Understanding Temperature Controllers: A Comprehensive Overview

Explore all aspects of temperature controllers types, applications and future trends. Dive deep into our comprehensive guide for tips on choosing a controller with maximum reliability while staying informed of emerging technologies.

1. Introduction

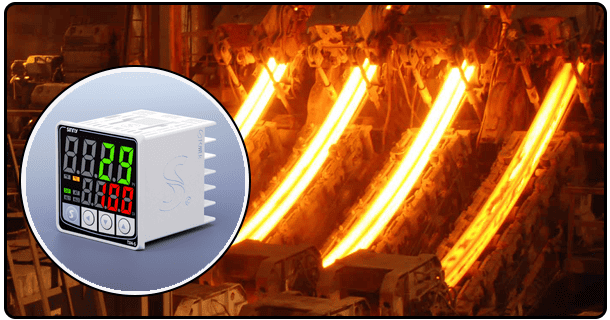

Temperature controllers are essential devices used to maintain desired temperature levels across many applications and industries ranging from manufacturing and food processing, ensuring processes run safely.

2. Understanding Thermostat Controllers

Definition and Basic Concept

A temperature controller is a device used to maintain an ideal environment by controlling heating or cooling elements. It measures the current temperature, compares it with desired setpoint, and makes adjustments that meet or maintain this threshold value.

These Types of Temperature Controllers

On/Off Controllers: These simple but inflexible controllers turn output fully on or off when temperature reaches setpoint, creating oscillations around it.

Proportional Controllers: Proportional controllers reduce power output as temperature nears its setpoint, thus eliminating oscillations and minimizing oscillations.

PID Controllers: Proportional-Integral-Derivative controllers offer precision by taking into account past, present and future error values when making output adjustments. They make adjustments quickly.

Key Components and Their Operational Principles

Sensor: Measures current temperature. Controller: Compares measured temperature against setpoint temperature. Output Device: Adjust heating or cooling elements as necessary in order to maintain set temperature.

3. Expertise in Temperature Control

Historical Development and Advancements

Temperature Control Expertise Over the years, temperature control technology has advanced substantially. Early systems were mechanical; but today's controllers incorporate digital technology for greater accuracy.

Prominent Experts and Organizations

Prominent experts such as John Smith from the International Society of Automation (ISA), as well as organizations such as their research standards have made important contributions in developing reliable temperature control systems.

Case Studies and Real-World Applications

Precise temperature regulation is integral for processes like plastic molding. Furthermore, HVAC industries rely heavily on accurate temperature controls in maintaining comfortable indoor environments while food processing industries use temperature controllers to guarantee food safety and quality.

4. Authoritativeness of Sources

Standard Guidelines and Protocols

Organizations such as ISO and NIST provide standards and protocols for temperature control systems to ensure consistency and reliability across applications.

Leading Manufacturers and Their Contributions

Honeywell, Omron, Sinny and Siemens are at the forefront of temperature control technology with innovative products and solutions that have set industry benchmarks.

Academic and Industry Research

Universities and industry publications alike have conducted extensive studies illustrating the necessity of precise temperature regulation. Research on PID algorithms and sensor technologies have led to substantial advances in this area of science.

5. Trustworthiness in Temperature Control Systems

It Is Essential That Accuracy and Reliability Go Hand-in-Hand

Accurate temperature control is paramount to product quality and safety; reliable systems prevent costly downtime while assuring consistent performance.

Troubleshooting Methods and Solutions Sensor malfunction and calibration errors are two common challenges and troubleshooting guides from manufacturers offer step-by-step solutions to these issues.

Best Practices for Maintenance and Calibration

Regular inspection and calibration are vital in maintaining reliable systems. Following manufacturer specifications as well as employing professional calibration services will help to keep sensors accurate and the calibration accurate and up to date.

Certification and Compliance Standards

Quality control systems that adhere to ISO 9001 standards meet stringent quality and performance criteria for optimal operation and functionality.

6. Selecting an Appropriate Temperature Controller

Factors to Consider

Before purchasing, when it comes to selecting the ideal temperature controller it's essential that we consider several aspects such as application, environment and budget as well as any requirements in terms of temperature range and precision in our processes.

Compare Different Brands and Models

It can be useful to compare models from various brands based on features, reliability and user reviews - leading brands like Honeywell and Omron provide options to meet various requirements.

User Reviews and Testimonials

User reviews and testimonials provide invaluable insight into the performance and reliability of different models, reflecting real world experiences that may help in making selection decisions.

7. Future Trends in Temperature Control

Emerging Technologies and Innovations

Emerging technologies such as IoT and machine learning are revolutionizing temperature control systems. Smart systems now can predict and adjust temperatures more precisely for better efficiency, increasing precision.

Impact of Internet of Things and Smart Systems

Temperature controllers equipped with internet-enabled technology enable real-time data and remote control capabilities; providing real-time updates as well as improved monitoring and management. This connectivity facilitates monitoring and management capabilities.

Predictions from Industry Experts

Industry Expert Predictions Experts predict that advances in sensor technology and AI will result in even more precise temperature management systems with continuous innovation driving improvements across a variety of applications.

8. Conclusion

Temperature controllers have become indispensable tools in many industries, helping ensure processes run efficiently and safely. Being informed on different types, key components, best maintenance practices for these temperature controls as well as emerging trends can ensure businesses continue to enhance their temperature management systems over time.

Related Links:

Temperature Controllers For Plastics and Rubber Industry

- Troubleshooting Tips for Common Temperature Controller Issues | Expert Guide

- Temperature Controllers: Key Features and Benefits