What Does PID Stand For In Temperature Controller?

Discover the meaning of PID in temperature controller and how its components—Proportional, Integral, and Derivative—work together to achieve precise environmental regulation in industrial processes.

Precision and Temperature Regulation: Unlocking PID Temperature Regulation Systems

Maintaining optimal temperature conditions during industrial automation requires precision. PID control is one of the foremost temperature-regulating methods available today. But what exactly is PID, and why does it keep processes running smoothly? Join us as we explore Proportional-Integral-Derivative Control (PID).

1. The Essence of PID

PID stands for Proportional Integral Derivative control - three crucial elements that work in concert to produce optimal temperature regulation. Each component plays a unique role in temperature management systems when responding to deviations between desired setpoints and actual temperature values - known as errors.

Proportional Control (P)

PID's proportional part provides the first line of defense against temperature discrepancies by producing output directly proportional to any deviations from setpoint temperature when the temperature goes outside its designated parameters and deviates. Should temperatures deviate beyond their setpoint values, proportional control reacts proportionally and quickly returns them toward their setpoint levels if temperatures deviate further away, but sometimes integral and derivative parts must also be involved for precise setpoint attainment.

Integral Control (I)

Integral control is one of the three forces composing PID control. It summarises errors over time to inform current control efforts while correcting for ongoing drift, ultimately guaranteeing temperature reaches and stays near its setpoint over time.

Derivative Control (D)

PID's derivative component acts as the predictive eye, monitoring error changes at their rate before applying dampening force to dampen down system reactions and maintain stable temperatures despite significant delays. By anticipating what would come next and dampening unnecessary reactions early on, derivative control helps avoid overshooting its setpoint by providing foresight into system behavior that promotes stability over time lags.

2. PID Temperature Control

A PID temperature controller acts like a conductor, orchestrating inputs and outputs to create harmony in process temperature regulation. It calculates error values before applying corrections using weighted sums of proportional, integral, and derivative terms. This dynamic adjustment ensures temperatures stay within pre-set parameters while reacting quickly and precisely when fluctuations arise.

3. Components at Work

At the heart of every PID temperature controller lie several key components.

* Temperature Sensor: This sensitive device monitors actual temperature conditions.

* Controller Algorithm: This algorithm computes corrective action based on error signals and PID parameters to take corrective action when problems or error signals are detected in PID parameters.

* Actuator: An actuator adjusts system inputs like heater power according to what it receives from its controller's output.

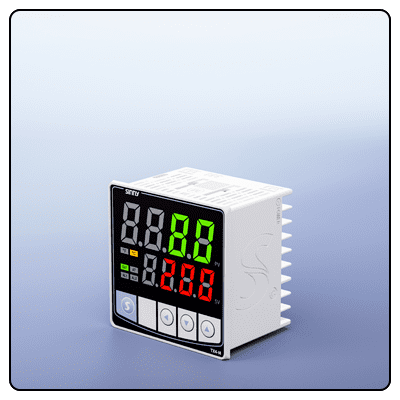

* Controller Interface: The controller interface is the user's portal for setting setpoints, configuring PID parameters, and monitoring their system.

The Principle in Practice

PID temperature controllers operate according to a principle of balance, constantly adjusting inputs to close any discrepancies between desired setpoint and actual temperature. They simultaneously manage proportional, integral, and derivative actions for precise temperature regulation across various industrial processes.

4. Temperature Controller Varieties

There are various forms of temperature controllers designed for specific uses; each provides distinct advantages:

* On/Off Temperature Controllers: this is the simplest form, providing binary output - either fully on or fully off.

*Proportional Temperature Controllers: Proportional controllers keep the setpoint at its set point by continuously adjusting output based on an error signal, eliminating extremes that on/off controllers create.

* PID Temperature Controllers: PID controllers offer precise control by integrating proportional, integral, and derivative actions for precise management.

- What Is Auto-Tuning In PID Temperature Controllers?

- What Are The Advantages Of PID Temperature Controllers?