What is PV and SV in a Temperature Controller? | Comprehensive Guide

Learn about PV (Process Variable) and SV (Set Value) in temperature controllers. Understand their roles, how they work together, and their applications in various industries

1. Introduction

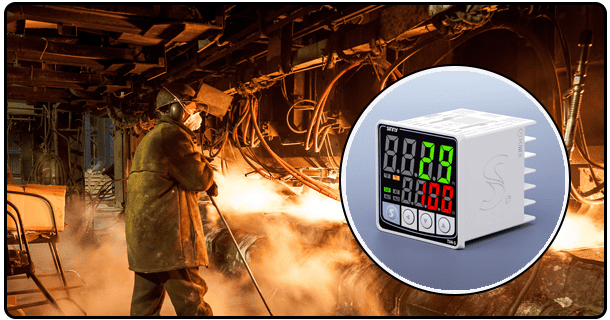

Temperature controllers are indispensable devices used in various industries and applications to achieve and maintain desired temperatures, helping processes run more smoothly by keeping temperatures within their targeted ranges. PV (Process Variable) and SV (Set Value) are two critical terms often encountered with temperature regulation; understanding them is imperative if working with temperature control systems.

Understanding Process Variable (PV) A Process Variable, or PV, refers to the current temperature measured by a temperature controller at any given moment and represents its state at that moment in time. PVs are continually monitored against desired values or Set Values to ensure systems operate within specified parameters.

Example of Temperature Measurement System; in a heating system, PV refers to the current room or material temperature that needs heating. Accurate measurement of PV allows temperature controllers to make necessary changes that maintain desired temperatures.

2. Understanding SV (Set Value)

A Set Value (SV) refers to the temperature that users wish for the system to achieve and hold; users set this goal based on requirements unique to a particular application or need.

Example: in an industrial production setting that calls for heating material at 200degC, the setpoint value (SV) would be set accordingly and then the temperature controller adjusted the heating elements so as to achieve PV closest possible matching to SV.

How PV and SV Work Together

Temperature control systems depend heavily upon PV-SV interactions for accurate climate regulation. A temperature controller compares PV with SV constantly and makes adjustments as necessary in order to minimize differences between them - known as feedback control.

When PV drops below SV, the controller activates heating elements to increase temperature; conversely if PV increases beyond SV then cooling mechanisms might be added or heating reduced accordingly to bring temperature back down. With constant adjustments like this in place, systems stay within their desired temperatures with stability and efficiency guaranteed.

Temperature controllers with PV and SV settings have many applications in temperature regulation, including:

* Industrial Applications: Temperature control in industries such as plastics, food processing and pharmaceuticals is absolutely vital to product quality and safety. Temperature controllers ensure processes like extrusion, baking and chemical reactions take place at their optimal temperatures ensuring optimal product output and safety.

* Household Applications: Many household appliances such as ovens, refrigerators and air conditioners utilize temperature controllers to maintain safe temperatures within an ideal temperature range for optimal functioning and user comfort.

* Scientific Research Applications: Temperature control in laboratories is crucial for experiments and processes that require specific conditions, with temperature controllers helping maintain an ideal environment to produce accurate and reproducible results.

Common Issues and Troubleshooting Temperature controllers may still experience issues that cause discrepancies between PV and SV temperatures, leading to discrepancies between output values. Such discrepancies could include:

* Sensor Malfunctions: Faulty sensors may produce inaccurate PV readings and cause improper temperature regulation, so regular calibration and maintenance is vital to ensure precise measurements.

* Controller Settings: Improper settings or parameters in a controller may cause it to respond inappropriately when responding to changes in PV production, creating issues. Reviewing and adjusting controller settings can help address such problems.

* Environmental Factors: Exposure to environmental elements such as ambient temperature changes or airflow fluctuations may adversely impact PV performance, making ensuring a stable setting around temperature-controlled systems essential to accurate control and precision management.

3. Conclusion

Understanding the roles of PV and SV in temperature controllers is fundamental for effective temperature management in various applications. By continuously monitoring and adjusting the PV to match the SV, temperature controllers ensure processes run smoothly and efficiently. As technology advances, temperature control systems will continue to evolve, offering even greater precision and reliability.

- What is a PID Temperature Controller? | Comprehensive Guide

- Where to Buy Temperature Controllers: Top Retailers and Tips