction temperatures, leading to reduced thermal runaway incidents and improvements overall safety.

Food and Beverage Processing Facilities: An upgrade in PID controllers allowed food processing facilities to more consistently cook temperatures while decreasing risks related to foodborne illness.

4. Reliability in Temperature Control

PID controllers have become known for their consistent performance over extended periods. Their continuous temperature adjustment capabilities guarantee that temperatures stay constant even under fluctuating environmental conditions - essential features in processes requiring long-term stability.

Pharmaceutical Manufacturing: When temperature control is of vital importance for product quality, PID controllers have proven their reliability by maintaining consistent conditions despite external temperature variations.

5. Advanced PID Features to Promote Safety and Reliability

Modern PID controllers include advanced features like auto-tuning and fault detection to maximize performance and detect issues before they escalate further. Auto-tuning will adjust PID parameters automatically for optimal results while fault detection alerts operators of potential issues before they arise.

Benefits of Advanced Features

Advanced features significantly enhance safety and reliability in critical applications. Auto-tuning ensures optimal controller operation to minimize temperature deviation risks; fault detection provides for proactive maintenance that prevents unexpected failures to minimize downtime.

6. Implementing PID Controllers for Enhanced Safety

Best Practices for Integration Integrating PID controllers into existing systems requires careful consideration and implementation; best practices could include:

System Evaluation: Evaluate your current system to make sure it can accommodate PID controllers installed or reconfigured with PID technology.

Documentation: Document the installation/configuration process as it takes place.

Testing: Perform rigorous tests of new controllers to make sure they work as intended.

Training and Resources

Proper training and resources are indispensable when it comes to operating and maintaining PID controllers safely and successfully. By providing operators with extensive instruction in using and troubleshooting PID controllers, proper system administration becomes possible and any issues or disruptions can be dealt with swiftly and appropriately.

7. Regulatory Compliance and PID Controllers

There are various industry standards related to temperature control such as ISO and ANSI that must be observed for safe operations and quality results. Adherence with these regulations ensures both quality assurance and ensured safety standards for operations.

PID Controllers as an Effective Way of Meeting Regulatory Requirements

PID controllers enable industries to meet regulatory requirements by offering precise temperature regulation. Their consistent temperature setting helps processes adhere to rigorous safety and quality standards while decreasing risks related to regulatory violations.

8. Future of PID Temperature Control Systems

Emerging Trends and Technologies

PID temperature control technology continues to advance at an incredible rate, as innovative new trends like machine learning and Internet of Things integration become part of its capabilities. PID controllers now incorporate these innovations to increase accuracy and adaptability while remaining cost effective for consumers.

Potential Effect on Safety and Reliability Standards

Advancements can have a dramatic effect on safety and reliability standards. Improved data analytics and predictive maintenance tools could allow more precise temperature regulation as well as earlier detection of issues, helping ensure processes run safely.

9. Conclusion

PID temperature controllers play an invaluable role in assuring safety and reliability across various industries, providing precise yet stable temperature regulation to reduce risks of system failure while increasing overall process efficiencies.

Final Considerations on PID Technology Development

As PID technology evolves, its role in industrial automation will only become more significant. New features and emerging technologies will only increase its capabilities further - becoming indispensable tools for maintaining safety and reliability during temperature-sensitive processes.

- Real-World Applications of PID Temperature Control

- Implementing PID Temperature Control in Existing Systems