Seamless Integration of PID Controllers with PLC Systems

Venture into industrial automation with our guide on integrating PID temperature controllers and PLC systems for maximum precision and efficiency in your processes.

1. Introduction

PID temperature controller integration with PLC systems exemplifies industrial automation's unique partnership of precision and programmability, creating systems which not only meet but surpass modern industry demands for robust responsiveness. This article seeks to illuminate this path to seamless integration so as to produce results which remain robust yet dynamically responsive systems.

2. PID Control and PLC System Fundamentals

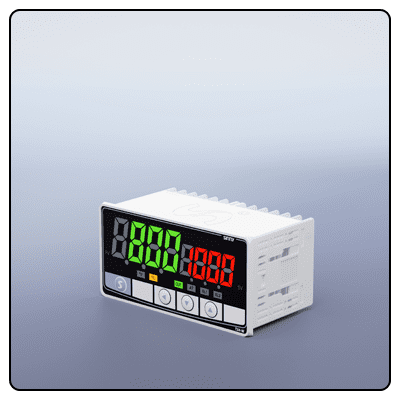

At the core of this integration lies a PID controller - an instrument which implements Proportional, Integral and Derivative principles to maintain an exact temperature - while PLC (Programmable Logic Controller) serves as its brain. Through logic programming it executes complex sequences of actions efficiently.

3. Planning for Integration

Before merging PID controllers and PLC systems together can commence, one must collect all required components and ensure compatibility between them - much like setting the stage for an important performance where each actor needs to know his cues and lines.

* Components: This ensemble comprises the PID controller, PLC, sensors and actuators as well as a communication interface.

* Compatibility: Ensuring effective communication between PID controller and PLC is of utmost importance, including verifying communication protocols and electrical standards that both devices support.

4. Step by Step Integration Process

Once preparations have been concluded, the integration process begins in stages:

1. Connection: When first setting up, connect the PID controller physically to the PLC by wiring its outputs directly into its inputs on both ends. This step often includes cutting some wires out from between controller outputs and PLC inputs and vice versa for ease of wiring and testing purposes.

2. Configuration: Set your PLC up so it recognizes and communicates with the PID controller by configuring I/O addresses and parameters within its software environment.

3. Programming: Once programming of the PLC has taken place, its logic for PID control needs to be included within its code in order to facilitate PID functions or algorithms. This may involve writing or altering its code directly in order to achieve optimal PID control performance.

4.Testing: Before full-scale deployment, perform extensive system tests on your integrated solution to make sure it performs as intended and detect any issues before they have an effect on larger processes. Performing regular checks ensures you catch any potential hiccups before they have an adverse impact.

5. Programming the PLC for PID Control

Programming a PLC to manage a PID controller requires both logic and precision. The software of a PLC serves as the canvas upon which PID control logic can be painted using languages like Ladder Logic, Function Block or Structured Text.

* PID Function Blocks: Many PLCs include pre-built PID function blocks which can easily be customized for your process, making programming much simpler with drag-and-drop control logic assembly. These function blocks help make life simpler during implementation of automation technology projects.

* Custom Programming: When required for unique applications, custom programming may be essential. This involves writing the PID algorithm within a PLC's programming environment in such a manner as to meet all specific temperature control process needs.

6. Tuning and Calibration

Once a PLC has been programmed, its system needs to be adjusted and calibrated so the PID controller works effectively.

* Tuning: Tuning involves fine-tuning PID parameters within a PLC program to modify its response to changes in temperature.

* Calibration: Ensuring sensors and actuators respond accurately to PLC commands is of utmost importance, which necessitates calibration as this ensures physical reality aligns with programmed expectations, guaranteeing system success.

7. Testing and Troubleshooting

Once programmed and tuned, testing an integrated PID and PLC system is essential to its proper function under any circumstance. This stage ensures that its operation operates according to design.

* Simulation: Conduct simulations to measure how your system reacts to temperature variations and identify any inconsistencies with its behavior - for instance if there are discrepancies with PID controller. This helps identify any discrepancies.

* Live Testing: Implement the system into a real world scenario to observe its performance and make necessary modifications for optimal operation of the system. Make any necessary alterations as required for effective system performance.

Troubleshooting is an ongoing task; common issues include communication errors between PID controller and PLC or inaccurate temperature readings - often these problems can be resolved by reviewing system configuration and calibration settings.

8. Advanced Integration Concepts

PID controllers and PLC systems can be enhanced through advanced concepts:

* IoT Integration: Integrating IoT capabilities allows for remote monitoring and control of PID controller via PLC for increased flexibility and responsiveness.

* Industry 4.0: Utilize Industry 4.0 principles to implement intelligent systems capable of adapting over time, increasing efficiency and productivity.

9. Case Studies

Exploring real world applications provides invaluable insight into integrating PID temperature controllers and PLC systems.

* Automotive Industry: One carmaker employs PID controllers with PLCs in tandem to manage the curing process for coatings on every vehicle for flawless finishes.

* Pharmaceuticals: Precise temperature regulation is of critical importance in pharmaceutical plants. Integrating PID controllers and PLCs ensure that medications produced meet stringent quality and safety criteria to guarantee efficacy and safety for patient use.

These case studies illustrate the transformative power of integration, showing its positive results on accuracy, efficiency and product quality.

10. Conclusion

Integrating PID temperature controllers and PLC systems together represents an exciting milestone towards industrial automation's future. This guide has illuminated a path towards such integration, offering guidance to those beginning this journey. As technology develops further, more intricate integrations may emerge - potentially producing systems with unprecedented programmability that guarantee efficiency in production processes.

- Selecting the Ideal PID Controller Optimize Your System's Efficiency

- Maximizing Quality with PID Temperature Controllers | Precise Process Regulation