220V Digital PID Temperature Controller:Precision in Temperature Control

1. Introduction

Features

This digital temperature controller has innovative features which set it apart. They include:

Compatibility with 220V AC Power: This product is designed to be compatible with 220V AC power systems. It can therefore be used in global applications.

Digital Interface : Allows for precise temperature adjustment and monitoring in real time.

Sensor Integration Compatible with RTDs and thermocouples for accurate temperature measurement.

Adjustable setpoints: Enables the user to fine-tune PID (Proportional Integral Derivative).

Safety mechanisms: Includes over temperature protection to protect equipment and operator safety.

The controller is versatile, efficient and can meet the needs of a wide range of users.

2. Working Principle

The PID controller operates based on three core principles--Proportional, Integral, and Derivative control. This is a simplified version:

Proportional control: Achieves output in proportion to error (difference between the desired temperature and actual temperature).

Integral control: This eliminates steady-state error by adding up the errors over time, and then adjusting output to match.

Control : Responds to rate of error change, preventing oscillations or overshooting.

The controller regulates temperature precisely by utilizing feedback loops. Sensors such as thermocouples give real-time information that the controller can use to adjust. These adjustments are reflected in the heating elements and actuators.

3. Application

It is suitable for a wide range of applications.

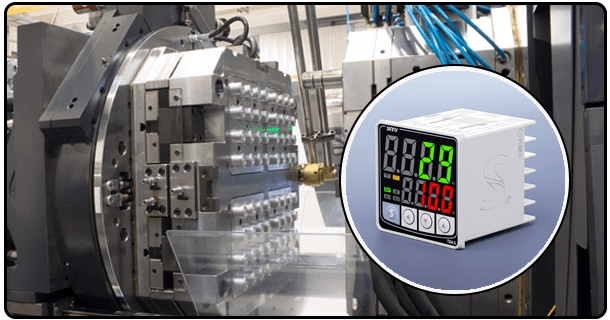

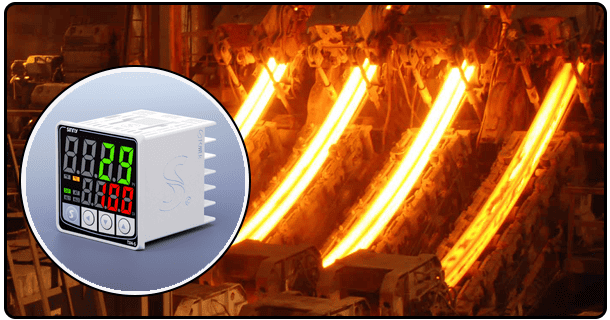

Industrial Heat: Used for processes such as plastic molding, metal heating treatment, and chemical manufacture.

Home appliances : Used in electric water heaters and ovens that require precise temperature control.

Laboratory equipment: Maintains a stable temperature within incubators and testing chambers.

The versatility of this technology in different areas highlights its significance for modern technology.

4. Benefits

Multiple benefits can be gained by using a digital temperature control with PID at 220V:

Precision: Acquires unmatched accuracy when it comes to temperature control. This helps reduce fluctuations, and improves product quality.

Efficiency Optimized heating cycle results in reduced energy consumption and operating costs.

User-Friendly Digital Interface: Easy to use digital interface that simplifies operations and adjustments.

Security: Integrated protection features improve operational safety by reducing the risks of high temperatures.

The controller is a popular choice among professionals as well as hobbyists.

5. Install and Setup

Following these simple steps makes it easy to set up a digital 220V PID temperature control:

Wiring Connect the controller according to the instructions in the manual to the sensor and actuator.

Configuration : Enter desired setpoints, and modify PID parameters according to the requirements of your application.

Safety measures: Make sure that you have the proper grounding and insulation to avoid electrical hazards.

Users should also test their setup regularly for optimal performance, and adjust as necessary.

Troubleshooting and Maintenance

Regular maintenance of the controller is essential to its efficiency.

Calibration of Sensors: Calibrate sensors periodically to ensure accuracy in temperature readings.

Firmware Upgrades: Install the latest firmware to gain access to new features.

Troubleshooting:

Overshooting : Adjust derivative parameter to stabilize temperature

Sensor errors: Check connections and replace any faulty sensors.

Maintenance that is proactive can extend the life of your controller, and reduce downtime.

6. Compare with alternatives

The digital PID offers many advantages over analog controllers or other methods of temperature control.

Analog vs. Digital : Analog controllers offer less precision but are easier to use.

Other Methods Unlike thermostats that maintain a temperature range set, PID controllers adjust dynamically in order to maintain and achieve the precise temperature.

These comparisons highlight the superiority digital PID controllers for complex applications.

This 220V digital temperature controller is a perfect example of innovation and precision. The advanced features and wide range of applications make this a very useful tool in temperature control. It is a reliable and efficient solution for laboratory or industrial equipment as well as household appliances. This technology offers enhanced safety and productivity, making it a top solution for temperature control.

Discover the benefits and uses of digital PID temperature controls. "Achieve accurate and efficient temperature controls for industrial, household, and lab use."

- RS485 Modbus PID Temperature Controller | Precision Meets Connectivity

- How to program a PID temperature controller