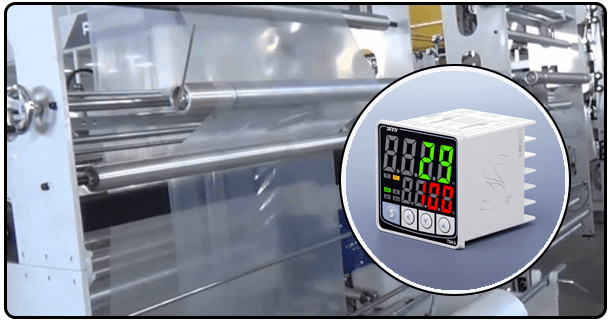

What Are Industrial Temperature Controllers, Their Types, Benefits & Applications

Please learn about industrial temperature controllers: their applications, benefits & future trends across various industries as they improve product quality & efficiency.

1. Introduction

Temperature regulation in industrial settings is crucial to product quality and process efficiency, making industrial temperature controllers essential devices that help achieve this by maintaining temperatures within predefined parameters. Here, we explore what an industrial temperature controller is and their types, applications, benefits, and future trends.

2. Definition and Basic Function

Industrial temperature controllers help ensure an exact temperature within processes by taking input from temperature sensors and making adjustments based on them to reach their goal temperature. Components that make up such controllers include sensors, controllers, and actuators - each performing one or more duties: monitoring directly while processing related data or making necessary alterations accordingly, with actuators making any required alterations.

3. Types of Industrial Temperature Controllers

On/Off Controllers are among the most accessible temperature regulators, activating heating or cooling devices when their temperature meets an established threshold. Cost-efficient but best used only in cases when precise regulation is less critical, On/Off Controllers provide simple temperature regulation solutions.

Proportional Controllers:

Proportional controllers offer more precise temperature regulation by adapting output proportionally to differences between set points and actual temperatures, thus decreasing oscillations around their set point for more stable temperature regulation.

PID Controllers:

PID (Proportional-Integral-Derivative) controllers offer precise temperature regulation through their combination of proportional control, integral action, and derivative actions to correct errors while keeping desired temperatures stable without excessive fluctuations. PID controllers have become industry favorites and continue to enjoy great popularity today.

4. Applications in Various Industries

Temperature Control in Different Industries Pharmaceuticals:

To preserve drug efficacy and ensure production efficiency, temperature controllers are integral to manufacturing and storage operations. Industrial temperature controllers integrate seamlessly into these activities as part of production or inventory systems.

Temperature Control in Food Processing:

To produce safe, top-grade products, temperature controllers are an integral component of food production by maintaining ideal temperatures throughout all stages - cooking, cooling and storage included - of production.

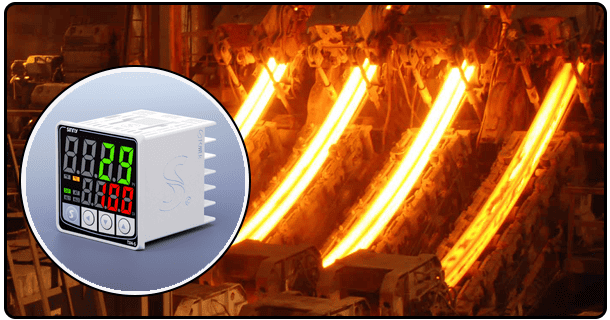

Temperature Control in Chemical Manufacturing:

Temperature controllers provide ideal environments to ensure consistent reactions and product quality during chemical manufacturing, with industrial temperature controllers offering precise temperature settings required by various processes.

HVAC Systems:

Heating, Ventilating, and Air Conditioning (HVAC) systems utilize temperature controllers to help create comfortable indoor climates that increase efficiency in residences, commercial properties, industrial establishments, and hospitals. Temperature controllers help create ideal comfort temperatures within these buildings.

5. Benefits of Using Industrial Temperature Controllers

Temperature Controllers Can Improve Product Quality:

By maintaining constant temperature regulation throughout processes, temperature controllers help produce higher-quality products with greater consistency of results.

Energy Efficiency:

Optimizing temperature controls to save energy can lower energy use, saving costs while simultaneously decreasing ecological impacts.

Temperature controllers are essential in safeguarding equipment and processes from overheating or any temperature-related risks that might impede their operations.

Temperature controllers present significant cost-cutting opportunities by eliminating waste and increasing operational efficiency - providing substantial cost-reduction potential while increasing profits and ultimately decreasing production costs and raising profits.

6. Key Components and Technology

Temperature sensors, such as thermocouples or RTDs (Resistance Temperature Detectors), measure and transmit temperature measurements directly to a controller for further action.

Controllers:

On/off, proportional, and PID controllers use sensor data to make necessary adjustments and implement essential course corrections.

Actuators:

Actuators are devices that adjust heating or cooling elements according to their controller to keep temperatures within their desired range.

7. Industry Standards and Certifications

The ISO 9001 certification certifies temperature controller manufacturing processes meeting international quality management standards.

Temperature Controllers Must Meet Additional Standards and Certifications: Depending on their industry or application, temperature controllers may need to comply with additional standards and certifications to provide quality operations while remaining safe for their users.

Future Trends in Temperature Control Technology

Advancements in Digital Controllers: Connecting IoT (Internet of Things) devices and intelligent systems revolutionize temperature management capabilities while expanding temperature management options.

Miniaturization:

Temperature controllers tailored explicitly for modern industrial uses are now being created in smaller sizes.

Sustainability:

Reducing environmental impact has become a top priority, emphasizing eco-friendly temperature control solutions with minimal ecological footprint.

8. Conclusion

Industrial temperature controllers are essential in providing accurate temperature regulation across industries, helping improve product quality, increase energy efficiency, ensure safety, and cut costs. With today's advancements, more sophisticated temperature controls provide even more benefits to industrial processes.

FAQ

1. What Is an Industrial Temperature Controller (ITC)?

An industrial temperature controller, commonly called "ITC," maintains accurate process temperatures by accepting input from sensors and making necessary modifications based on this input - for instance, adjusting heating or cooling elements accordingly.

2. What types of industrial temperature controllers exist? Three general categories of temperature controllers are found within industry settings: On/Off Controllers, Proportional Controllers, and PID Controllers, each offering various degrees of precision and control.

3. Why are industrial temperature controllers essential? Industrial temperature controllers are integral in maintaining consistent product quality, improving energy efficiency and safety measures while decreasing operational costs by keeping temperatures ideal for optimal operations.

4. What industries use industrial temperature controllers? Pharmaceutical, food processing, chemical manufacturing, and HVAC systems use temperature controllers to maintain accurate temperatures within their environments.

5. What will the future trends for temperature control technology look like? Anticipated trends include improvements to digital controllers, integration of IoT networks into miniaturizing devices and more energy saving/environmental solutions being created.

- Case Studies on Advanced Temperature Controllers Improving Industrial Efficiency

- Understanding PID Control in Industrial Temperature Controllers