The "Comprehensive guide to tuning P and I gains in temperature PID controllerS

Discover the basics of P-I gains for temperature PID controllers. This expert guide will show you how to adjust gains for precise control, and also explore the real-world application of these gains.

1. Understand P and I Gains

Proportional gain (P) The parameter that determines how the controller will respond to an error. Higher P gains result in faster system response but can cause instability and overshoot.

I Gain: This gain is a measure of the cumulative errors that have been made over time. It ensures the system reaches its setpoint. Nevertheless, an excessive amount of I gain can lead to oscillations and a sluggish response.

Both gains are used in conjunction, the P gain providing an immediate correction while the I gain eliminates residual errors. A stable control system requires a balance between these two gains.

2. The Effects of P-I Gains on Temperature Control

You can summarize the influence of P-I gains on temperature regulation as follows:

High Gain: Quick responses to temperature changes; it may cause oscillations and overshoot if the gain is set too high.

Reduced P gain: Slowed system response, but better stability

High Gain I: Efficient in reducing steady state errors, but can result in settling time and oscillations.

Low Gain: Limited capability to correct persisting errors leading to minor discrepancies when maintaining temperature.

In a system for controlling temperature, for example, an improperly-tuned P gain may lead to temperature fluctuations that are rapid, while excessive I gains could result in prolonged recovery time after disturbances.

3. Tuning P and I Gains

For optimal temperature control, it is essential to tune P and I gain effectively. For this, there are several methods that can be used:

Ziegler Nichols Method: Classic approach which involves increasing the P Gain until the System reaches Marginal Stability, then adjusting the gain I based on empirical guidelines.

Test-and-Error Modify the P-I gains incrementally while watching the system's behavior in order to determine the best combination.

Software Tools: Use simulation software or libraries for microcontrollers to automate tuning.

Steps to Tuning

Start with a small P gain, and increase it gradually until oscillations are observed.

Introduce the I gain in incremental steps to eliminate steady-state error without destabilizing your system.

Adjust the parameters of the system to achieve a balance between speed, accuracy and stability.

4. Case Studies and Examples

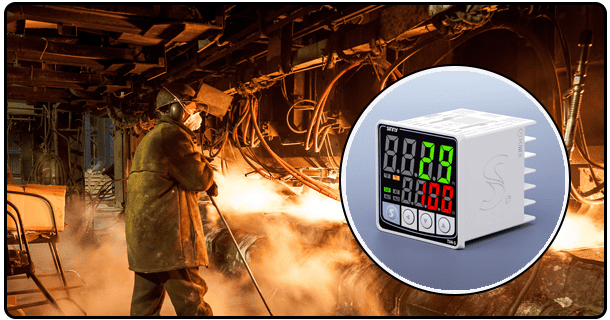

Industrial Furnace Control For a high-quality product, it is important to regulate temperature precisely in an industrial furnace. Engineers tuned the P-I gains in a PID control to achieve a stable and rapid response when temperature is changed, minimising energy consumption, and maximising process efficiency.

Case study 2: Arduino Home Brewing System A homebrewer implemented a PID Controller on an Arduino Board to regulate temperature. They achieved consistent conditions for brewing by carefully adjusting P and I gain.

The examples above demonstrate the importance of P-I gain tuning for improving system performance and reliability.

5. Problems and solutions

There are several difficulties in tuning P and I gain, such as:

Instability An excessive P or I gain can lead to oscillations, and loss of control.

Interactions Complexes: The interaction between the P and I gain complicates tuning.

Adjustments that Take Up Time: Manual adjustments can take up a lot of time and be error-prone.

Take on these challenges

Automate the tuning process by using automated tools.

Temperature measurement is more accurate when you use high-resolution temperature sensors.

Understand the dynamics of your system to help guide you in parameter adjustment.

6. The conclusion of the article is:

The P-I gains of PID temperature controllers are essential to their effectiveness. They allow for precise and stable control across many applications. The proper tuning of these variables ensures the best system performance by balancing accuracy, speed and stability. Innovative tools and techniques are being developed to streamline tuning as PID technology evolves. This will lead to improved efficiency and reliability of temperature control systems.

- Tiroma PID Temperature Controller - Precision Temperature Management

- The Comprehensive guide to temperature PID controllers and microcontroller integration