RS485 Modbus PID Temperature Controller | Precision Meets Connectivity

1. Introduction

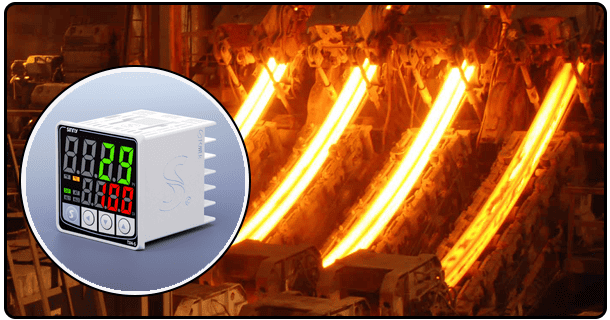

Digital control systems have revolutionized the way industries manage critical processes, such as temperature.

Features

The RS485 Modbus PID Temperature Controller is a highly sophisticated device designed to satisfy the needs of industrial environments. The main features of this controller are:

Modbus Support for RS485: Seamlessly integrated with other devices, enabling multi-device communications and real-time exchange of data.

Advanced Digital Interface : Allows for precise temperature control and real-time monitoring.

2. Working Principle

Its effectiveness lies in the combination of PID and RS485 Modbus communications. Each component is explained below:

PID control

proportional : This adjusts output according to the difference between the desired temperature and the actual temperature.

Integral: Compiles errors in order to remove persistent discrepancies and ensure accuracy at steady state.

Derived: It predicts errors in the future by analysing rate of changes, and prevents overshooting.

Modbus Protocol RS485

Utilizes differential signals to communicate over long distances, minimising noise and assuring reliable data transmission.

Connectivity between devices is made easier, and central monitoring and control are possible.

3. Application

Industrial Automation : Controls temperature in various processes, such as plastic molding, heat treating metals, and food processing.

HVAC System: HVAC systems that maintain a constant temperature for comfort and efficiency.

Lab Equipment: Controls temperature in autoclaves and incubators. This is crucial to scientific accuracy.

The controller plays a vital role in industrial and scientific environments.

4. Benefits

Engineers and technicians prefer the RS485 Modbus PID Temperature Controller for its numerous benefits.

Scalability : Suitable for complex industrial systems with multiple controllers.

Energy Efficient: Reduces energy costs and consumption by optimizing heating or cooling cycles.

Easy to Use: Features a user-friendly interface that makes it easy to set up, operate, and maintain.

The controller is a valuable tool in today's technological world.

5. Install and Setup

To ensure optimal performance, you must follow a number of steps when setting up RS485 Modbus PID Temperature Controller:

Wiring:

Configuration:

Modbus addresses, Baud rates, and Parity Settings should match your network configuration.

Adjust the PID parameters based on your application requirements to obtain desired control behaviour.

Sensor calibration: Regular calibration is essential for accurate PID controls.

Communication checks: Check the integrity of RS485 connectors to avoid data transmission problems.

Firmware updates: Update the firmware of your controller to gain access to new features.

Troubleshooting common issues

Communication errors: Check wiring and Modbus parameter to fix connectivity issues.

Oscillations or Overshooting: Adjust PID parameters for temperature stabilization.

Maintenance is best done in a proactive manner to ensure the system will continue working reliably.

Compare with alternatives

The RS485 Modbus PID Temperature Controller has distinct advantages over other technologies:

6. Modbus RS485 vs. other protocols

RS485 Modbus has a higher level of reliability for communication over long distances in industrial environments compared with Ethernet. Ethernet is less resistant to interference.

It allows for multi-device communications, as opposed to simpler protocols such as CAN.

Digital PID Controllers vs. Analog Controllers:

Analog controllers have fewer features but are easier to use.

Temperature control methods

PID thermostats are more accurate than basic thermostats because they dynamically regulate the temperature to ensure that it is maintained at the exact level.

The comparisons show why RS485 Modbus PID Temperature Controllers are the industry standard.

The RS485 Modbus PID Temperature Controller is the perfect example of how precision and connectivity can be combined. The advanced features and applications of this controller, as well as its numerous advantages, make it a must-have in the modern industry. This controller is ideal for HVAC or lab use. It offers unparalleled accuracy and efficiency. This technology allows for streamlined operation and better temperature control. It is a leader in this field.

Explore the benefits and uses of RS485 Modbus PID Temperature Controllers. Get precise temperature control for laboratory and industrial use.

- SSR PID Temperature Controller – Precision Heat Management Guide

- 220V Digital PID Temperature Controller:Precision in Temperature Control