Temperature Controllers Provide Advanced Features

Discover the advanced features of temperature controllers, such as adaptive control algorithms, remote monitoring and multi-zone control. Discover how these innovations increase efficiency, product quality and energy savings across industries.

1. Introduction

Temperature controllers have become an invaluable asset across industries for providing precise temperatures with advanced features that meet today's expanding application demands. Here we explore their advancements while emphasizing their significance and value.

2. Types of Temperature Controllers

On/Off Controllers:

These cost-effective temperature regulators offer simple yet cost-efficient temperature regulation solutions by switching off when temperatures surpass an arbitrary set point, making them suitable for applications where precise control isn't essential.

Proportional Controllers:

As opposed to on/off controllers, proportional controllers provide more stable temperature regulation by continually adapting output in response to fluctuations between set point temperature and actual temperature; decreasing overshoot or undershoot issues while providing greater temperature stability regulation.

PID Controllers:

PID (Proportional-Integral-Derivative) controllers are one of the most sophisticated types. By combining proportional control with integral and derivative actions, these sophisticated units deliver precise temperature regulation - ideal for applications which demand such tight regulation.

3. Key Advanced Features

Adaptive Control Algorithms (ACAs):

These advanced features of temperature controllers enable dynamic adaptation of their control parameters according to changing environmental conditions for maximum performance and stability even in dynamic environments.

Remote Monitoring and Control:

Modern temperature controllers equipped with IoT/cloud technologies enable remote monitoring and control capabilities, giving users real-time adjustments as well as performance tracking anywhere - providing greater convenience while cutting costs simultaneously.

Self-Tuning and Auto-Tuning:

Temperature controllers equipped with self-tuning capabilities automatically adapt their settings for optimal performance, learning from experience to make necessary changes as they go; auto-tuning controllers allow quick setup with optimal parameters right off the bat.

Data Logging and Analysis:

Advanced temperature controllers include features to log temperature data over time for analysis and process improvement purposes, including trend identification or diagnosing issues to optimize processes. This feature can prove especially valuable in helping spot trends or optimize processes.

Multi-Zone Control:

Utilizing this feature of temperature controllers, they can efficiently oversee multiple temperature zones separately; making this feature particularly helpful when different areas require specific temperature settings for manufacturing or HVAC systems.

4. Applications in Multiple Industries

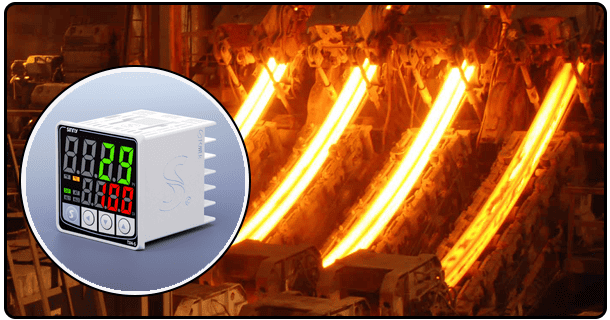

Manufacturing:

Temperature controllers play a vital role in processes like plastic molding and metal treatment where proper temperature regulation is key to product quality.

Food Processing:

Precise temperature control is integral to food safety and quality in the food industry, and advanced temperature controllers help ensure ideal processing temperatures during production and storage.

Pharmaceuticals:

Pharmaceutical manufacturers depend upon tight temperature regulation in order to guarantee product efficacy and safety; advanced temperature controllers provide optimal production and storage conditions.

HVAC Systems:

When it comes to HVAC systems, advanced temperature controllers offer considerable benefits in energy savings and comfort by maintaining consistent temperatures across homes and offices alike.

5. Advantages of Advanced Temperature Controllers

Enhance Process Efficiency:

Advanced temperature controllers' precision temperature regulation can greatly boost process efficiencies by cutting back on wasteful activities and increasing productivity.

Improve Product Quality:

Precise temperature controls ensure higher-quality outcomes that ensure reliability for customers.

Energy Savings:

Modern temperature controllers enable their users to significantly cut energy use by setting optimal temperatures that result in greater savings on utility costs.

Reduce Downtime:

By employing advanced diagnostics and predictive maintenance features, advanced features can significantly decrease unexpected breakdowns while simultaneously cutting both downtime and maintenance costs significantly.

6. Future Trends

Temperature controllers have an exciting future ahead as AI/ML becomes an invaluable resource in predictive control, maintenance and reliability enhancements. AI algorithms in temperature controllers promise greater performance and dependability for clients alike. This trend represents great promise as temperature controllers adapt their AI algorithms for improved client services and increased performance and dependability.

Future Temperature Controllers will Offer User-Friendly Interfaces: Future temperature controllers will offer more user-friendly user interfaces to make controlling and monitoring temperature systems simpler for any individual.

Sustainability Priorities: Environmental impact management has become one of the primary goals in line with global sustainability objectives, driving innovative companies like BoscoTemp to design eco-friendly temperature controllers to minimize its ecological footprint and support their global goals for sustainability.

7. Conclusion

Temperature controllers play an essential part in improving process efficiencies, product quality and energy savings across numerous industries. With technological progress bringing AI, user interface improvements and sustainability-centric innovation features into this space - further advancement in this realm of innovation will only accelerate.

- The Importance of Temperature Controllers in Research and Development

- Temperature Controllers in Industries: A Comprehensive Overview