Explore How to Design an Effective Temperature Control System

Utilizing our in-depth guide, learn the secrets to building an efficient temperature control system with our step-by-step approach. Identify critical components, design considerations, and best practices for maximum performance of any given system.

1. Introduction

Temperature control systems are vital in manufacturing and food processing, ensuring optimal performance and safety for workers and products. Such systems maintain desired temperatures within specific ranges to prevent overheating or freezing, which could otherwise damage equipment or spoil products. This creates operational efficiency and reliability benefits for engineers and technicians in such fields. Understanding how to design effective temperature control systems is imperative to boost operational efficiencies and reliability.

2. Understanding Temperature Control

Temperature control refers to regulating a system or environment to meet an ideal setpoint temperature, using various forms of controllers like PID (Proportional-Integral-Derivative) controllers or on/off controllers. PID controllers are particularly well suited to maintaining stable temperatures through constantly adjusting control output based on differences between setpoint and actual temperatures - PID is widely considered the go-to controller due to their precision in keeping temperatures steady by making minor adjustments based on differences between setpoint and actual temperatures. PID controllers excel due to their precision while being used in many environments where PID control output adjustments automatically according to changes between setpoint and actual temperatures. On/off controllers are a great way of controlling systems or environments which need precise temperature regulation via dynamic settings to keep temperatures constant based on this difference between setpoint and actual.

Components of an Effective Temperature Control System

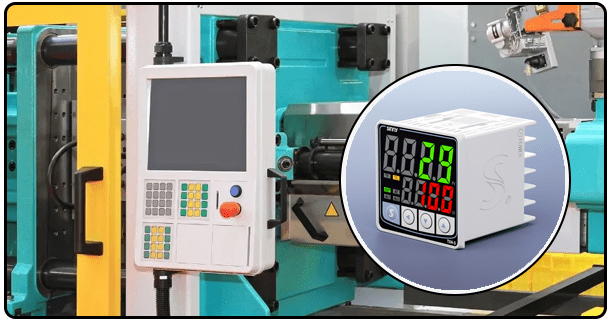

An efficient temperature control system comprises several essential elements. These components include:

1. Sensors: Temperature sensors such as thermocouples and RTDs (Resistance Temperature Detectors) measure temperatures accurately to provide feedback to controllers.

2. Controllers (such as PID controllers ) process sensor input and determine necessary adjustments to maintain desired temperature levels.

3 Actuators: Such components as heaters and coolers that execute commands given from controllers such as PID controllers to change temperatures accordingly

4. User Interface and Monitoring Tools: Interfaces that allow users to set parameters, monitor system performance, and make necessary changes as required.

3. Design Considerations

When developing a temperature control system, multiple factors should be taken into consideration to maximize effectiveness and reliability:

1. Sensor Placement: Proper sensor positioning is essential for accurate temperature readings. Sensors must be situated to reflect their controlled environments accurately.

2. PID Tuning: For optimal performance of any PID controller, proper tuning involves setting its proportional, integral, and derivative settings appropriately to respond quickly and precisely to temperature variations without overshooting or oscillating. This step ensures your system responds swiftly without overshooting or oscillating - something improper tuning may do if used poorly.

3. System Response Time: Balancing speed with stability is essential in any system; too rapid response can become unstable, while too slow reaction may fail to maintain desired temperatures efficiently.

4. Insulation: Effective insulation protects systems by limiting heat loss or gain and optimizing efficiency and accuracy.

4. Hardware Design

The design of a temperature control system involves selecting and integrating suitable components.

1. Select Sensors and Controllers: Select sensors and controllers that meet the unique requirements of your application - factors to keep in mind may include temperature range, accuracy, and response time.

2. Integrating Actuators: Make sure all heaters, coolers, and other actuators you select work seamlessly with their controllers to regulate temperature fluctuations effectively.

3. Wiring and Connectivity: For reliable communication among sensors, controllers, and actuators, proper w is established.

Software Design

Software design encompasses programming the controller and creating control algorithms:

1. Programming the Controller: Create software capable of processing sensor inputs, running control algorithms, and communicating commands directly to actuators.

2. Implementing Control Algorithms: Utilize PID control algorithms to achieve temperature stabilization at your facility and fine-tune their settings for the best performance.

3. User Interface Design: Create an accessible user interface that enables operators to set parameters, monitor system performance, and make necessary adjustments easily.

Testing and Calibration

Testing and calibration are vital steps in ensuring the system operates correctly:

1. Initial Testing Procedures: Conduct preliminary tests to ensure all components function as planned and that your system can achieve your desired temperature setting.

2. Calibration Techniques: Calibrate sensors and controllers to guarantee accurate temperature measurements and control.

3. Tuning Your System: Make any necessary modifications to control algorithms and hardware components to enhance system performance for optimal results.

5. Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential for the long-term reliability of the temperature control system:

1. Regular Maintenance Schedules: Establish maintenance schedules to continuously inspect and service sensors, controllers, and actuators.

2. Common Issues and Solutions: Recognize common problems like sensor drift and controller malfunction and devise strategies to resolve them quickly.

3. Upgrading Components and Software: Upgrade components and software regularly in order to take advantage of new technologies and enhance system performance.

Case Studies

Examining case studies of successful temperature control systems can provide valuable insights:

1. Manufacturing Industry: Temperature control was employed successfully in a manufacturing plant to enhance product quality while simultaneously decreasing energy usage, saving considerable costs in both areas of operation.

2. Food Processing Industry: Precise temperature management ensures food safety while prolonging shelf life at food processing facilities.

3. HVAC Systems: An academic research report detailing how advanced temperature control systems increase comfort and energy efficiency in commercial buildings.

Conclusion

Designing an effective temperature control system involves understanding its principles, selecting and integrating components carefully, testing, calibrating, and calibrating these systems to optimize operational efficiency, guarantee safety, and elevate product quality. Under these guidelines, engineers and technicians can craft systems that increase operational efficiencies, safeguard safety, and improve product quality.

- How to Calibrate a Temperature Controller for Accuracy

- Discover the Top Temperature Controller Brands to Trust in 2024