Where to Buy Temperature Controllers: Top Retailers and Tips

Learn what a temperature controller is, how it works, and its various types and applications. Discover tips for choosing, installing, and maintaining temperature controllers for optimal performance.

Introduction

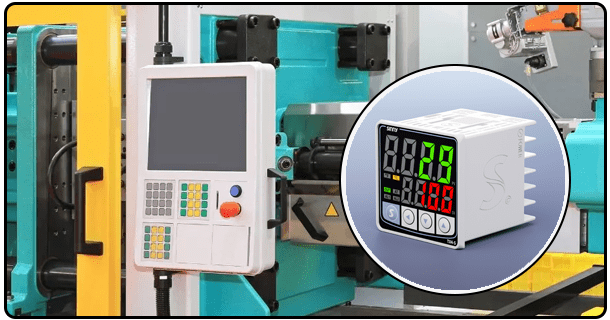

A temperature controller is an electronic device used to maintain an ideal temperature within an adjustable range. They play an indispensable role in industrial processes as well as household applications; from heating/cooling devices regulating with heating or cooling elements through thermostat controls to monitor safety/efficiency standards in cooling units or heaters regulated via temperature controls regulating heater/cooler ratio. In this article we'll look into workings of temperature controllers, their types, uses and how best to choose them for our own personal requirements.

How Temperature Controllers Work Temperature controllers follow an effective yet straightforward system for working: they monitor system temperatures using sensors and compare it against an ideal or desired setpoint temperature; should actual temperatures deviate, the controller activates an element such as heater or cooler to bring back to desired level.

Components Involved * Sensors: These devices detect current temperatures. Common examples are thermocouples, RTDs (Resistance Temperature Detectors), and thermistors.

* Control Elements: These devices adjust the temperature and may include heaters, coolers and fans.

* Controller Unit: This component serves as the brain of the system, processing sensor data and controlling elements to maintain their setpoint.

Types of Temperature Controllers

There are different kinds of temperature controllers suitable for specific uses or levels of precision, each tailored specifically for that task or application.

On/Off Controllers An on/off controller is one of the simplest types, acting to either activate or deactivate control elements when temperatures breach a setpoint temperature threshold. These types of controls are ideal for applications where precise control is not paramount.

Proportional Controllers

Proportional controllers offer more precise temperature regulation by adjusting output in proportion to any differences between setpoint and actual temperature, helping prevent fluctuations and maintain more stable temperatures overall. By adapting output according to difference, proportional controllers help provide precise temperature management without oscillation around setpoint resulting in smoother temperature regulation overall.

PID Controllers

PID (Proportional-Integral-Derivative) controllers are among the most advanced of temperature management techniques, employing proportional, integral, and derivative control mechanisms to keep temperatures consistent with high precision. PID controllers make PID ideal for industrial processes requiring tight temperature regulation.

Temperature controllers have many uses - both commercial and consumer alike.

Industrial Applications

* HVAC Systems: Heating, ventilating and air conditioning systems use temperature controllers to create comfortable indoor climates.

* Food Processing: Temperature control is of critical importance in food production to guarantee both safety and quality.

* Chemical Manufacturing: Precise temperature management is integral for chemical reactions that deliver quality product results.

Refrigerator Applications

* Temperature controllers in refrigerators help ensure fresh food.

* Air Conditioners: Air conditioners use temperature controllers to manage room temperatures.

* Aquariums: Temperature controllers create an optimal environment for aquatic life to flourish in.

Selecting an Appropriate Temperature Controller

Deciding upon an ideal temperature controller depends upon several variables, including its purpose, required accuracy and user friendliness.

Factors to Consider

* Accuracy: Depending on your application, precision in temperature control varies considerably; industrial processes might necessitate high precision while residential uses might allow more variation.

* Range: When purchasing an electronic controller for use with your application, verify it can meet the temperatures required in that range.

* Ease of Use: User-friendly interfaces and clear instructions can make setup and operation simpler, saving both time and resources.

* Compatibility: Confirm that the controller you select is compatible with all sensors and control elements you plan to use in your sensors/control system.

Installation and Set Up Proper setup and installation of a temperature controller require several steps for it to function effectively.

Basic Steps

1.

Mounting: When mounting the controller to its appropriate surface, make sure it can be easily reached while being protected from environmental influences.

2. Performing Maintenance, Cleaning or Replacement when Needed for Regular Operateon and Service and maintenance must also take place periodically and effectively as an essential maintenance process for an aqueduct is in operation (for example. water tank maintenance needs or replacing damaged water mains etc).

Wiring: Connect the sensors and control elements according to manufacturer instructions for wiring the controller.

3. Connecitioning: Set desired temperature setpoint and configure any additional settings such as alarms or timers before configuring any additional settings such as alarms. 4. Final Configuration

Calibration: Calibrate the controller to ensure accurate temperature readings and control.

Maintenance and Troubleshooting Regular inspection, upkeep and troubleshooting is essential to keep a temperature controller operating optimally.

Maintenance Tips mes * Routine Calibration: Perform regular calibration to maintain precision with your controller. This ensures it continues to deliver accurate control.

* Clean Sensors: For accurate readings, always ensure sensors are free from dirt or debris before beginning measurements.

* Inspect Connections Frequently: It is wise to regularly examine wiring and connections for signs of wear or damage.

Common Issues and Solutions

Inaccurate Readings: Recalibrate the controller and verify sensor placement before recalibrating.

*Controller Not Responding: Make sure the power supply and connections are undamaged before beginning this procedure.

* Temperature Fluctuations: To ensure that all control elements are operating as they should and that external factors don't hinder proper function of these controls, make sure they function regularly by performing temperature fluctuation checks regularly and check that no outside influences interfere with them.

Temperature controllers are indispensable tools for maintaining optimal temperatures across many applications, from industrial processes to household use. Understanding their workings, available types, and how best to select and care for one will enable you to make more informed decisions for meeting specific requirements. An excellent temperature controller ensures safety, efficiency, and optimal performance - regardless of its use for either purpose.

Conclusion

Temperature controllers are vital devices for maintaining stable temperatures in various applications. Understanding how they work, the different types available, and how to choose and maintain them can help you make informed decisions for your specific needs. Whether for industrial processes or household use, a reliable temperature controller ensures safety, efficiency, and optimal performance.

- What is PV and SV in a Temperature Controller? | Comprehensive Guide

- What is a Temperature Controller: Comprehensive Guide