Explore Industrial Temperature Controllers for Pharmaceutical Production: A Comprehensive

Guide Learn the role of industrial temperature controllers in pharmaceutical production while becoming knowledgeable on their various types, features, and applications to match up best with your production requirements.

1. Introduction

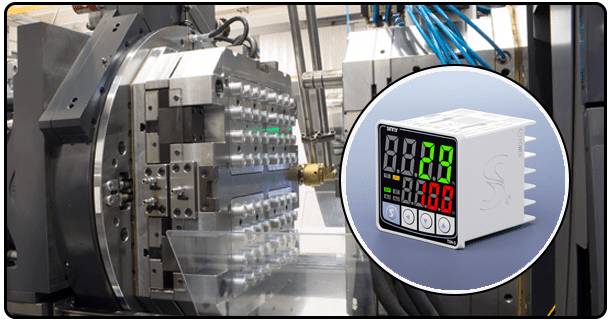

Temperature control is essential to pharmaceutical production, helping ensure product quality and efficacy. Industrial temperature controllers play an indispensable role in maintaining precise temperatures at various production stages. In this article we cover different kinds of current temperature controllers in pharmaceutical production and how you can select one tailored to meet your particular requirements.

2. Types of Temperature Controllers

In the pharmaceutical industry, various temperature controllers offer unique advantages and applications.

PID Controllers: Propo (PID) controllers have become widely utilized for their accuracy and stability. PID controllers use error values calculated every time there's a difference between setpoint variables and measured process variables while applying proportional integral and derivative terms for correction based on errors identified from past process variables - providing accurate temperature regulation during chemical reactions or fermentation processes.

On/Off Controllers: On/Off controllers offer cost-efficient temperature regulation solutions compared to PID controllers by switching on and off when temperatures pass a set threshold threshold threshold. While less precise, on/Off controllers make sense in basic heating/cooling systems where accur control is optional.

Programmable Controllers: Programmable controllers provide advanced features, allowing users to set multiple temperature profiles and schedules easily. Programmable controllers are ideal for drying or curing processes involving fluctuating temperatures over time; with flexible automation built directly in, programmable controllers help increase process efficiency for optimal results.

3. Temperature Controller Key Features

To select an effective temperature controller for pharmaceutical manufacturing, certain essential features must be considered to ensure optimal performance and dependability.

Accuracy and Precision: Accuracy and precision are paramount in pharmaceutical processes to maintain product quality while meeting regulatory standards. When looking for controllers with low tolerance levels and high-resolution sensors for increased compliance assurance.

Response Time of Temperature Controllers: Response time refers to how quickly temperature controllers respond to changes, making quick response times essential in dynamic processes where temperature fluctuations could negatively impact product quality or customer experience.

Durability and Reliability: Industrial environments can be harsh, with exposure to chemicals, moisture, and mechanical strain. You should select durable and reliable controllers to withstand these challenges without compromising your application environment.

User Interface and Connectivity: An accessible user interface and connectivity options are essential to making systems more straightforward to use and integrate into others. When searching for controllers that provide intuitive displays, remote monitoring capabilities, or compatibility with existing control systems.

4. Applications in Pharmaceutical Manufacturing

Temperature controllers are essential to pharmaceutical production processes to guarantee product quality and maximize process efficiencies.

Sterilization Processes: Temperature controllers play an integral part in effective sterilization procedures by ensuring autoclaves and other sterilization equipment work within their specific temperature parameters to minimize contaminants reaching harmful concentrations.

Reactor Temperature Control: Chemical reactions used in pharmaceutical manufacturing require carefully controlled temperature conditions in reactors; temperature controllers ensure these remain optimal, guaranteeing consistent and successful reactions.

Storage and Transportation: To preserve product efficacy, pharmaceutical products should be stored and transported at temperatures that don't allow product deterioration or cause efficacy loss during storage and transit. Temperature controllers are widely utilized by storage facilities and transport vehicles alike to monitor temperatures effectively to monitor temperatures effectively to maintain efficacy while transporting products from one facility or vehicle to the other.

Quality Assurance: Temperature controllers help manufacturers ensure consistent quality throughout production processes by controlling manufacturing conditions to lower risks of defects while meeting regulatory standards.

5. Benefits of Utilizing Industrial Temperature Controllers

Employing industrial temperature controllers provides several advantages in pharmaceutical production environments.

Precision Temperature Control Assures Product Quality: Precise temperature control ensures product quality by decreasing defects-related risks while increasing product efficacy.

Temperature controllers with faster response times and advanced features can significantly enhance process efficiency, decreasing downtime and increasing production rates.

Compliance With Regulation: Accurate temperature controls help meet industry and governmental standards and requirements without incurring additional fines or costly penalties.

Cost Savings: Temperature controllers offer substantial cost-cutting potential by cutting wasteful spending and improving process efficiencies, leading to significant cost savings while optimizing resource use and decreasing energy consumption.

6. Choosing the Right Temperature Controller

When you're looking for the ideal temperature controller, please consider your unique process requirements and environmental constraints when making this selection.

Assess Process Requirements: Please ensure your controller's capabilities meet those required for your process in terms of temperature range, accuracy, and response time.

Evaluation of Environmental Conditions: Select controllers capable of withstanding your environment - chemicals, moisture, or mechanical strain.

Consider Calibration and Maintenance: Regular calibration and maintenance are paramount for long-term accuracy and reliability. When purchasing controllers, they make this easier to service or calibrate.

Consulting Experts or Manufacturers: Involvement from industry professionals or manufacturers can be precious when searching for temperature controllers to suit your precise requirements, providing expert guidance to find the ideal options.

7. Case Studies and Examples

Studying real-life examples can give invaluable insight into how temperature controllers have been implemented successfully within pharmaceutical manufacturing facilities.

Pharmaceutical Industry Examples: Temperature control is vital when producing vaccines to preserve the stability and efficacy of active ingredients; temperature controllers are used in storage facilities to manage temperatures to ensure vaccines remain influential even over their shelf lives.

Lessons Learned: One pharmaceutical company successfully integrated PID controllers into their fermentation process, leading to improved product yield and consistency, lower waste output rates, and higher-quality goods produced under optimal fermentation conditions and at reduced waste costs. Through precise temperature regulation, they optimized fermentation conditions, resulting in higher-quality goods produced at reduced waste costs.

8. Conclusion

Temperature control is an integral component of pharmaceutical manufacturing, helping ensure product quality and efficacy. Industrial temperature controllers are essential in maintaining precise temperatures during different production stages and stages. By learning more about various controllers and their features and applications, you can make educated decisions to enhance manufacturing processes and achieve improved outcomes.

- How to Install and Calibrate an Industrial Temperature Controller: A Step-by-Step Guide

- Discover How Industrial Temperature Controllers Improve Product Quality