Advanced Applications of PID Temperature Controllers in Industry

Explore the advanced applications of PID temperature controllers in industry, their role in automation and robotics, and future trends that may alter their development. Any obstacles or solutions associated with their deployment for industrial success.

1. Introduction

PID temperature controllers represent precision engineering within industrial automation, playing an indispensable part in processes where temperature regulation is essential - be they delicate pharmaceutical lab operations or more robust metal foundry activities.

PID Controllers Play an Essential Role

PID controllers are widely recognized for their ability to maintain temperatures within narrow margins, helping industrial processes run more smoothly and efficiently. Their advanced control mechanisms react rapidly to even minute temperature variations - making them invaluable in today's fast-paced industrial environments.

Benefits of Advanced Temperature Control System

As industries progress, their need for advanced temperature controls increases exponentially. PID controllers meet this need with exceptional precision, stability, and efficiency, which is indispensable in safeguarding product quality, maintaining safety standards, and optimizing performance.

2. Advanced Control Strategies

Modern PID controllers boast features that go far beyond simple temperature regulation.

Explore The Overview of Advanced Features.

They include adaptive control algorithms capable of learning and predicting system behavior, self-tuning capabilities that adapt parameters for maximum efficiency, as well as integration into IIoT platforms that facilitate remote monitoring and control capabilities.

Adaptive Control and Self-Tuning

Adaptive Control and Auto Tuning of Machine Tools are two options available to users for optimizing the performance of automated machine tools.

Adaptive control technology enables PID controllers to dynamically adapt to changing process conditions. Self-tuning algorithms adjust control parameters in response to system or environment changes, providing reliable performance without manual intervention.

3. Integration of PID Controllers and IoT Platforms

Integrating PID controllers and IIoT platforms has opened up numerous possibilities for predictive maintenance, energy management, and enhanced operational insights, propelling industry toward smart manufacturing in general.

4. Enhanced Process Efficiency

PID temperature controllers go beyond simply managing temperatures; they also aim to do so as efficiently and cost-effectively as possible.

Optimize Energy Use Efficiency (ACEE)

One of the hallmark features of advanced PID controllers is their remarkable capacity to optimize energy use. Through micro-adjustments made in real-time, these controllers prevent unnecessary over-application of heat or cooling and, therefore, lower industrial operations' carbon footprints.

Sustainable Manufacturing

PID controllers play an essential part in supporting eco-friendly manufacturing practices in today's environmentally conscious era. They minimize product defects while optimizing resource use to support and help create eco-friendly production methods.

Case Studies of Efficiency Enhancements

Numerous case studies illustrate the impact of PID controllers on process efficiency. In the plastics industry, for instance, advanced PID temperature controls have led to significant energy cost and material waste savings, which directly improve bottom lines while decreasing environmental impact.

5. Precision and Quality Control

PID temperature controllers play an integral part in industries with stringent quality standards and must comply with them to meet them.

Semiconductor Manufacturing Operations

PID controllers play an indispensable role in protecting the semiconductor industry's manufacturing process by consistently meeting temperature conditions needed for fabricating semiconductors. Thus, they safeguard against product defects caused by microscale variations. They ensure temperature conditions necessary for fabrication are consistently met and protect production integrity through safeguarded manufacturing practices.

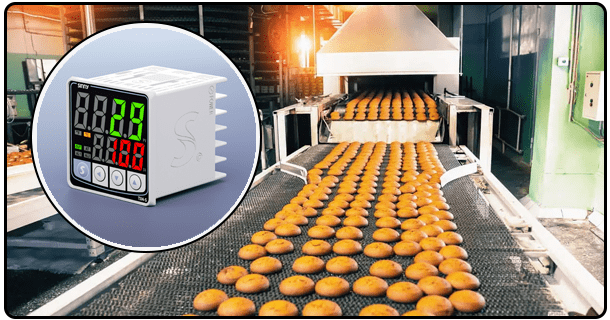

Pharmaceutical and Food Production companies

As is true for pharmaceutical and food industries, maintaining precise temperatures for product stability and safety are of utmost importance in these fields. PID controllers play an invaluable role in making sure products produced meet required specifications while adhering to stringent regulatory standards without waste or wastage occurring.

Compliance and Safety

PID controllers help the industry comply with safety regulations and quality certifications more easily by offering precise temperature-based process controls, thus lowering risks associated with noncompliance penalties and recalls.

6. Complex System Management

Advanced PID temperature controllers excel in overseeing complex systems with multiple variables and interactions that must be considered.

Multivariable Process Control Management

PID controllers have proven their worth in industries like chemical processing or metallurgy where processes may be affected by multiple variables at once, where processes require constant adjustment due to multiple elements simultaneously affecting them. They help keep stability even as several of them fluctuate simultaneously.

Management of Nonlinear Dynamics

PID controllers excel at managing nonlinear dynamics and process disturbances that arise in complex industrial settings, compensating their output accordingly to compensate for nonlinearities in order to keep systems on course.

Examples from Industry

PID controllers can play an essential role in chemical reactors where exothermic reactions produce rapid temperature shifts; their modulated cooling systems help prevent runaway reactions that threaten both product quality and equipment safety.

7. Automation and Robotics

PID temperature controllers represent an essential advance in manufacturing capabilities.

Enhancing Automated Systems

PID controllers play an indispensable role in advanced manufacturing for processes requiring extreme precision, like robotics, where consistent and accurate movement is essential. They ensure that the thermal aspects of these systems can be precisely managed, ensuring optimal system longevity and reliability of robotic equipment.

Automation will continue its upward momentum over the coming decade

Thanks to advances in artificial intelligence and machine learning technologies, PID controllers' role in automation will only continue to expand. PID controllers are becoming adept at anticipating system disturbances before they occur, thus providing preemptive adjustments that enhance process efficiency and product quality.

8. Challenges and Solutions

Implementation of advanced PID systems presents unique difficulties, particularly in complex industrial settings.

Addressing Implementation Challenges

These challenges include integrating PID controllers into existing systems, requiring specialist knowledge for tuning and maintaining these controllers, and increasing complexity within control systems.

solutions to common issues

Solutions involve extensive staff training and the design of more user-friendly PID controllers with intuitive user interfaces and advanced diagnostics tools to aid troubleshooting.

9. Conclusion

PID temperature controllers will surely play a vital role in shaping the future of the industry. Their advanced applications in improving efficiency, quality, and automation demonstrate this fact.

PID Controllers will play an increasingly prominent role in our lives over time.

PID controllers will continue to adapt as technology progresses, becoming even more integrated into their regulated systems and adaptable to the industry's ever-evolving needs.

- Mastering Industrial Precision: Maximizing Efficiency with PID Temperature Controllers

- Understanding the Basics of PID Temperature Control