Understanding the Basics of PID Temperature Control

Explore the essentials of PID temperature control with our in-depth primer. Learn how Proportional, Integral, and Derivative components work together to maintain precise temperatures in automated systems.

1. Introduction

PID temperature control has long been recognized for its key role in automated systems. Maintaining precise temperatures is required for operational success; PID stands for Proportional, Integral, and Derivative and provides a versatile control loop feedback mechanism. In this article, we seek to demystify these fundamentals of PID control while detailing its development from its inception into modern industry as an indispensable resource tool.

2. PID Controller At Its Core

A PID controller is an emblem of complexity in control theory, precisely regulating output to meet desired setpoints through error correction mechanisms that operate on error minimization principles - where errors refer to differences between measured variables and desired setpoints that need correcting. It operates using error compensation principles, and this difference between the measured variable and setpoint needs to be addressed through error reduction strategies.

* Proportional Control (P):

This component responds quickly and proportionately to present error to return quickly to its setpoint. Tuning the proportional response allows users to tailor it specifically for their system, ensuring larger errors have greater proportional responses for rapid return towards setpoint.

* Integral Control (I):

Integral control is the cumulative response to past errors. It addresses any steady-state residual mistake left over from proportional control by gradually integrating its error to eliminate persistent discrepancies and ensure that persistent differences between units disappear altogether.

* Derivative Control (D):

Derivative control anticipates future trends by considering the rate of error accumulation. In practice, however, derivative control acts more like an effective dampening force by dampening potential oscillations and preempting overshoot, ultimately reinforcing system stability and providing increased predictability of performance.

3. PID controllers serve as an excellent example of closed-loop control; their system continuously monitors and adjusts in response to feedback, in contrast to open-loop systems, which operate without such feedback.

Setting Up a PID Controller

Selecting and configuring an effective PID controller requires careful thought. You need to choose an optimal model suited to the specifications of the system being controlled and configure it. Hence, it works in harmony with its purpose of regulation.

Tuning a PID Controller

Tuning is an integral step to successfully using a PID controller. It requires fine-tuning P, I, and D values so they match the system's dynamics to achieve maximum performance and responsiveness.

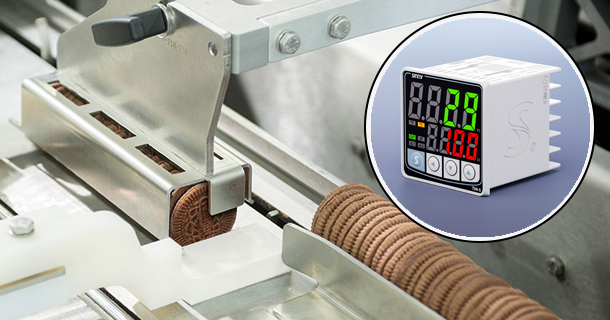

PID Temperature Control PID temperature control has many uses across industries, from semiconductor production to food processing. Its benefits in these settings can help increase efficiency and product quality while cutting down operational expenses.

Troubleshooting and Maintenance

Even well-configured PID systems may experience challenges over time. Common challenges can include sensor drift, external disturbances,, or component wear. Regular maintenance and a systematic approach to troubleshooting may help avoid many of these potential snags in advance and ensure the system's long-term reliability.

4. Conclusion

Mastering PID temperature control is an integral step toward unlocking its full potential. It provides the foundation needed to investigate more nuanced aspects that adapt and evolve with modern industry demands.

Related product links

- Advanced Applications of PID Temperature Controllers in Industry

- Temperature Regulation at its Finest: Benefits of PID Temperature Controllers