What Are The Advantages Of PID Temperature Controllers?

Exploit the full potential of industrial automation with PID Temperature Controllers. Discover their precision, energy efficiency, and versatility when applied to process control and system stability enhancement.

Introduction

PID temperature controllers (Proportional-Integral-Derivative controllers) are sophisticated devices various industries use for precise process control. Their exact nature helps businesses increase efficiency, reliability, and quality while decreasing operating expenses. Here is more insight into their uses:

PID temperature controllers are essential components of industrial control systems. Their precision in maintaining control over process variables like temperature, pressure, or flow rate is unparalleled. This is achieved through constant calculation and adjustment of control inputs that ensure process variables stay at their setpoint or desired levels.

Accuracy and Precision

PID temperature controllers boast remarkable accuracy compared to on/off controllers that only toggle the state of an element; in contrast, PIDs make adjustments according to an error that accrues over time (integral of error over time and derivative of error), providing much finer control that significantly lowers the margin of error.

The precision of PID temperature controllers is another key advantage, as it helps maintain process variables within tight tolerances to guarantee consistent product quality and product consistency across industries such as chemical reactions or food manufacturing. PID temperature controllers play a pivotal role in these areas as the temperature-specific nature of these industries necessitates accuracy from equipment.

Energy Efficiency

PID temperature controllers make significant contributions to energy efficiency. By optimizing heating and cooling elements, they reduce consumption while saving costs and mitigating the environmental impact of industrial processes. Their fine-tuning capability means energy isn't wasted by overheating or undercooling, which occurs with less sophisticated control methods.

Cost-Effectiveness

PID temperature controllers offer advanced capabilities at an amazingly reasonable cost, thanks to their non-reliance on heavy hardware and the use of smart algorithms for precise control—this makes them cost-efficient solutions for various industrial applications.

Implementing PID algorithms can be accomplished using various means, including software applications, thus making upgrading to PID control less of an investment commitment for many businesses. Due to their cost-effective nature and flexible implementation methods, PID temperature controllers offer businesses budget-conscious alternatives.

Stability and Responsiveness

PID temperature controllers offer considerable stability benefits when applied to systems. By adjusting control inputs based on a derivative of the error derivative, these controllers can prevent overshoot or oscillation that might compromise process stability or quality outputs.

PID temperature controllers are widely respected for their rapid response to system changes. Their real-time control input adjustment enables prompt responses to disturbances requiring immediate adjustments for control purposes, making this type of controller invaluable in processes requiring quick responses to stay in balance.

Versatility

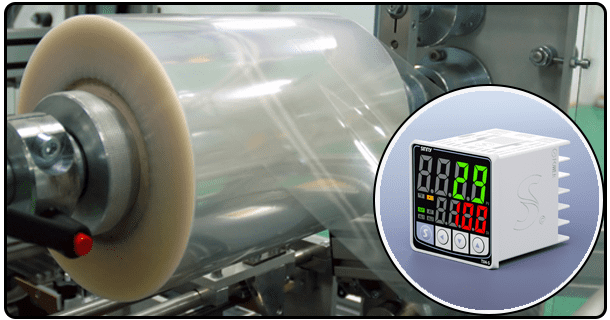

PID temperature controllers are extremely adaptable devices. Their use spans simple home appliances like ovens and refrigerators to complex industrial processes like chemical reactors or automotive control systems.

Another great advantage of PID temperature controllers is their adaptability: These controllers can be tailored specifically to each process's individual requirements—be they aggressive control to respond quickly to fast changes or more gentle regulation for more stable operations.

Ease of Use

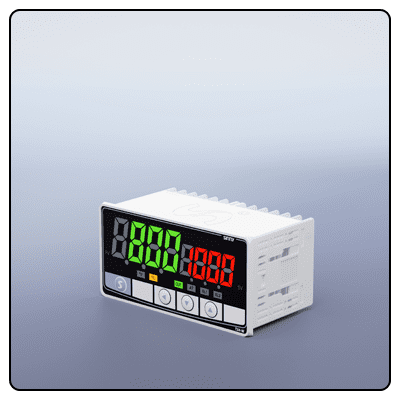

Modern PID temperature controllers are user-friendly. Many feature intuitive user interfaces that make setting parameters, monitoring processes, and making adjustments as needed easier. Thus, operator error is decreased while overall efficiency in control processes is improved.

PID temperature controllers' programmability maximizes their utility. Users can configure PID temperature controllers to suit specific processes and adjust as needed as industrial processes' needs change over time. With such flexibility ensured by PIDs' design, these solutions remain effective even as industrial processes' requirements shift over time.