Analog PID temperature controller circuit: design, components, and applications

Learn the complexities of PID analog temperature controllers. Discover their design, components, principles of operation, tuning techniques, and application in the industrial, consumer and scientific sectors.

1. Introduction

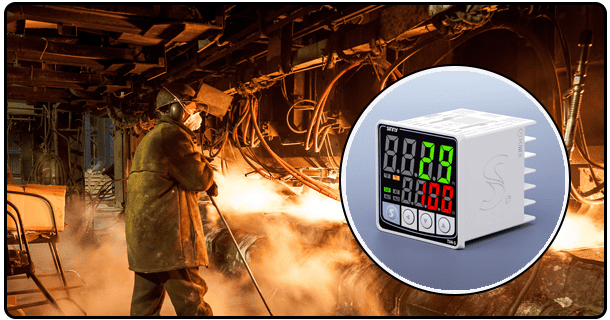

In many applications, including industrial, consumer, and scientific ones, temperature control is essential. PID controllers are an effective way to control temperature. The article highlights the components, designs, and applications of analog PID controllers.

2. Basics of PID control

The PID feedback loop is an advanced control mechanism that's widely used for industrial control systems. PID control continuously calculates the error as the difference between desired setpoints and measured variables, then applies corrections based on integral, derivative, and proportional terms. The derivative term is used to predict future errors. PID controllers are able to regulate temperature precisely by fine-tuning their parameters.

3. Analog PID temperature controller

The analog PID temperature control consists of several components.

Operational amplifiers (OpAmps). These are necessary for the signal processing and amplifying in the circuit.

Capacitors and Resistors These passive components determine the response characteristics in the PID controller.

RTDs or Thermistors: This sensor measures temperature and provides feedback to the controller.

Power Supply and Voltage Regulation : Provide constant power to the circuit for stable operation.

4. Circuit Design

Circuit design for an analog PID controller requires a schematic and the assembly of all necessary components. Op-Amps can be configured to calculate integrals, derivatives, and proportions. The time constants of each term are set by carefully selecting resistors and capacitors. Thermistors and RTDs measure temperature in real time, while the voltage is maintained by the power supply. A step-by-step tutorial will help you build a PID analog temperature controller that provides precise temperature control.

Working Principle

Analog PID temperature control operates by continually adjusting output in order to minimize error between desired and measured temperatures. A voltage proportional to temperature is generated by the thermistor. The Op-Amps use this signal to perform PID calculations. Op-Amps output drives an actuator to change the temperature. Feedback mechanism is used to ensure that system strives constantly to maintain desired temperature and compensates for disturbances.

5. Tuning the PID Controller

To achieve the best performance, the PID controller must be tuned by adjusting its integral, derivative, and proportional parameters. Tuning can be done in several ways, such as:

Test and Error : You can adjust parameters in small increments until you get the response that you want.

Ziegler Nichols Method : Systematic approach that involves setting integral and derivative gain to zero, and increasing proportional gains until the system oscillates. Calculate the PID parameters using both the oscillation period and ultimate gain.

Software Tool: Uses software to automate tuning based on system response.

To achieve optimal temperature control, it is necessary to balance the three terms in order to reduce overshoots, settle-time, and steady state error. Finding the correct balance between different systems, and compensating non-linearities are common challenges.

Application

The applications of analog PID temperature controls are numerous:

Industrial Application: Used for chemical processing, HVAC systems (heating ventilation and air conditioning), and manufacturing processes that require precise temperature control.

Applications for Consumers: Used in heating systems, appliances, and household products that need temperature control.

Science Applications: Used in laboratory equipment like incubators, autoclaves and environment chambers when accurate temperature control for experiments and researchers is required.

In many applications that require precise temperature control, analog PID controllers can be an indispensable tool. Understanding their design and operating principles will help you appreciate how effective they are at maintaining the desired temperatures. PID controllers will become even more important in the future as technology improves.

- PID temperature controller: design, components, and applications

- Universal PID temperature control controller