How PID Controllers Work: A Comprehensive Guide

Learn how PID controllers work, including their components, working principles, and applications. Discover tips for tuning and optimizing PID controllers for industrial automation.

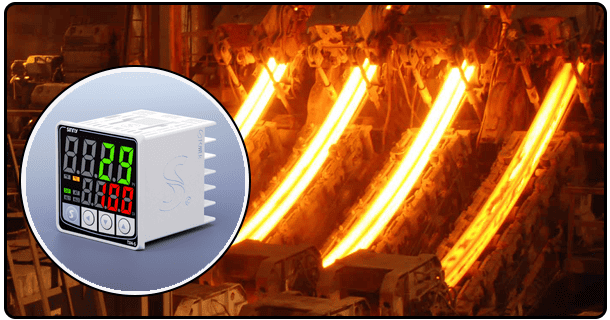

1. Introduction to PID Controllers

PID (Proportional-Integral-Derivative) controllers are widely utilized control loop feedback mechanisms used in industrial control systems. Their primary function is to maintain desired setpoint by minimizing error between setpoint and process variables - these PID controllers find use in applications like temperature, pressure and flow control where precise and stable regulation are crucial components.

2. Components of a PID Controller

Proportional (P) Component

The proportional component, also referred to as K_p or the proportional gain, adjusts control output proportionally in response to errors between setpoint and process variables. A higher K_p can yield larger correction for certain errors but setting too high an amount can cause system instability.

3. Integral (I) Component | Controller Output| Controller Output

The integral (I) Component addresses past errors by adding up and integrating errors over time into control output, effectively correcting residual steady-state error that cannot be eliminated through proportional control alone. An integral gain, K_i, determines how quickly past errors are addressed but excessive K_i may cause oscillation of system outputs.

Derivative (D) Component Its The derivative component responds to the rate of error rate change, forecasting future errors based on its current rate of change and dampening response thus reducing overshoot and improving stability of system response. K_d, or derivative gain determines its sensitivity while too much K_d can amplify noise in system.

4. Working Principle Feedback Loop

PID controllers operate within a feedback loop where process variables are continuously measured against their setpoint, then evaluated against any variances to ascertain an error value which will then be processed by PID's algorithm to produce control outputs.

Control Algorithm

A control algorithm uses proportional, integral and derivative terms to adjust processes. A PID control output (u(t)) formula follows.

$$u(t) = K_p e(t)+ K_i int(e(t)dt + K_d frac(de(t)dt.dt

$$ WHERE E(T) = Error at Time T, K_p is used as an immediate response, K_i corrects past errors accumulating over time, while K_d anticipates future errors by offering immediate anticipations.

5. Tuning a PID Controller

PID controller tuning is essential to optimal performance, and involves adjusting K_p, K_i and K_d gains to achieve desired response. Popular tuning methods include:

* Ziegler-Nichols Method: This heuristic approach requires setting all integral and derivative gains to zero while gradually increasing proportional gain until oscillation begins in order to calculate PID gains. Once oscillation begins, ultimate gain and period are used as references when calculating PID gains.

*Trial and Error: Step by step adjustments of gains while monitoring system response until finding an acceptable balance of stability and responsiveness is found.

6. Applications and Examples

PID controllers have proven their versatility in numerous industries due to their effectiveness, as seen in numerous real world examples including these ones:

* Temperature Control: PID controllers in HVAC systems maintain desired temperatures by adjusting heating or cooling elements accordingly.

* Pressure Control: PID controllers play an essential role in chemical processing operations by controlling pressure to ensure safe and efficient operations.

*Flow Control: In water treatment plants, PID controllers manage the rate and quality of flow for consistent quality control.

PID controllers offer several benefits, such as increased process stability, decreased variability and enhanced system performance.

- What Does a PID Controller Do? Understanding Its Functionality and Applications

- How to Set PID Values in a Temperature Controller